The future of long-haul trucking is accelerating autonomously on a freeway near you

Kodiak autonomous technology revolutionizes long-haul trucking. Learn more about Vicor power modules that drive mission critical ‘seeing’ sensors

The pace of automotive electrification has never been more aggressive and focused. To achieve their demanding goals, OEMs need to innovate like never before. They need to explore the impact of a modular power design.

Electric vehicles currently constitute about 11 percent of global vehicle production, a total that is expected to jump to 62 percent by 2030. About half are expected to be fully electric.

Credit Suisse projects about 63 million new vehicles worldwide by the beginning of the next decade, with an estimated 29 being all-electric. Industry observers note that growing power demand will further strain electrical grids.

In an interview, with Patrick Wadden, vice president of Vicor Corp.’s Automotive Business Development unit, stressed the need for strong investment in electrification and power technologies that will play a key role in solving powertrain efficiency challenges.

“Volvo is claiming that 50 percent of their vehicles will be electric, and the remaining ones are going to be hybrid by 2025. By 2030, Ford, GM and Chrysler are going to be investing over $50 billion. This year new vehicle estimates are even higher than last year,” Wadden added.

Figure 1: By 2030, battery electric vehicles (BEV) will account for 45% of all xEVs (Source: Credit Suisse estimates).

Car makers are electrifying some of their most popular vehicles, including the new Ford Mach E (the electric Mustang) and its flagship F150 truck, dubbed Lightning. The new vehicles include fast-charging technology while promising lower maintenance costs.

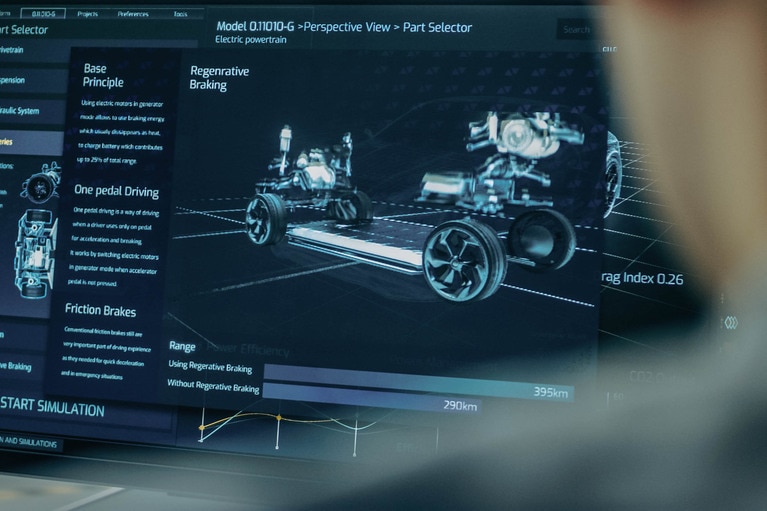

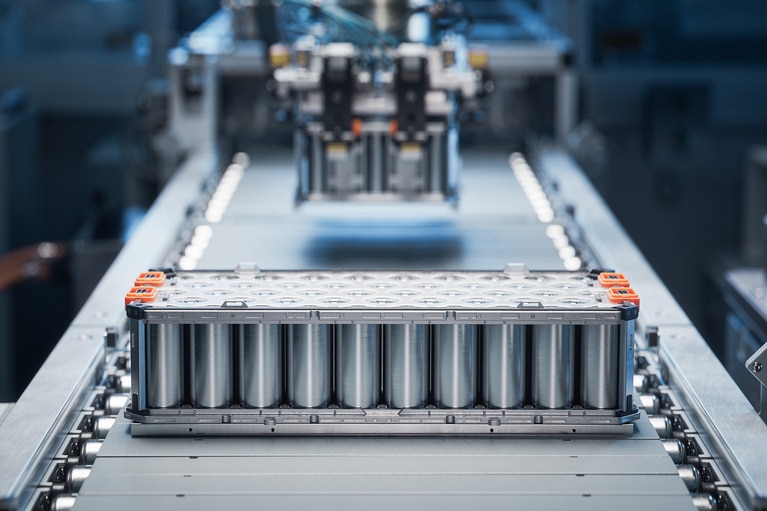

Electric power levels in cars with internal combustion engines typically range from 600W to 3kW. New EVs require power levels ranging from 3 to 60kW, or up to 20 times that of conventional vehicles. The increase represents a major challenge for power engineers trying to optimize power delivery networks. To meet those challenges, Wadden emphasized the need for lightweight, compact systems offering flexibility so power components can easily scale and be reused across fleets.

To maximize vehicle electrification, OEMs must increase power levels, reduce powertrain size and weight while improving thermal management and reusability. The choice of powertrain and charging is critical. Manufacturers are striving to optimize their power networks by investing millions of dollars in electrification R&D while iterating with new technology. For example, 48V power supply technology is rapidly expanding, both for fully electric and hybrid vehicles.

OEMs need to pack as much power as possible into a constrained space. “Vehicles need compact and efficient power solutions,” said Wadden. To achieve full-fleet electrification, OEMs need to be able to reuse designs across different platforms to speed deliveries. Scaling is essential when modifying power levels among sedans, minivans and SUVs that share the same platform.

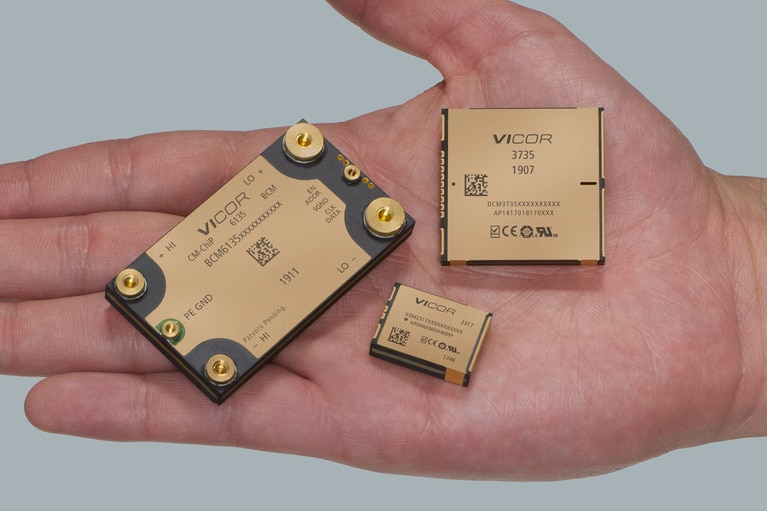

Overall vehicle weight affects performance, particularly battery life. Vicor is pitching a modular bus converter (BCM6135) billed as providing 98-percent efficiency via electrical interference filtering, decreased cooling and a 25kg 48V battery replacement case. The 61-by-35-by-7mm power module converts the primary battery from up to 800V to 48V, delivering more than 2kW of power with a power density of >4.3kW/in3.

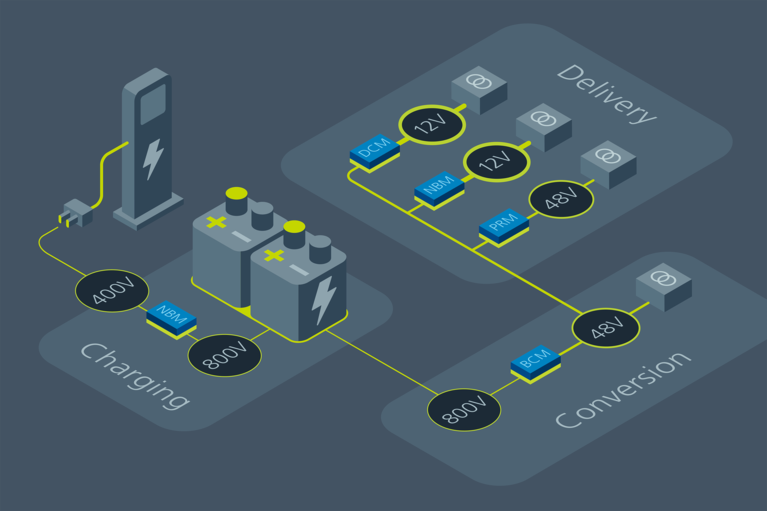

Figure 2: Power delivery networks using power modules reduce size and weight.

As vehicle electrification advances, design teams increasingly must consider changing power requirements. Wadden said a scalable, modular power system allows designers to implement standard approaches in a variety of EV powertrains. Modularity also allows distributed power architectures using a 48V bus. Power modules can be placed in alternate locations for localized 48V/12V conversion – for example, in a glove compartment, trunk or near each wheel.

Wadden added that qualification of vehicle electronic components represents a common delay in development. Delays can run up to three years. Hence, high-density power modules are promoted as reducing design qualification times.

“Innovation is needed in the form of new architectures and topologies that provide maximum performance today and can also be reused and reconfigured for the future,” said Wadden. “Integration is important. If you look at one of our modules that has 200 individual components inside, it’s a lot easier to qualify one module than it is 200 components. And so integration has a lot of merits.”

Many EVS are now using 800V primary batteries to meet the required power levels and deliver higher performance. Existing converters are bulky due to the high input-to-output voltage (800V to 48V) ratio. Fixed-ratio conversion modules like Vicor’s, operating at high switching frequencies, offer efficiencies of up to 98 percent, thereby reducing system size and weight. Decentralized architectures and modular power supplies for the distribution of the 48V power can help simplify designs.

Vicor automotive modules also can be connected in parallel. With the addition of a few others components, it is possible to boost a power delivery network from a few hundred watts to tens of kilowatts.

Power modules deliver distinct advantages, promising higher power density, flexibility and faster power system design.

This article was originally published by EE Times.

Automotive solutions: Converting the high‑voltage xEV battery to 48V or 12V

Article: Shrink the 12V battery by half and maintain cold crank?

Podcast: Tesla and Vicor discuss the crucial trade-offs made in automotive power systems design

Automotive products: The smallest, lightest power modules

The future of long-haul trucking is accelerating autonomously on a freeway near you

Kodiak autonomous technology revolutionizes long-haul trucking. Learn more about Vicor power modules that drive mission critical ‘seeing’ sensors

Automotive Engineering Exposition online 2024

Vicor to present latest power modules for 400V – 800V high-efficiency voltage conversion for electric vehicles

International Conference EEHE 2024, Germany

Vicor presented a solution for mitigating inverter ripple currents and voltage in electric vehicles at EEHE conference

High-performance power modules drive the battery lifecycle

Learn about the lifecycle of a battery and how high-performance, power dense modules are being used to reduce cost, size and improve efficiency