15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

需要考慮的關鍵問題:我的電路板有多少空間? 我需要哪些功能? 在我的設計中,效率有多重要?確定了這些問題的答案之後,您就能更好地理解在選擇降壓穩壓器時需要關注的內容,明白哪些要素必不可少,哪些屬於錦上添花。

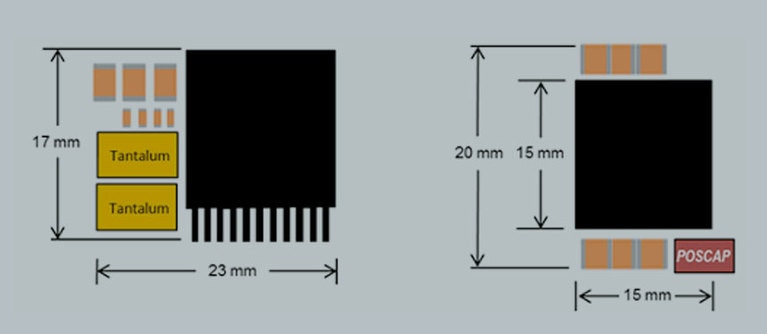

如果覺得這一點也不複雜,還望海涵,但有一點很重要,不能只關注封裝尺寸。 例如,下圖是目前兩家供應商提供的兩個模組。 封裝本身看起來很小,但一旦考慮輔助器件(主要是電容器),降壓穩壓應用的整體尺寸就會新增。

另一個可能導致整體解決方案尺寸變大的因素是設計中的佈局依賴。 類比地或電源輸出等的特定佈線要求,僅從封裝上就會顯著增加設計尺寸。

正如先前提到過的,高功率密度有散熱方面的考慮因素。 當你把電源設計得越小,散熱挑戰性也越大。 在考慮您真正需要什麼樣的穩壓器時,降低額定值是關鍵。

另一個考慮因素是電源輸出。 這不只是一個穩壓器的尺寸:您能减少電路板上穩壓器的數量嗎? 例如使用一個穩壓器取代兩個穩壓器,這將顯著减少電路板的空間,從而提高解決方案的密度。

就密度而言,更高頻率的工作非常理想。 一般沒有太多的選擇,或僅限於在降壓穩壓器工作的頻率範圍內選擇。 不過,在更高頻率下工作的降壓穩壓器將更小,而且還可縮小無源器件的尺寸。 更高頻率工作的負面特性是切換損耗。 頻率越高,效率越低。 這是我們在產品中通過使用 ZVS 拓撲來解决的問題之一,在常規降壓穩壓器中,這可能是必須的權衡。

當前降壓穩壓器的一些更基本的特性是軟啟動,或者跟踪……軟啟動允許控制輸出的上升過程,平穩達到最終電壓。 類似的功能是讓多個輸出相互跟踪,可以一對一,也可以按比例。 如果您在為微處理器供電,可能需要內核出現在外設等之前。軟啟動和/或跟踪對於確保平穩上電至關重要。

另一項特性是預偏置負載啟動; 這决定了降壓穩壓器在啟動時如何接入已存在的電源或母線電壓。它會拉低該母線電壓,還是能够從現有電壓提升至目標電壓? 預偏置負載啟動功能確保穩壓器啟動時母線電壓保持在所需的水准。

我認為效率對人們來說是顯而易見的,它是輸入到輸出的轉換。 關鍵要記住應用在整個工作條件下的效率。 通常在工作電流下有效率,也就是在高負載電流下有效率,然後處於待機或直接模式下也會有效率; 我們稱之為輕負載(或低負載)和高負載。 這兩個數位至關重要。 輕負載,也就是說,小於1安培對於滿足待機需求至關重要。 當然,在全面運行時,高負載會提供整體效率。

雖然器件效率是輸出至輸入的量測,但任何系統效率的計算都需要考慮線路損耗。 在考慮整體效率時,線路損耗可能會發揮非常重要的作用。 負載點轉換整個概念的一部分是通過在負載點附近佈置穩壓來降低線路損耗的理念。 這個理念的實現方法是:先將更高的電壓路由至更接近負載點的位置,然後降壓穩壓至更低的電壓。 牢記這些效能準則,您可以設計一款高效、有效的降壓穩壓器,匹配您的應用規模與需求。

在採訪的下一個環節,我們先著眼於降壓穩壓器的一些實施方法,然後討論零電壓切換(ZVS)架構的作用。

相關內容

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

面向未來的汽車高壓轉 SELV 方案

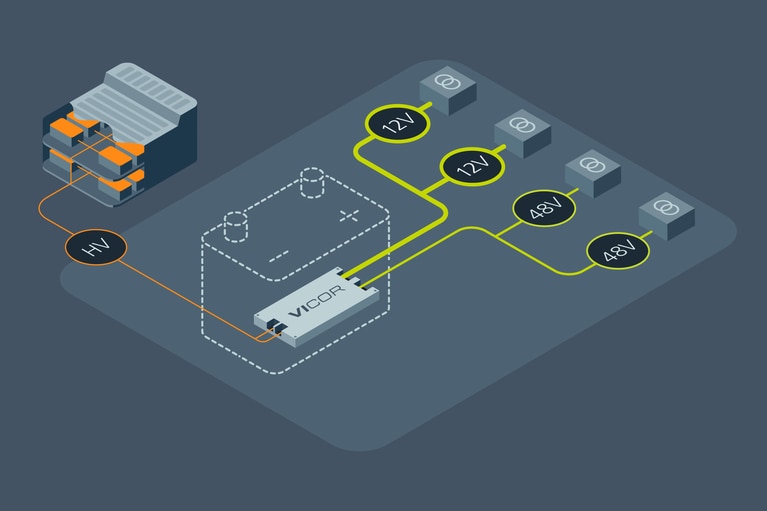

傳統的 12V 架構已無法承受車載電子負載的不斷增加。 瞭解電源模組如何加速向 48V 的轉型

電源模組助力簡化電動汽車的爬電距離與電氣間隙設計

包覆成型是解决 48V 汽車電源系統中電弧問題的關鍵

壓力下的動力:滿足軍事領域激增的電力需求

軍事電源系統設計者需要更多的效能(功率)和兼容性。 瞭解 Vicor SOSA 電源如何解决難題