The future of long-haul trucking is accelerating autonomously on a freeway near you

Kodiak autonomous technology revolutionizes long-haul trucking. Learn more about Vicor power modules that drive mission critical ‘seeing’ sensors

Electric motorcycles are an important part of the solution to pollution and climate change as the world seeks alternatives to fossil fuels.

In the transportation sector, electric motorbikes (e-bikes) are quickly developing and creating market demand. Electric motors provide the propulsion for these two-wheeled vehicles, eliminating the demand for internal-combustion engines (ICE) that emit greenhouse gases. Zero tailpipe emissions are another way in which electric motorcycles help the environment. Electric motorcycles are an important part of the solution to pollution and climate change as the world seeks alternatives to fossil fuels.

One of the most innovative e-bike manufacturers is Lightning Motorcycles (Lightning), a company that produces advanced, high-performing electric motorcycles. In this article, CEO and co-founder Richard Hatfield explains how and why the company was founded, focusing on the challenges that power electronics engineers face when designing these types of vehicles.

Lightning was established in 2007 in San Carlos, California, to create two-wheeled e-bikes that deliver higher performance, higher efficiency and a better rider experience than ICE motorbikes.

“Sixteen years ago, we developed the first lithium-battery sport bike in the world,” Hatfield said. “For me, the performance and the experience of riding that bike were life-changing. I decided that electric motorcycle should be a product, and it should be something that had a very positive impact on the world.”

Several governments around the world have set very aggressive goals and created incentives to drive the demand for new electric motorcycles sold. They aim to increase e-bike sales by 30% in the coming years. Consequently, the real issue has been designing an electric motorcycle that equals or exceeds the performance of the best gas motorcycle.

This goal is more challenging than making an electric vehicle, as the space constraints on a motorcycle are very limiting. Until Lightning started driving this engineering challenge, the performance of electric motorcycles in general was much lower than the performance of gas motorcycles. Additionally, the price of electric motorcycles was much higher.

Lightning presently holds the land speed record for electric motorcycles, surpassing 215 mph. The 35-year–old speed record was shattered at the Bonneville Salt Flats, where an electric motorcycle accelerated to 215.962 mph, surpassing the previous record of 211.7 mph set at the El Mirage dry lakebed.

As Hatfield said, Lightning’s top-spec motorbike (Figure 1) has a highway range, riding at 70mph for 170 miles. It features 180 horsepower at the rear wheel and more than 100 foot-pounds of torque at the motor shaft. Additionally, the recharge time from up to 80% with the 24kWh Lightning-Fast Charging System is about 10 minutes, while the performance is equal to or greater than that of many 1,000cc gas motorbikes. The energy is provided by a 380V 20kWh battery pack featuring 293 miles per charge for combined city/highway.

Figure 1: The Strike R e-bike (Source: Lightning Motorcycles).

The increasing complexity of Lightning’s motorbikes has necessitated a weight reduction without a commensurate increase in power for the integrated electronics. Managing electrical noise in a compact and lightweight vehicle is a perpetual challenge.

Lightning opted to utilize Vicor DCM4623 DC-DC converters to power its 12V control electronics: lighting system, cockpit instrumentation and sensors. Subsequently, Lightning adopted this converter across all of its products. The selection of power modules manufactured by Vicor was predicated on their superior thermal management, high power density and low background-noise levels. Presently, the most advanced iterations of Lightning’s electric motorcycles boast a range exceeding 170 miles and a rapid recharging time of 10 minutes to 80%.

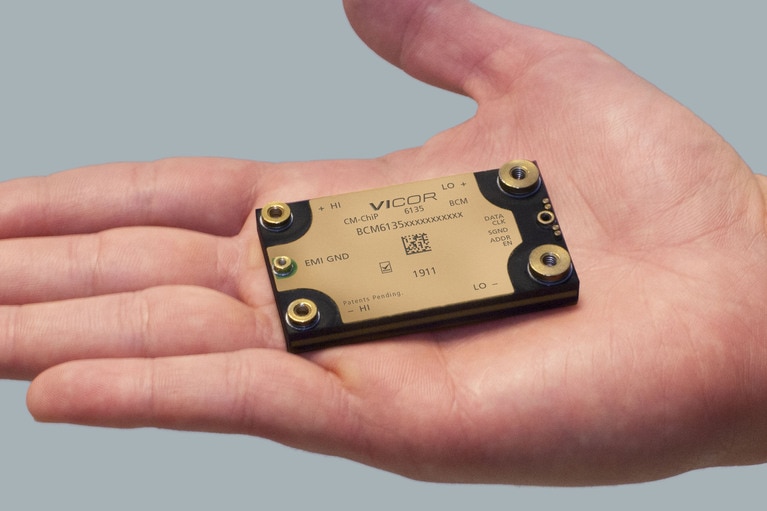

The 12V sensors, illumination system and instrumentation on the Lightning are all supplied with power by a Vicor DCM4623 DC-DC converter (Figure 2). This converter is an economical and lightweight solution that also possesses substantial power. Lightning asserts that the selection of Vicor DCM™ line of DC-DC converters was predicated on their superior thermal management, low noise, high power density and high dependability.

The DCM4623 module provides adaptable thermal management alternatives enhanced by the thermal and density advantages of Vicor ChiP™ packaging technology, in addition to exceptionally low thermal impedance on the top and bottom sides. Power components based on thermally efficient ChiP allow customers to implement cost-effective power system solutions rapidly and predictably with system size, weight and efficiency attributes that were previously unattainable.

“We rely on Vicor DCM family of DC-DC converters, as they have high power density, high efficiency and a small footprint,” Hatfield said. The available space is critical for an electric motorcycle. On high-performance electric motorcycles, in particular, weight is the enemy of performance motorcycles.

“We very much appreciate the power density and reliability of the Vicor power converters, as they are helping us to drive the control electronics, the VCU, the motor ECU and the battery management system,” Hatfield said.

Figure 2: Lightning uses the Vicor DCM4623 DC-DC converter, a power-dense, lightweight and cost-effective power-converter solution.

As Hatfield points out, in a 150kW electric motorcycle, there’s a lot of electrical magnetic noise throughout the system, from the inverter to the cabling to the battery pack itself. Noise is a major challenge when operating the bike and charging it at high-power levels.

Whenever a vehicle generates a lot of power, a significant percentage of that will be converted into heat, creating potential thermal issues. Because liquid cooling involves additional weight, Lightning decided to address this challenge using a hybrid method (liquid and air) to cool the battery pack.

“The environment that electric motorcycles are operated in is very challenging,” Hatfield said. “It includes issues like moisture, rain, vibration, electrical noise and thermal issues.”

A typical motorcycle is less aerodynamic than a typical car, even though it is smaller. For this reason, Lightning has done a lot of computational-fluid–dynamics modeling and wind-tunnel testing.

“This is one of the reasons why we are achieving high-speed records,” Hatfield said. “Everything we learn about making a motorbike more efficient means we can use a smaller battery pack and a more affordable drive system providing the same performance and longer range.

“I see a time in the future where petrol motorbikes will be collected as great historical pieces, whereas the typical motorbike will be electric,” he concluded. “I don’t think that future is that far away.”

This article was originally published by Power Electronics News.

Automotive solutions: Solving 400V/800V EV fast-charging compatibility

Podcast: The future of long-haul trucking is accelerating autonomously on a freeway near you

White paper: High-bandwidth power modules quell the disruption of high-voltage line ripple rejection

eBook: Innovative power solutions enabling the electrification transformation

The future of long-haul trucking is accelerating autonomously on a freeway near you

Kodiak autonomous technology revolutionizes long-haul trucking. Learn more about Vicor power modules that drive mission critical ‘seeing’ sensors

Power modules boost innovation

Vicor power modules are solving today’s toughest power challenges with innovative topologies, architectures and packaging

人とくるまのテクノロジー展 2024 ONLINE STAGE 1

電動車の400Vと800Vの高効率電圧変換について、自動車メーカ各社の方式と合わせて紹介

International Conference EEHE 2024, Germany

Vicor presented a solution for mitigating inverter ripple currents and voltage in electric vehicles at EEHE conference