15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

It’s not surprising that when you’re developing leading-edge power components you can’t just purchase all the test equipment you need off-the-shelf. Commercial systems can’t deliver all the comprehensive, accurate data required for documenting the actual performance of all parameters of device performance. So Vicor devotes a team of engineers – and a significant budget – to developing test equipment to help engineers and ensure outstanding quality of all the products leaving their production lines.

A core element of these tools is the design introduction verification analysis (DIVA) software, developed by Vicor to analyze and compare units and groups of units to generate specifications for the factory to ensure that at high volume production, units have acceptable CPKs (process capability index).

This specialized test equipment gathers sufficient data to establish that the product works to spec., design requirements are met, data sheets are accurate and that the company’s Whiteboard, which is a tool that simulates how Vicor products behave under all conditions, is loaded so that customers and FAEs get a clear and accurate view of the device performance.

The software and hardware used to examine every production part is almost an exact duplication of the design engineering ATE, so that production test routines are a subset of those used in engineering. This ensures that the performance of production parts doesn’t deviate from the data sheet specifications.

In manufacturing, all tests are made up of comprehensive functional measurements; the high density of these products means that there is just no space for conventional test points. This means that real-world testing of all parameters, at all loads, and at temperatures from as low as -55°C and high as 100°C is carried out on each device.

Vicor uses a universal software for test and analysis (USTA) tool which was designed and developed entirely in-house and allows engineers to simply fill in blanks on routines that have already been built; this is much faster than writing VB, Labview, etc. This also creates a consistency of testing from one product to another because the same USTA engine is used on disparate ATE hardware configurations, ensuring consistency throughout the whole test process.

The intensive focus on innovative test equipment allows for high yield and high mix production. Operators do not have to make the decisions on how to test; the company’s CIM system does all of this. Even the defined order of temperature testing (e.g. low, mid & high temp) is fixed; i.e. the operator cannot test high temperature first if the specification requires low-temperature testing to be carried out first.

Most high volume lines involve automatic handling. All devices have an assigned unique serial number so that Vicor – and importantly, customers – can access actual test data for individual units; a valuable facility that has been available for customers for many years, especially impressive when the company currently tests over 20,000 devices per day.

It’s not common practice for a power supply company to invest in this high level of testing; with Vicor it is more like a semiconductor manufacturer’s process giving full traceability for individual devices and is a huge confidence-building factor for the customer as well as an important differentiator for Vicor.

In addition, the large test engineering department with several test engineers in the design engineering department and a skilled IT team to support the processes speed up the verification of manufactured units. The company’s PCB layout, mechanical design and robot handlers for products represent a significant investment. Customers value and benefit from this intensive testing.

Data Acquisition Test Setup

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

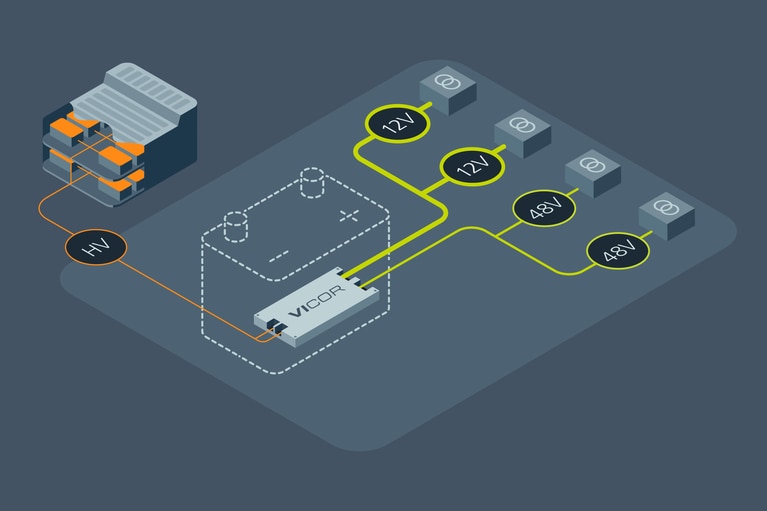

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

電源模組助力簡化電動汽車的爬電距離與電氣間隙設計

包覆成型(Overmolding)是解决48V汽車電源系統中電弧問題的關鍵

壓力下的動力:滿足軍事領域激增的電力需求

軍事電源系統設計者需要更多的效能(功率)和兼容性。 瞭解 Vicor SOSA 電源如何解决難題