電力供給ネットワークを刷新する 電圧変換比固定 DC-DC コンバータ

This white paper discusses the fixed ratio, DC DC converter and why designers should consider it an essential part of the power delivery architecture

We recently had a customer that had a variety of unique power system challenges that needed to be overcome. One of these challenges required configuring one of our many DC-DC DCM modules to provide a specific input and output voltage range. System requirements were:

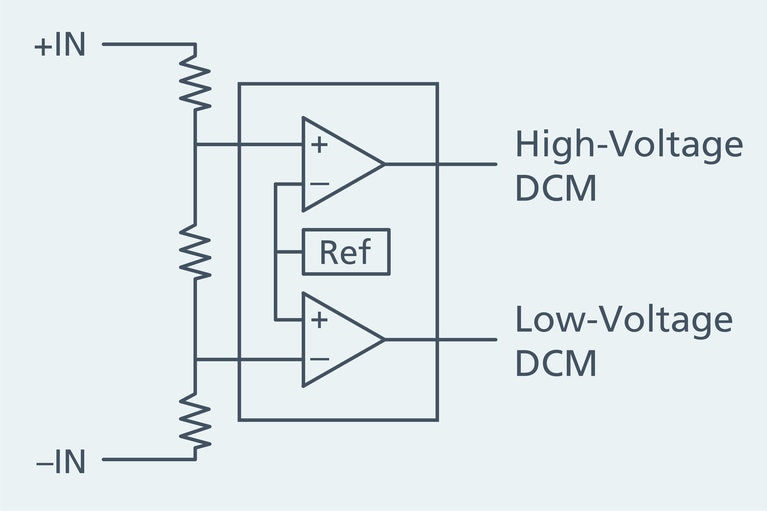

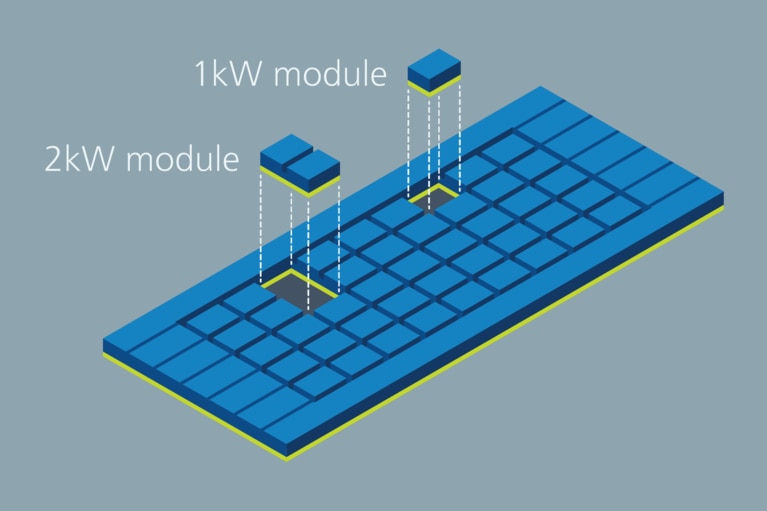

Using our Power Component Design Methodology we developed a solution using a mix of standard power components, plus specifically configured DCM DC-DC converter modules. Two DCM4623 converters were selected from our component library and configured to operate from a unique 210V nominal input voltage but with different output voltages.

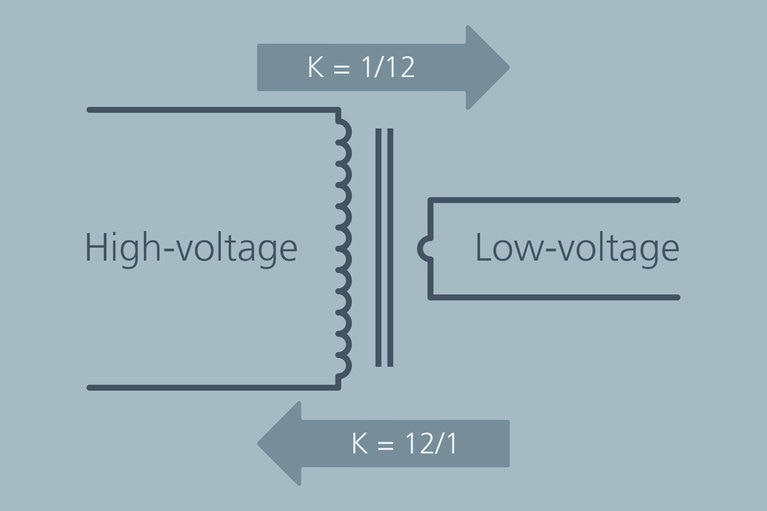

Eight of the first DCMs were configured in parallel to create a high power 3.2kW, isolated and regulated 22V output. This array fed the large bulk capacitor of 200mF. The second DCM was configured to create a 53V output, which was then fed into a pair of Bus Converter Modules (BCMs) to create an efficient, regulated 300W, 3.3V output.

The inherent benefits of the power components used in the design meant that the system had high power density, allowing it to be very small size and lightweight. As with all systems using the Power Component Design Methodology, the system was straightforward to implement, and the short-lead time, cost-effective configured DCM capability offered by Vicor avoided the delays and NRE typically associated with application-specific converters.

Additionally, the DCMs’ constant switching frequency simplified the filtering required to avoid interference affecting associated sensitive equipment.

By using the Power Component Design Methodology, the customer was able to create a highly flexible, efficient solution that met their performance and time to market objectives.

Related content

Product overview: DCM DC-DC converter modules

Product overview: BCM bus converter modules

電力供給ネットワークを刷新する 電圧変換比固定 DC-DC コンバータ

This white paper discusses the fixed ratio, DC DC converter and why designers should consider it an essential part of the power delivery architecture

複数のコンバータを使用した ワイド入力 DC-DC 電源ソリューション

通用解决方案通常可让情况简单化。但在选择超宽 DC-DC 电源时,这种方法无法获得最佳结果

高性能電源モジュールのパッケージング技術

パワーモジュールのパッケージングは、創業以来ビコールの独自の差別化要因となっています

Innovating power delivery networks

Vicor is innovating with power delivery networks. Improving end-system performance requires innovative power technologies