ReVolt – Technical Q&A

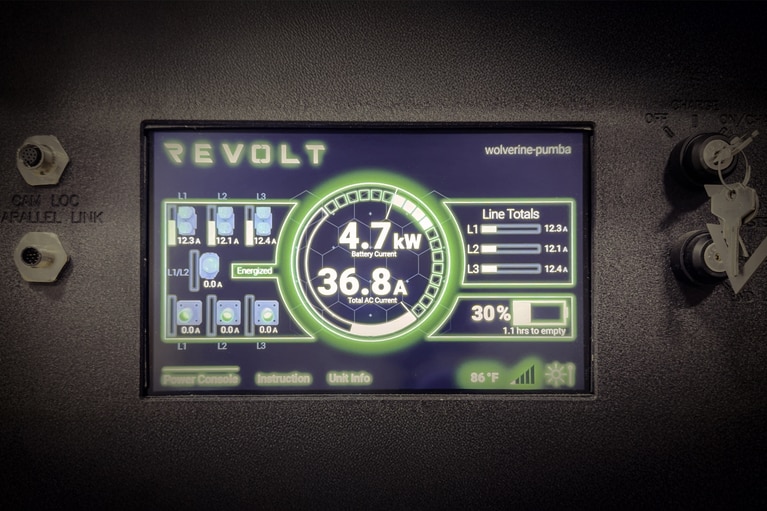

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

The next chapter in the war of current is about digital electricity. VoltServer's patented technology may revolutionize the way long distance wiring is done in the future – faster and more safely by today's standards.

VoltServer™ has developed a patented technology called Digital Electricity (DE). It enables either AC or DC electricity to be remotely distributed with the safety and economics of low voltage power systems.

Since the so-called “war of currents” — which, in the late 1880s, saw a strong competition between Thomas Edison and Nikola Tesla on proving which type of current (DC or AC) was more suitable for power transmission — there has not been much innovation around electricity.

Even though electricity plays an essential role in powering our world, the intrinsically dangerous nature of AC or DC power-transmission systems makes these systems expensive to deploy and maintain. To make power transmission safer and more efficient, VoltServer, a company with headquarters in East Greenwich, Rhode Island, has developed a patented technology called Digital Electricity (DE). It enables either AC or DC electricity to be remotely distributed with the safety and economics of low-voltage power systems.

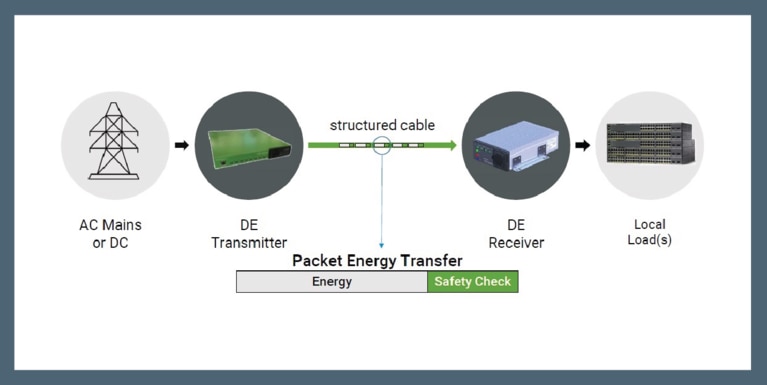

A simplified block diagram, explaining how Digital Electricity technology works, is shown in Figure 1. It first takes an analog electricity input (either AC from the mains or from a wall socket, or DC from a battery plant), and converts it into Digital Electricity in the DE power transmitter. Afterwards, the Digital Electricity is sent over copper cables to a DE power receiver, which converts the Digital Electricity back into either AC or DC, depending on which kind of load the user want to power at the remote end.

Figure 1: Digital Electricity block diagram.

A typical use case for this technology could be represented by wireless radios. When mobile service providers are deploying a 4G or 5G network, they want to deploy these radios into places that are optimal for RF coverage and capacity, which usually happens to be not where the outlets are located. The VoltServer™ technology allows providers to run power to the network radios using the same types of practices that they would use with a Power over Ethernet (PoE) connection.

“We have developed what we call a packet energy transfer,” said Luke Getto, director of product management at VoltServer. “To make it very simple to understand, think about a square wave with a 75% duty cycle. For three-quarters of the packet, we are sending power, while for one-quarter of the same packet, we are doing what we call our safety check. The safety check allows us to know if the packet has been properly sent and received.”

During the safety check, the system can determine if there has been a short-circuit, a resistive fault, an open circuit, and things like that. As long as no fault is detected, the system keeps sending the energy packets, while as soon an error is detected, transmission is stopped immediately. Packets are sent at a very high rate — roughly 500 packets per second. However, each single packet counts for a small quantity of energy. If a fault has been detected, the sending of packets is stopped, and the resulting energy dissipated into a fault is only about one joule. This allows VoltServer to use a much higher voltage that reduces the current and allows for small conductors (18–16AWG) to be used.

“The receivers are the devices that convert digital electricity back to AC or DC,” said Getto. “We are using the Vicor converters due to their very efficient DE-to-DC conversion. That allows our receivers to be smaller because the heat dissipation is much less. The efficiency of our receivers is close to 96% to 98%, and they are rated for 1,200W.”

Figure 2 shows the RX548 receiver, which has four Digital Electricity input channels and 48VDC output and is IP65-rated.

Figure 2: VoltServer RX548 receiver.

DE differs from PoE, which is limited to 90W, has a maximum range of 100 meters, and is run over very thin CAT6 cables. That results in a voltage of about 50V and a current of 2A. However, because the cables are very small (only 23AWG), we have to take into account a voltage drop. As a result, the farther away from the PoE switch, the less power is available at the point of load. PoE can only deliver 70W at the maximum range of 100 meters using Cat6 cable.

According to VoltServer, DE differs also from the Class 2 low-voltage power system, which provides 54V on 2A and goes over a 12/14/16 gauge cable. If we need to get power farther away from the power supply, we have to use thicker, less flexible, and more expensive cables. Class 2 can deliver only 80W at 300 meters using 14-AWG cable.

“Using the same wiring practices as low-voltage, we are able to deliver much higher power, and we can go much further than both PoE and Class 2: We can deliver up to 400W at 2 kilometers, 2,000W at 300 meters, and 2,400W at 100 meters,” said Getto.

Higher power is sent from the transmitter across the lightweight cabling to a receiver. There, using Vicor’s high-efficiency BCM6123 fixed-ratio converter, it can be converted down to loads. BCM6123 provides the power efficiency that allows the receivers to be placed in tight, enclosed spaces that are too small to permit the use of active cooling. This allows VoltServer’s platform to operate more efficiently with a much smaller receiver footprint.

In terms of applications, VoltServer Digital Electricity can be used for providing remote power to devices such as security cameras, access points or radios, IoT devices, and more. DE technology allows these devices to be placed nearly anywhere. The transmitter can be placed in a central location, together with a UPS, a battery system, or a generator that backs up all the power there.

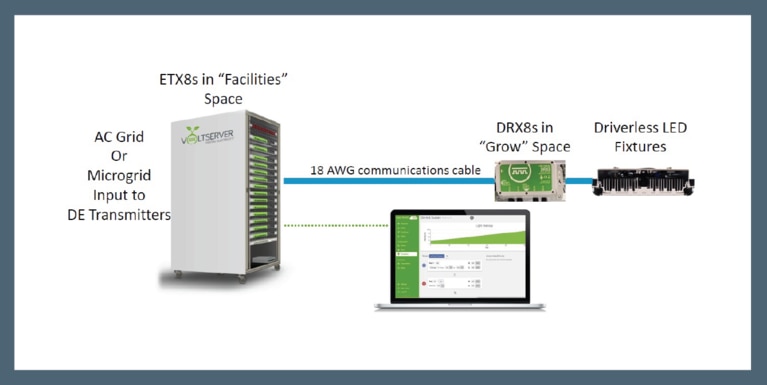

“One application in which we are doing a lot now is indoor farms,” said Getto. “In an indoor farm, you have to provide lights to the plants. You have to basically replicate the sun.”

What VoltServer offers here is more like an IT network, wherein DE can be plugged directly into the lights. This is an example of controlled environment agriculture, wherein LEDs can be controlled remotely through a dedicated software application, miming the sun’s behavior from sunrise to sunset. That allows each LED to be turned on or off, slowly ramping them up to full energy or ramping them down. The nice thing is that the cost of deploying those lights in an indoor agriculture facility is dropped by up to 20% to 30%, and the cost of running power to lights can be up to 50% of the capital to build an indoor farm.

Figure 3 shows an example of VoltServer’s Digital Electricity Agriculture Platform. The AC grid or microgrid input is connected to a set of ETX8 transmitters, capable of 3-kW output power on eight output channels. Each transmitter is connected to a DRX8 receiver through an 18-AWG communication cable. The receivers then drive the driverless LED fixtures, which provide the plants with the required light. A dedicated software application, running on a PC, controls the transmitter rack to implement custom lighting profiles.

Figure 3: VoltServer’s Digital Electricity agriculture platform.

Digital Electricity offers the benefits of low voltage with the power and distance capabilities of AC high voltage. It’s easier to install long runs using lightweight cabling, and it conforms to the NEC and CEC Code.

This article was originally published by Power Electronic News.

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity

Helping Hollywood fulfill its green ambitions

ReVolt is the cleaner, greener solution to the massive fossil fuel burning generators used on movie sets today. Learn how Vicor is helping ReVolt

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products