面向未来的汽车高压转 SELV 方案

传统的 12V 架构已无法承受车载电子负载的不断增加。了解电源模块如何加速向 48V 的转型

随着电动汽车(EV)向更高性能、更轻重量和更佳驾乘动态不断发展,电源系统设计需要不断突破新的极限。

《Electronic Specifier》记者 Paige West 与 Vicor 公司 Greg Green 的问答

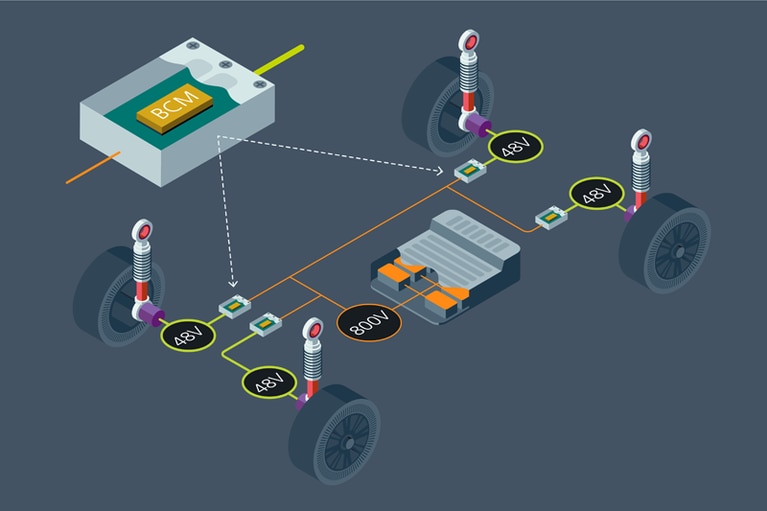

主动悬架是一个快速创新的领域,已成为现代电动汽车平台确保乘客舒适度和道路操控性能的关键功能。汽车系统专业厂商宏发公司(Hongfa)已开发出目前市场上最小、最轻的主动悬架解决方案,这在很大程度上得益于与 Vicor 的合作。

《Electronic Specifier》杂志就此与 Vicor 汽车营销总监 Greg Green 进行了深入探讨。

问:Vicor 是如何参与宏发新型主动悬架系统开发的?这次合作是如何开始的?

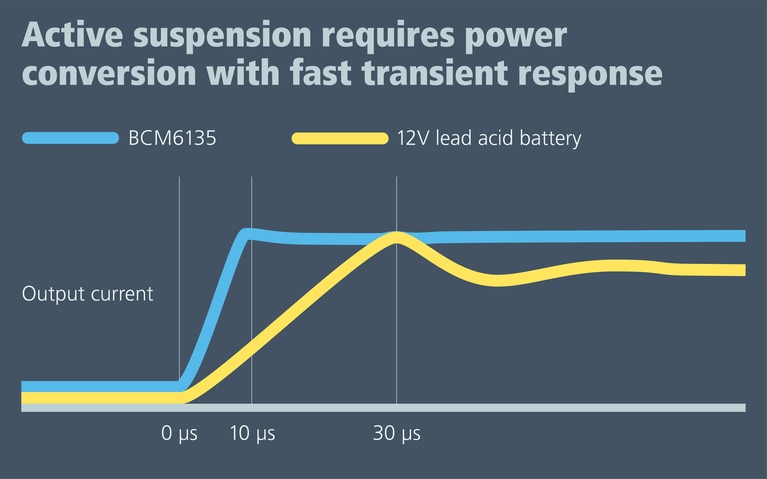

答:Vicor 与宏发的合作始于一家汽车制造商的需求——他们需要一个紧凑但功能强大的 DC-DC 转换器来驱动主动悬架电源系统。Vicor 的技术提供了所需的解决方案,缩小了 DC-DC 转换器的尺寸,同时减轻了宏发的系统设计工作量。Vicor 的电源模块还提供了最快的瞬态响应速度,这对于优化能量回收能力至关重要。

宏发公司结合 48V 系统和 Vicor 电源模块,成功设计出了目前市场上最小、最轻的主动悬架系统。Vicor 的正弦幅度转换模块能够支持需要在电池与悬架执行器之间实现双向电流流动的主动悬架电源系统。

问:BCM6135 被誉为拥有业界最快的功率转换瞬态响应。这一特性背后的技术创新是什么?

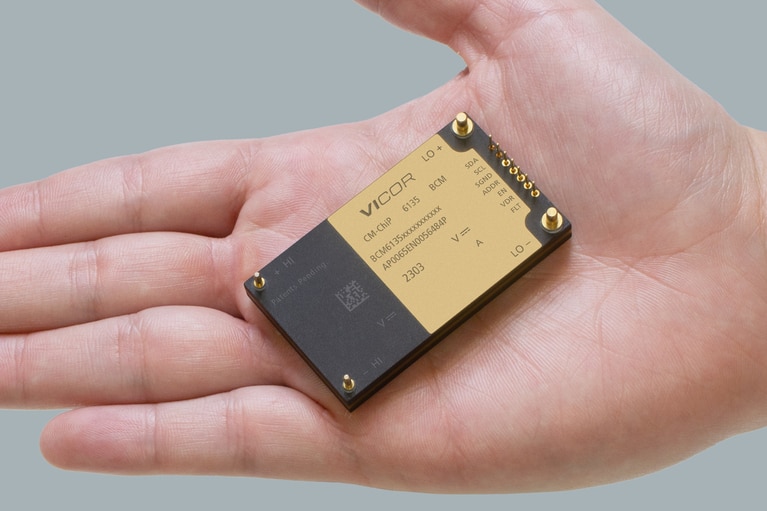

答:Vicor 模块采用正弦幅度转换(SAC™)技术,这是一种能够在高低电压间实现零电压/零电流切换的拓扑结构。Vicor 运用专有的控制器和组件来驱动这项技术,使完整的 DC-DC 转换器能够集成在极其紧凑的封装中(仅 0.01 升)。其瞬态响应速度高达每秒 800 万安培,是汽车行业的最快水平。

BCM® 技术的独特优势在于,SAC 拓扑可在极高频率(超过 1.4MHz)下运行,并具备每秒 800 万安培的压摆率,为客户带来了以往难以实现的能力。

问:在汽车应用中,BCM6135 的固定比率双向设计与传统 DC-DC 转换器拓扑结构有何不同?

答:BCM 技术的独特优势在于,SAC 拓扑可在极高频率(超过 1.4MHz)下运行,压摆率为每秒 800 万安培,这为客户带来了以往难以实现的能力。产品的双向特性是竞争对手难以匹敌的另一大优势。得益于 SAC 拓扑结构,BCM6135 无论是在升压还是降压模式下都能处理相同的功率。这些特性使 BCM 在主动悬架等高难度应用中表现出色,远超其他 DC-DC 技术。

BCM6135 的双向特性是竞争对手无法匹敌的另一优势。得益于 SAC 拓扑结构,BCM6135 无论是在升压还是降压模式下都能处理相同的功率。

问:最终系统的尺寸几乎是其最接近的竞争对手的一半。Vicor 的封装和热设计创新是如何助力实现如此紧凑外形的?

答:Vicor 的 BCM 模块是一个完整的 2.5kW DC-DC 转换器,封装体积仅为 0.01 升(61 x 35 x 5.4 毫米),省去了通常使用的许多大型分立组件。宏发这样的系统组装商只需封装车辆连接器、一些基本的 EMI 滤波器组和 PMBus® 接口。BCM 可采用主动或被动冷却方式,只需配备冷却结构和系统外壳。

问:平面封装和液冷技术在实现高电流传输并最小化热损耗方面发挥了什么作用?

答:平面封装和 BCM 的整体设计使模块的热阻系数达到 1.4°C/W,与许多标准封装的 MOSFET 相当。将 BCM 集成到液冷设计中可以最大化功率输出,因为 SAC 拓扑结构在峰值功率时受到热限制。

问:许多早期主动悬架设计都受到 12V 系统局限性的制约。BCM6135 是如何解决这些历史遗留问题的?

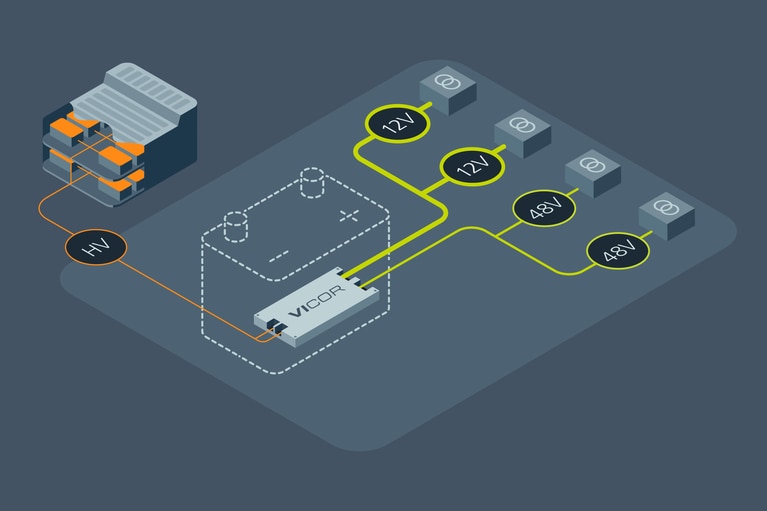

答:BCM6135 是一款固定比率转换器,能够高效地将高压(HV)转换为 48V。主动悬架供电网络(PDN)需要 48V 母线和电源模块才能实现最佳性能。

低压供电系统需要使用更大且效率更低的执行器来驱动主动悬架系统。几十年前推出的一些早期系统需要数百磅重的执行器电机和电池来承受主动悬架系统产生的巨大电流和功率波动。与老一代产品相比,48V 执行器体积缩小超过 50%,而且功能更强大。

BCM6135 凭借其高压摆率和双向功率处理能力,能够消除系统中的电池。采用 BCM6135 为核心的主动悬架系统可以减重 100 多磅。

问:Vicor 的 800V-48V 解决方案为新兴的 48V 区域架构和电动汽车动力系统带来了哪些优势?

答:Vicor BCM6135 为电动汽车的 DC-DC 转换器和低压网络带来了多项改进。首先,使用 BCM6135 可将主 DC-DC 转换器的尺寸减少高达 50%,重量减轻 50%。其次,其功率开关功能允许删除 48V 电池,因为 BCM6135 从高压电池向负载供电的速度比从 48V 电池取电更快。最后,DC-DC 转换系统体积足够小巧,可直接安装在高压电池外壳内,从而消除额外的冷却管线和高压电缆。

问:您认为在未来几年,固定比率高压 DC-DC 模块是否会在主流车辆电子系统中得到更广泛的应用?

答:会的,我们预计我们的技术会在未来几年有更广泛的应用。应用增长的动力在于 Vicor 技术能够解决汽车制造商在打造高效、省空间且轻量化车辆时面临的棘手电源问题。Vicor 的 DC-DC 模块化转换器是市场上功率密度最高的产品,可以并联使用——这使得扩展功率变得非常简单,能够适应车队的各种功率需求。

问:Vicor 如何定位其电源模块,以满足电动汽车和先进出行领域对紧凑、高效设计日益增长的需求?

答:我们与一级供应商伙伴和汽车制造商工程团队合作,寻找能够用 BCM6135 解决的棘手问题。我们与这些公司携手合作,展示我们的技术如何实现最优雅、最有效的功率转换解决方案,并减少体积和重量。我们专注于最适合使用我们技术的问题,帮助客户获得成功。

本文最初由 Electronic Specifier 发布。

Greg Green 现任 Vicor 公司汽车客户项目总监。他在汽车行业拥有超过 33 年的丰富经验,涉及 OEM 厂商和一级供应商的制造、设计工程和产品线管理。Greg 丰富的汽车产业经验包括制造、产品开发和业务开发等。Greg 先后毕业于密歇根大学和凯特林大学,分别获航空航天工程学士学位和制造管理硕士学位。

Greg Green,汽车营销市场经理

面向未来的汽车高压转 SELV 方案

传统的 12V 架构已无法承受车载电子负载的不断增加。了解电源模块如何加速向 48V 的转型

电源模块助力简化电动汽车的爬电距离与电气间隙设计

包覆成型是解决 48V 汽车电源系统中电弧问题的关键

48 伏脉冲功率技术可在 60 秒内为汽车玻璃除霜

Betterfrost 实现在不到 60 秒内使用适当的脉冲功率完成汽车玻璃除霜。了解更多关于 Vicor 电源模块如何实现 48V 创新的详情

双向供电与快速瞬态响应能力赋能可扩展的主动悬架系统

正弦振幅转换器™(SAC™)模块凭借其独特的双向供电功能与瞬态响应速度组合,为主动悬架系统开辟了全新可能性