優化 DC-DC 轉換器穩定性:源阻抗效應的 AC 與瞬態模擬分析

探討如何通過頻域 AC 小訊號分析和時域瞬態分析來優化 DC‑DC 轉換器的穩定性

The benefits of moving to 48V power delivery networks are well documented. However, the technical challenges are not as evident. As development engineers embark on their first 48V designs, questions naturally arise. To help you better prepare for your 48V migration consider the following 15 challenges.

An important element of the high voltage (HV) to 48V power delivery network (PDN) design is providing isolation that complies with regulatory safety standards.

Regulation often is not required in the first stage of conversion, which allows the use of advanced topologies, specifically fixed-ratio Sine Amplitude Conversion (SAC™). Fixed-ratio SAC bus converters use a resonant circuit architecture that minimizes transformer leakage inductance, maximizing conversion efficiency. Additionally, the use of zero-voltage and zero-current soft switching minimizes switching-dependent switching losses, further enhancing efficiency. SAC bus converters provide strong (typically more than 4,000V) galvanic isolation, bidirectional operation and very high transient response. Fixed-ratio 800V and 400V SAC bus converters are available in small modular form factors, offering full compliance to creepage and clearance standards.

As power systems become more compact, it becomes increasingly important to protect loads that are sensitive to noise by using converter topologies that possess low inherent switching noise. Converters that use a high switching frequency shift the conversion noise byproducts into higher frequency bands where they can be more easily filtered, causing less disruption to sensitive loads. Soft MOSFET switching methods such as zero-voltage switching (ZVS) and zero-current switching (ZCS) emit less EMI noise and thus minimize disturbances that might otherwise affect noise-sensitive loads.

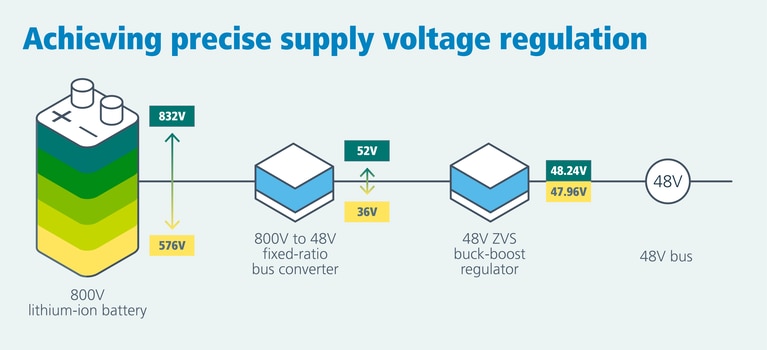

Figure 1: The output voltage of an 800V battery might range from 576 to 832V, due to state of charge, age, temperature and other factors. A high-efficiency fixed-ratio bus converter outputs a nominal 48V but reflects this wide range. A second-stage ZVS buck-boost converter regulates this range to a precise 48V for use downstream.

Some subsystems and peripherals have migrated to native 48V operation, particularly those with power requirements higher than what 12V supplies can reasonably provide. While some of these subsystems do not require a tightly regulated 48V rail, others do need precise supply voltage regulation.

The need for a regulated 48V bus can arise when converting high-voltage DC source to 48V with an isolating fixed-ratio bus converter, which typically does not have a regulated output. If the bus converter is being fed by a 400V or 800V battery, the bus converter’s output can vary widely depending on the battery state of charge, as well as ambient temperature, battery age and the specific load characteristics. For example, the output voltage of an 800V battery might range from 576 to 832V. With a K = 1/16 bus converter, this input voltage range corresponds to an output voltage range of 36 – 52V.

In this case, the use of a ZVS buck-boost DC-DC converter stage can be helpful. For example, a typical 800W ZVS buck-boost converter might offer a wide input voltage range (such as 38 – 60V, 48V nominal), and a nominal 48V output trimmable from 30 to 54V. The output voltage load regulation of a ZVS buck-boost converter of this class might be 0.3% and the typical conversion efficiency might be 97.7% at full load. This level of performance is likely to meet the requirements of the most demanding 48V loads.

Where to regulate the 48V rail depends on the system design. If there are no 48V “native” subsystems, and all the loads operate at 12V, 5V, 3.3V or sub-1V, there is no practical need to regulate the 48V power bus. In this case, the regulation can occur in the “bridging” conversion to 12V or in the point-of-load conversion from 48V to low voltage using a buck regulator.

For 48V to 12V bridging applications, a regulated non-isolated DC-DC converter is appropriate, with the continuous and peak output power scaled to the load requirements. The input voltage range should be wide enough to support any variability on the 48V bus. The 12V regulation tolerance depends on system requirements; ZVS buck regulators might have a typical output voltage load regulation limit of 0.1%.

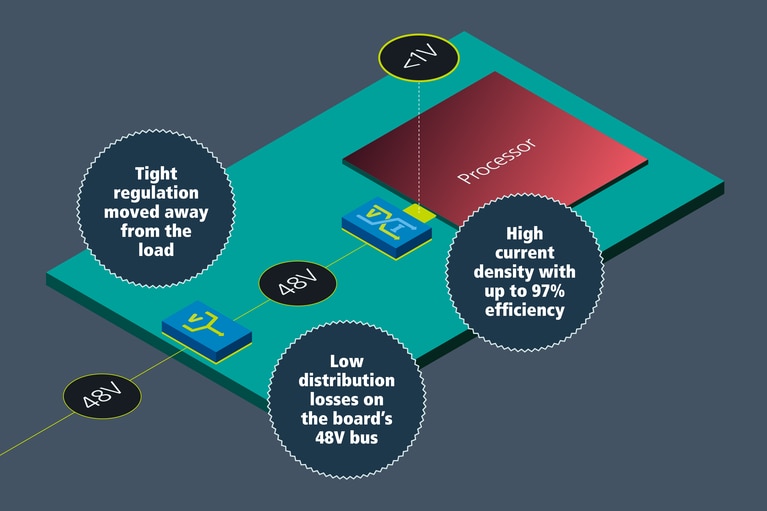

For 5V, 3.3V, 1.8V and sub-1V regulated point-of-load processor power applications, it can be advantageous to split the regulation function and the current multiplication function. This functional partitioning is referred to as factorized power architecture (FPA™). FPA defines a precise regulation stage followed by a voltage transformation stage or a current multiplier stage that delivers high current levels at precisely regulated supply voltages. The current multiplier transformation “K factor” determines the output voltage, for example K = 1/48 delivers 1V to the load. The level of current provided by the 48V source is correspondingly multiplied by 48. Factorized power architecture allows the regulator stage and the current multiplier stage to be physically separated, to reduce component “congestion” or crowding around the processor.

A significant challenge with powering high-current loads is minimizing conduction losses in the printed circuit board copper traces or tracks. One approach to powering high-current, low-voltage loads (such as AI processors) is factorized power architecture (FPA™). In this architecture, a high-power regulator stage converts 54V to 48V with high efficiency. This regulator stage can be placed at the periphery of the accelerator PCB, to avoid contention with other functions, including memory and high-speed serial I/O. The regulator stage tightly regulates the 48V supply, making further downstream regulation unnecessary.

Figure 2: In a factorized power architecture, the first-stage regulator is relatively remote from

the processor, freeing board area for other critical functions. The second stage current multiplier

uses high efficiency fixed-ratio conversion to transform 48V to 1V (or other low voltages) and

can be placed either laterally or vertically beneath the processor to limit PCB conduction losses.

Use of 48V as the intermediate bus voltage minimizes conduction losses. A voltage transformation stage or current multiplication stage is placed lateral to the processor (lateral power delivery) or ideally vertically beneath the processor (vertical power delivery). The placement minimizes the copper PCB trace length between the current multiplier and the processor power and ground connections to reduce the PCB impedance and associated resistive thermal losses. The voltage transformation and current multiplier blocks are fixed-ratio converters that can deliver hundreds of amps at sub-1V levels. The FPA approach can meet the power delivery needs of the most advanced CPUs, GPUs and network processors.

High-voltage (800V and 400V) power delivery systems should provide thousands of volts of galvanic isolation. Ideally, these systems should also provide up to 100MΩ of insulation resistance, and sufficient creepage and clearance provisions to meet industry safety requirements, such as IEC 60664-1. Discrete designs based on standard switching topologies are limited in their ability to achieve high isolation ratings because of parasitic capacitance between components, inability to design with adequate creepage and clearance distances, and the difficulty of synchronizing high-speed switching while maintaining dielectric integrity across isolation barriers.

DC-DC converters based on SAC topologies can achieve extremely high voltage isolation ratings thanks to zero-voltage and zero-current switching. These soft-switching techniques reduce EMI and minimize voltage stress across the isolation barrier, which enables the use of compact magnetic structures without compromising insulation performance. As a result, SAC topology DC-DC converters can integrate high-isolation transformers and maintain efficiency even in dense, high-voltage environments where discrete component solutions often fail.

When high-voltage components are packed tightly on a PCB, the risk for electrical arcing (clearance) and electrical tracking (creepage) increases. Note that arcing and tracking are impacted by working voltage, pollution level, altitude, moisture and humidity, insulation material, and transient voltages. While potting approaches can help mitigate risk, fully-molded packaging is a far more effective solution. The use of a power-dense integrated solution is a better choice because the components required to implement the power system are encapsulated within the epoxy-molded package, lowering or eliminating the risk of arcing and tracking. It is important that the power solution supplier tests for creepage and clearance compliance with standards such as IEC 60664-1 and 62368-1.

Today the 48V component and associated ecosystem is not as well developed as the 12V component ecosystem, which has developed over many decades. In many cases, 12V components and subsystems are fully cost-optimized with many sources of the same function competing on price. A reasonable system architecture choice may be to retain 12V subsystems when they can meet system performance goals and to choose 48V subsystems where the higher voltage provides key performance advantages. Because of the relative scarcity of 48V power components for discrete power supply implementation, modular 48V DC-DC converters can be an attractive option. The use of modular power converters dramatically reduces product development, test time, expert engineering resources and expense. They also enable rapid prototyping and reduce the burden of bill-of-materials procurement and component lifecycle management.

Where combining the two approaches is desirable, adopt a 48-to-12V bridging strategy. If the 48V bus is already regulated, a 48V to 12V fixed-ratio non-isolated bidirectional bus converter is ideal, as the conversion efficiency is typically extremely high. If the 48V bus is not regulated, a non-isolated zero-voltage switching (ZVS) buck DC-DC converter can provide a 12V regulated output from a 48V unregulated source.

Many real-world systems exhibit periods during which the power demand peaks on an intermittent basis. But it can be a needless expense to design a power system specified for intermittent peak power (load step) demands. Point-of-load capacitors are typically used to supply energy to accommodate peak power spikes. Often power systems offer a short duration (for example 20ms) peak power capacity that can reach 50% higher than the continuous output power specification.

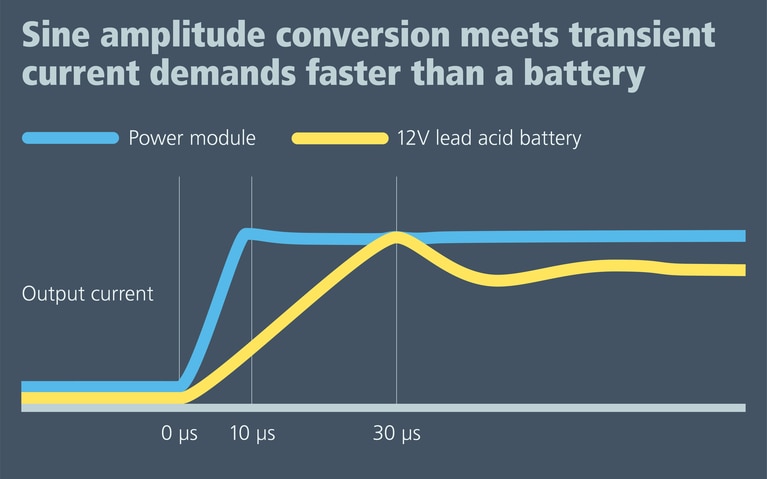

Fixed-ratio SAC bus converters can deliver a rapid instantaneous response (millions of amps per second) which can reduce the need to over-specify the output power rating to handle peak power demands. These converters also exhibit a unique capacitive multiplication attribute: input capacitance is multiplied by the square of the K factor, appearing as an effective output capacitance. This characteristic reduces the amount of capacitance otherwise needed to meet peak load step demands.

DC-DC converter efficiency is related to conversion topology and partitioning, MOSFET switching frequency and other factors. A converter topology that uses zero-voltage switching and zero-current switching can offer higher efficiency than alternative topologies. Factorized power architecture, with a high-efficiency regulator first stage, and a voltage transformation / current multiplier second stage offers exceptional efficiency, by virtue of the fixed-ratio current multiplier, which acts as an ideal DC-DC transformer. A high MOSFET switching frequency minimizes circuit parasitics and helps to increase conversion efficiency. Advanced packaging with low thermal resistance and coplanar top and bottom surfaces for heat sinks and coldplates increases reliability (i.e., higher MTTF) by reducing the maximum internal temperature of the power module.

Clearly, the most effective way to keep a compact PDN cool is with the use of high-efficiency DC-DC converters. Beyond that, compact power systems must deal not only with the heat dissipation from the individual components and modules, but also with the mutual heating of the closely spaced components and modules. Generally speaking, either air-cooled or liquid-cooled hardware must be used with high power (above about 1kW) PNDs. The higher the power density (W/in3) of the power system, the more important it is to use an active (air- or liquid-based) cooling system to ensure high reliability. Power system components with high conversion efficiency and low thermal impedance packaging are essential to a more passive approach to cooling, especially for compact PDNs.

Some electronic subsystems, such as microprocessors, memories and data converters must be provided with stable supply rails to avoid permanent internal device damage (advanced semiconductor process transistors are sensitive to supply voltage). The purpose of power regulation stages is providing, for example, a precisely regulated 48V output (~0.2% typical output voltage load regulation) from a wideranging input (40 – 60V is typical). This allows the first-stage regulator to work with a battery-fed bus converter where the nominal 400V battery might range from 340 to 460V depending on its state of charge, temperature and age. A K = 1/8 fixed-ratio stage converts this range to 42.5 – 57.5V, which falls within the input range of the regulator. Depending on the use case, a wide input range regulator is essential for functional compatibility.

There are various electronic and electro-mechanical systems that are characterized by highly transient or instantaneous demand for power. For example, 12V and 48V batteries in automobiles serve transient current demands from different subsystems (such as from an HVAC motor) within the car. Another example are the current transients that result from changes in the algorithmic loading of a multicore data center AI processor. In both cases, the best PDN solution to handle these transients are fixed-ratio converters using the Sine Amplitude Conversion (SAC™) topology. This type of converter utilizes a high switching frequency, allowing energy to be transferred to the output more frequently, assisting with transient current demand events. They are also characterized by low output AC impedance, which helps to keep the output voltage stable during transient events. Converters leveraging SAC also act as capacitance multipliers, where the input capacitance is multiplied by the square of the transformation ratio (K) and effectively appears on the output. This capacitance multiplication effect improves the overall transient performance of the PDN.

Figure 3: High switching frequency resonant Sine Amplitude Converters use soft switching (ZVS and ZCS). They are characterized by high control bandwidth, low AC output impedance and input capacitance multiplication, which all contribute to extremely high transient response, exceeding that of lead acid batteries.

Most systems will include 12V loads, for example 12VDC fans. These 12V subsystems are often cost optimized over many years of production and may not be economically attractive to replace with 48V alternatives. For these subsystems, a 48V to 12V DC-DC converter would be ideal when a regulated supply rail is required, and a 48V to 12V non-isolated bus converter would be ideal when a nonregulated supply rail is sufficient. The non-isolated bus converter solution can provide a regulated output to the 12V subsystem if an upstream 48V DC-DC converter provides regulation.

It is common for the power demands of various electronic systems to increase over time. For example, in computer systems, additional memory or network hardware might be added. Ideally, the ability to scale up the power delivery network capacity without a major system redesign is advantageous. This takes some advanced planning but can be accomplished.

Some modular DC-DC converters support array operation in which multiple devices operate in parallel to double or quadruple the output power. Ideally, there is a simple wire interconnect current sharing scheme to form this power array. The advantage of this approach is that a board can be laid out for two or four parallel devices, with only one populated initially. Then, if the power requirements of the system increase over time, one to three (or more) devices can be added and a few jumpers connected, enabling the power system to scale up to meet new system power requirements.

Straightforward power delivery scaling supports the fast-turn evaluation and prototyping of different design options and expands the possibility of design reuse for systems with different power requirements.

Modular power solutions are far easier to prototype with than discretely implemented alternatives. They are compact, have relatively few I/O connections, and require minimal external components. Importantly, they are pre-tested and pre-certified to industry and regulatory standards. When time-to-market is a critical project objective, power modules offer an attractive value proposition.

The first widespread adoption of 48V system power can be traced back more than 100 years, when the nascent telephone industry recognized the efficiency and transmission distance benefits. More recently, the Open Compute Project has advocated for 48V power deliver within data center racks. Some electric vehicles are now employing 48V system power.

The pace of this generational change from 12V PDNs to 48V PDNs is now accelerating. It’s a question of when rather than if systems will migrate to 48V. The pressure from automotive electrification, the extreme pace of artificial intelligence computing, and the emergence of high-power industrial applications are converging on 48V power delivery networks. While power engineers have decades of experience and confidence with 12V PDNs, questions loom for design teams when migrating to higher capacity 48V PDNs. Discrete systems have been effective with 12V power designs for decades, but when set against evolving power delivery challenges, they can fall short. In many cases ongoing industry innovation – including architectures, topologies and packaging – will ease the implementation of next generation 48V challenges. This innovation will intensify the migration to 48V and help deliver scalable, high-density, future-proofed PDNs.

優化 DC-DC 轉換器穩定性:源阻抗效應的 AC 與瞬態模擬分析

探討如何通過頻域 AC 小訊號分析和時域瞬態分析來優化 DC‑DC 轉換器的穩定性

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

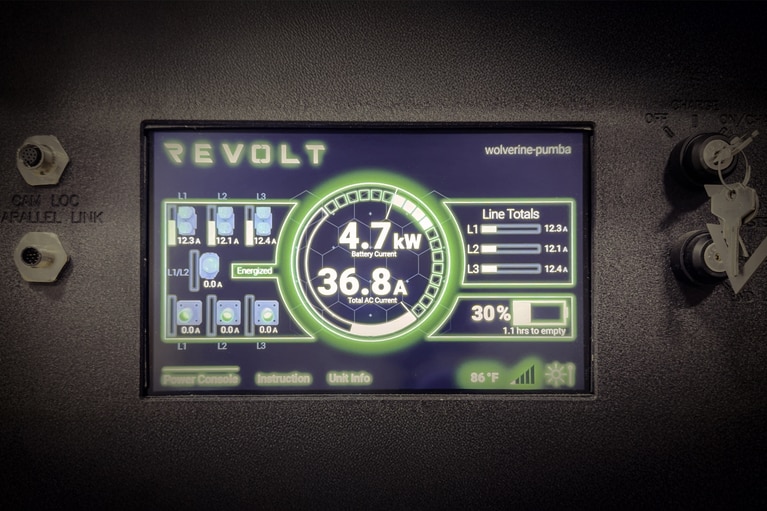

ReVolt – 技術問答

ReVolt 正在解决好莱坞片場的排放問題,下一步將把可擕式 DC 電源應用於建築工地、應急回應事件等領域

ReVolt 如何利用 Vicor 技術實現電影拍攝的碳中和

Vicor 電源轉換器提供清潔、可移動的不間斷電源