Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

We will be conducting maintenance on the website Feb.13th between 11:30am and 1:00pm EST. Some parts of the site maybe offline during this time. We apologize for any inconvenience and thank you for your patience.

For many equipment, the size and weight of electronic systems is a critical requirement. This is particularly obvious in applications such as aerospace, where additional size and weight in a drone, for example, reduces range and flying time. But most systems can benefit from smaller or lighter electronics. Power-system designers often focus their efforts to cut size and weight during the component selection process, but the reality is that at this stage only relatively small incremental improvements can be delivered.

Selecting the right power system architecture can have a much bigger impact than optimizing component selection for a particular design. The design of the power system determines the components and cabling required. For example, increasing the voltage used to distribute power reduces the size of the conductors required, which can be a significant factor in some applications.

The selection of power architecture can also have an impact on the components that need to be used, both active and passive, allowing large reductions in size and weight. Although the power density and weight of the converters is important, in many cases other components, from heatsinks to bulk capacitors, are bigger contributors to the power system’s overall size and weight.

The Factorized Power Architecture™ (FPA™) is a particularly interesting approach for applications that demand light weight, compact power systems. By eliminating bulk capacitance at the point-of-load (PoL) and replacing it with a ceramic capacitor earlier in the power chain, FPA delivers significant reductions in both size and weight.

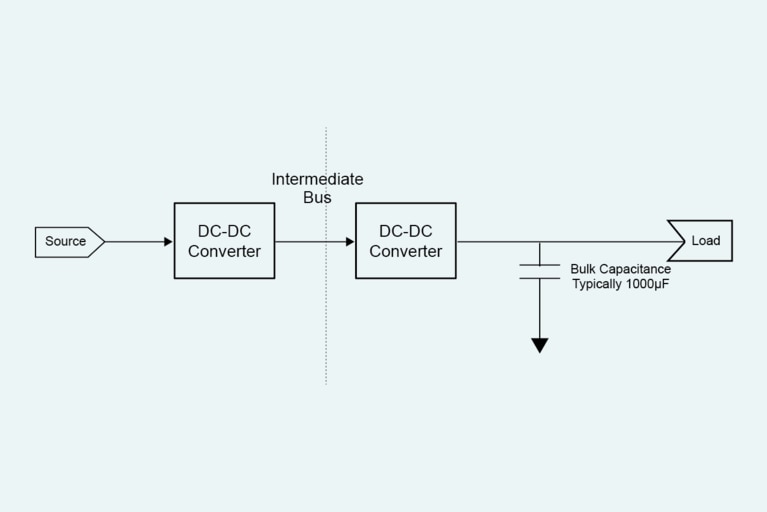

Consider an example where a 48V rail needs to be stepped down to 1.5V. Using a conventional approach, a DC-DC converter steps-down the voltage to an intermediate bus – typically at 12V – and then a second DC-DC converter delivers the 1.5V supply to the load (Figure 1). A large external bypass capacitor is needed at the PoL, particularly where there can be a rapid change in the current demanded by the load. If there is a transient change in the load current, the DC-DC converters will be unable to respond quickly enough, and so the energy required must be delivered from the capacitor.

Figure 1: Traditional two-stage power system.

This large bulk capacitance takes up significant space and adds to the overall weight of the system. Once the requirement has been defined, selecting capacitors based on size and weight will have a minimal impact. To achieve the objective of significantly reducing size and weight, the capacitance required must be reduced dramatically.

The Factorized Power Architecture™ separates the voltage regulation from the transformation and isolation. The Pre-Regulator Module (PRM™) generates a regulated factorized bus, and the Voltage Transformation Module (VTM™) steps down the voltage and provides isolation.

By separating the regulation from the isolation and transformation, FPA allows the development of highly optimized power components. VTMs can deliver large step-down ratios without impacting overall efficiency, allowing for a direct conversion from 48V to the PoL voltage. Eliminating the intermediate bus simplifies the system design and improves efficiency.

PRMs and VTMs are very compact power components, and switching to FPA can deliver significant improvement in the size and weight of the converters. The biggest impact, however, is typically the ability to eliminate the need for large bulk capacitance.

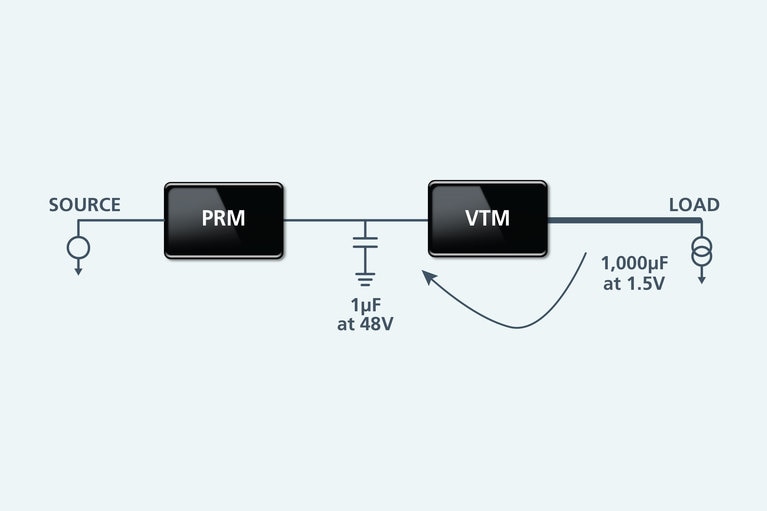

VTMs have a high switching frequency, bi-directional power processing and low output inductance that produces an extremely high bandwidth: their response to load change is 20 times faster than the fastest competitive Brick DC-DC converter. This means that a VTM acts much like a transformer, even at frequencies approaching the converter’s bandwidth. At these frequencies the output “reflects” the input capacitance at the output, increased by the square of the turns ratio, eliminating the need to place the capacitance at the point-of-load. The bulk capacitance can be moved upstream to the input of the VTM, typically using low ESR/ESL ceramic capacitors (Figure 2).

Figure 2: Reduction of capacitance with Factorized Power Architecture image.

The energy stored in a capacitor is calculated as ½CV2. This means that the amount of capacitance required to store a given amount of energy decreases with the square of the voltage. So in the example above, where the capacitance is moved from the 1.5V rail at the point of load to the 48V bus at the input to the VTM, the reduction in required capacitance can be calculated as:

Capacitance at input to VTM = 1000μF • (1.5/48)2

= 1000μF • 0.00098

= 1μF

The power components used in a FPA system deliver high efficiency, low noise and operate at a high switching frequency. This enables size and weight reductions in EMI filtering and heat sinking, which can typically be reduced in size by 30%.

Vicor also offers power components such as the BCM® (Bus Converter Module), which provide a frontend for HVDC power systems. Using HVDC for power distribution increases efficiency and reduces the size of conductors required to distribute power. The BCM steps down a nominal 380V HVDC supply to 48V, connecting directly to the input of the PRM™, which simplifies the development of a complete HVDC power chain.

In this example, we have seen that FPA allows engineers to move capacitance from the point-of-load to the 48V factorized bus, reducing the required capacitance 1000-fold. In some applications where there are transient changes in the current demanded by the load, the elimination of bulk capacitance, coupled with the compact size of the Vicor Power Components and the efficiency of the single-stage step-down of the voltage, can result in power systems that are eight to ten times smaller and lighter than conventional solutions.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

ReVolt – Technical Q&A

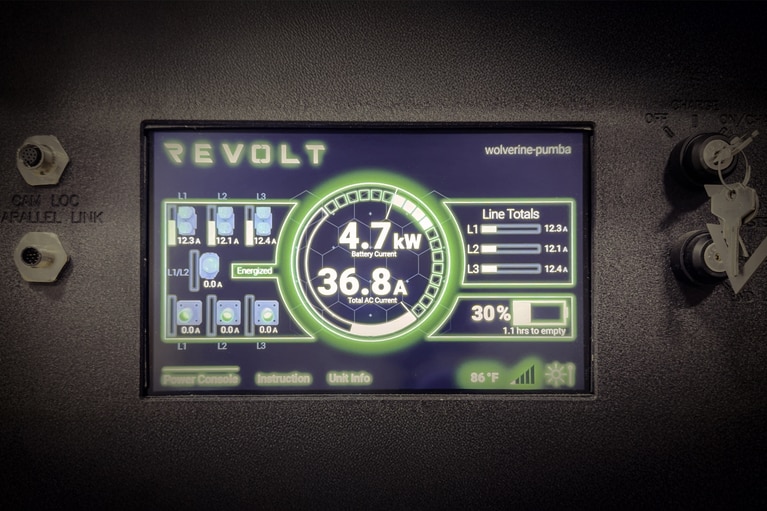

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity

Helping Hollywood fulfill its green ambitions

ReVolt is the cleaner, greener solution to the massive fossil fuel burning generators used on movie sets today. Learn how Vicor is helping ReVolt