Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

Vicor power modules are the only solution capable of delivering the performance Microgate needed within such a compact footprint.

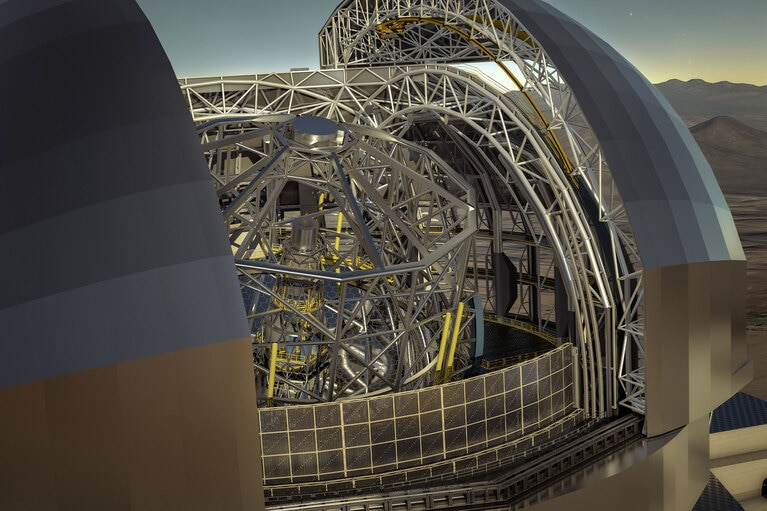

Uncovering the secrets of the Universe starts with a clear, detailed view. Unfortunately, this is a challenging task for Earth-based telescopes, because they need to overcome one major obstacle: the Earth’s atmosphere. That’s where Microgate’s adaptive optics, built for the European Southern Observatory’s (ESO) Extremely Large Telescope (ELT), come into play.

Figure 1: Microgate telescope.

Microgate, a company based in Bolzano, Italy, is a specialist in high-precision control systems. Currently, the company works on the adaptive mirror for the world’s largest optical telescope, powering its cutting-edge technology with Vicor high-density DC-DC converter modules.

Make no mistake, the ELT is quite an engineering achievement. With a primary mirror stretching an astonishing 39 meters in diameter, it should be able to capture the faintest traces of light from deep space. But light traveling from distant stars gets distorted as it passes through the atmosphere, degrading image quality. Adaptive optics are the solution — and they demand a power system that’s just as sophisticated as the technology they enable.

At the heart of the ELT’s adaptive optics system is a 2.4-meter secondary mirror, just 1.9 mm thick, fitted with over 5,300 voice coil motors. These motors deform the mirror in real-time to correct for atmospheric distortions; yup, they essentially delete the atmosphere from the picture. However, this process requires rapid, precise control and dense power distribution across a compact surface. Each motor operates in tandem with nanometer-accurate position sensors, continuously reshaping the mirror to restore a flat wave-front and produce sharp, high-resolution images.

Powering this entire process are the Vicor DCM3623 isolated DC-DC converter modules. Chosen for their compact size, thermal efficiency, and high power density, these modules allow Microgate to supply clean, reliable power to each motor channel while meeting the system’s tight spatial and thermal constraints. Mounted directly onto gas-cooled cold plates beneath the mirror, the DCM3623 modules eliminate complex wiring and support up to 36 motor channels each — a critical advantage in such a densely packed system.

According to Microgate hardware engineer Gerald Angerer, Vicor’s modules were the only solution capable of delivering the performance needed within such a compact footprint. “We’ve been using them (Vicor power modules) for over 10 years, and there is currently no comparable substitute,” said Angerer.

Thanks to Vicor power technology, Microgate’s adaptive optics system can reshape the mirror up to 1,000 times per second. Hence, they enable ground-based telescopes to rival space telescopes in clarity, while offering more flexibility and easier upgrades. In powering this optical precision, Vicor is helping astronomers and cosmologists push the boundaries of discovery, one photon at a time.

This article was originally published by Industry Tap.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

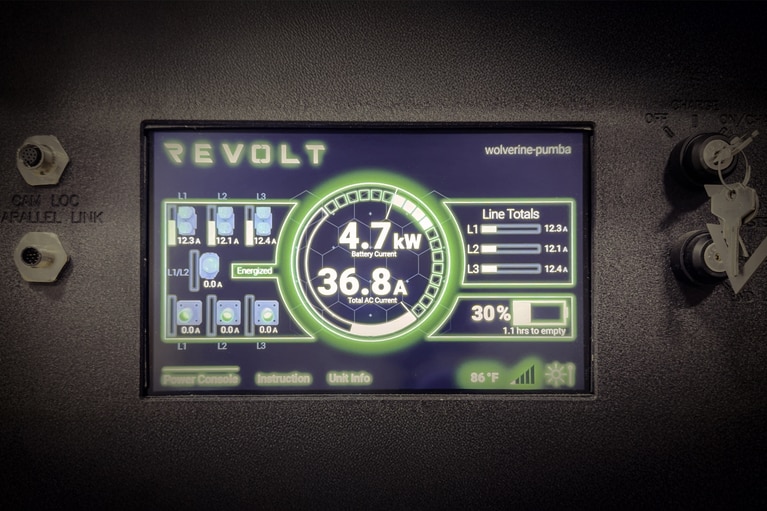

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity