設計 48V 供電網路時需考慮並攻克的 15 項技術挑戰

為幫助您全面備戰 48V 系統遷移,在開啟您的第一個 48V 設計時,請考慮以下 15 項技術挑戰

降壓調節是將 DC 電源的電能分配至負載點(PoL)的關鍵環節,傳統上通常採用脈寬調製(PWM)電路來實現,也就是通過改變 PWM 的占空比來滿足所需的降壓要求。

然而,有若干因素給穩壓器設計帶來了日益新增的壓力。 首先,隨著更强大的器件不斷被集成到電路板上,而電路板的尺寸卻並未相應新增,導致功率密度被迫提高。其次,為了降低配電損耗,DC 電源電壓趨於升高,而器件電壓則在降低以提高內部運行速度和效率。 這兩種趨勢疊加,共同新增了穩壓器兩端的壓降及相關的切換損耗。

例如,一個程序控制系統可能需要將電壓從 24V 調節至 3.3V——如此大的壓差通常需要兩級調節; 這會新增電路板空間和成本並帶來可靠性問題。 此外,穩壓器的切換頻率也受到限制,因為切換操作增多會帶來更多損耗。 這反過來又限制了使用更小的無源元件進行濾波,從而降低了整體解決方案的功率密度。

儘管高密度 PWM 穩壓器已隨著 IC 集成度、MOSFET 和封裝技術的優化而不斷發展,但其設計已不足以滿足所面臨的功率需求。 這主要是由於穩壓器 MOSFET 內的切換損耗。 要顯著提升穩壓器效能,必須克服或避免這些損耗。

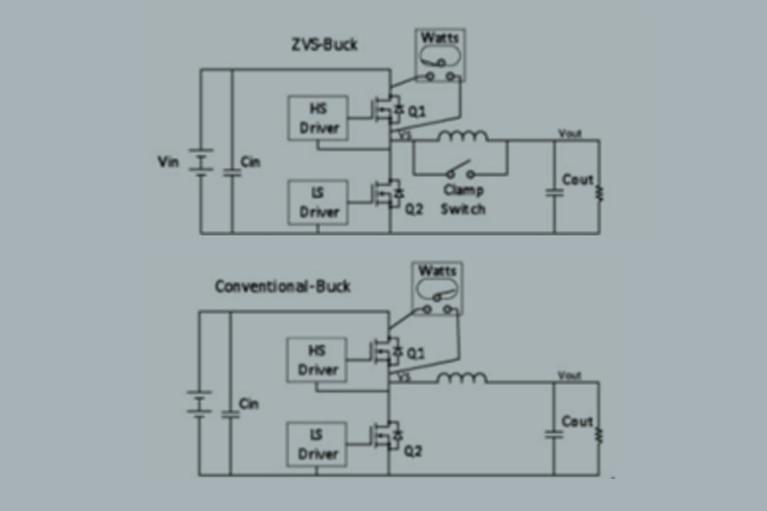

一種更好的解決方案是採用零電壓開關(ZVS)拓撲,它能支持以更高頻率和更高輸入電壓運行,而不會犧牲效率。 雖然仍基於 PWM,但在 PWM 時序中新增了一個獨立階段以實現 ZVS 操作。 圖1比較了傳統的降壓穩壓器和為 ZVS 操作而改進的版本。 利用新增的相位,ZVS 拓撲通過鉗比特開關和電路諧振,以軟切換方式高效地運行高壓側(Q1)和同步(Q2)MOSFET,從而避免其在傳統 PWM 操作和時序過程中產生的損耗。

例如,在傳統電路中,當 Q1 導通、Q2 關斷時,由於 Q2 的體二極體在其反向恢復時間內呈現短路狀態,會有非常大的尖峰電流流經這對 MOSFET。 其他損耗則源於 Q1 輸出電容的放電以及 Q2 的反向恢復。 這些損耗會隨著切換頻率或輸入電壓的新增而新增。

相比之下,ZVS 設計在高壓側 MOSFET 導通前,消除了由體二極體導通引發的大電流,解决了傳統穩壓器的高導通損耗問題,將高壓側 MOSFET 的D-S(漏-源)電壓降至零或接近零,從而不會產生大電流尖峰或有害的振鈴。 施加於 Q1 上的 ZVS 操作消除了其導通時的米勒效應,從而允許使用尺寸更小的驅動器和更低的柵極驅動電平。

Vicor 已在其降壓穩壓器產品中採用了 ZVS 拓撲。 相比傳統硬開關高密度穩壓器,這些產品能以高達 36VIN 的輸入電壓、更高的效率以及更小的外形尺寸提供穩壓調節。

圖 1:ZVS Buck

相關內容

產品概述:降壓穩壓器