ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

Vicor's Factorized Power Architecture utilizes a PRM™ buck-boost voltage regulator and a VTM™ to support electrolysis.

Off the coast of the Yucatán Peninsula lies the Mesoamerican Reef, which, like all coral reefs, is one of the most biologically diverse ecosystems on the planet. However, rising temperatures across the globe are affecting marine life just as much as terrestrial life. As seas get warmer, ocean acidification increases, and oxygen levels in the water drop, coral reefs like the Mesoamerican Reef are experiencing a fatal health crisis known as “white syndrome,” a disease that can kill corals in under 40 days.

But the effects of this disease aren’t limited to the corals themselves, or the marine life that relies on the reefs. Or even the ocean.

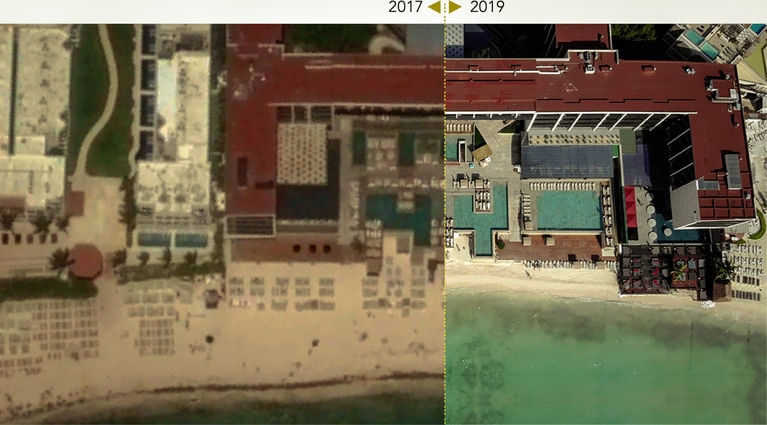

Reefs serve as a barrier between powerful ocean waves and the beaches of coastal cities and structures. Without the reefs to impede the perpetual energy of the tides, waves are crashing onto shore at full force and rapidly eroding the coastlines of popular beaches (Figure 1).

Figure 1: In some areas, beaches are shrinking by as much as one meter every six months.

But humans have discovered a way to help rebuild those dying coral reefs in an effort to preserve what remains of those beaches. CCell Renewables, a U.K.-based company working around the globe to prevent – and even reverse – coastal erosion, developed a strategy to accelerate coral growth on submerged steel structures using a process called electrolysis.

CCell has spent many months working on pilot projects in Cancún and Telchac, which lies on the northern coast of the Yucatán. The reef project is designed to mimic the natural growth conditions of coral reefs, which, on their own can take hundreds of years to reach maturity.

With CCell’s artificial reef structures, this process can occur in as little as 36 months.

“What's crucial here is that you can't just put those corals on plain sand, they'll just sink into the sand and disappear,” says Dr. Will Bateman, CEO of CCell. “What we're doing is providing almost like a backbone on which they can be placed.”

The foundation of the artificial reef is a series of 2.2-meter steel, half-tunnel cage-like structures (Figure 2). These structures are electrified by precisely-controlled 1.2 to 6V electrical currents that run through a small metal anode. The cathode, which, in this system, is the reef structure itself, increase the pH levels of surrounding water, which causes salts to dissolve against the steel surface of the cage.

Figure 2: Artificial reef structures are submerged along the Telchac coastline to impede wave energy and preserve beaches.

Oxygen produced by the anode’s low-level voltages combine with the soluble effects of the cathode to enable the formation of aragonite (calcium carbonate) and brucite (magnesium hydroxide) rocks that attach to and seal the cages, protecting them from corrosion (Figure 3).

This entire process is dependent on precision voltage control between the remotely managed anodes and cathodes. In a single month, a 3-5mm layer of rock can form over the structure.

If insufficient voltage is applied, the rock formations can become spongy and unsuitable for the hatchery-grown corals. You can imagine what too much electricity would do in this environment.

But even if rock successfully bonds to the steel cage so that divers can place local coral polyps by hand, the work isn’t done. CCell’s electrolysis process must continue for the attached corals to grow at the 3-5x accelerated rate needed to form mature reefs in three years.

Figure 3: The current supplied to the artificial reef structures enables the formation of rock to protect the steel from corrosion and provide secure attachment for coral polyps.

“The last thing we want to be doing is continuing to grow rock when that process is happening, because we end up entombing the poor little coral polyps,” Bateman said.

CCell’s team has had to learn to interpret environmental conditions in the water to determine when a reduction – or even complete cease – of power input is warranted to slow the expansion of rock and maximize coral growth.

Power for the CCell electrolysis process is generated by multiple sources. Some of it is drawn from conveniently-renewable resources courtesy CCell’s own wave-energy converter, which powers an electricity-producing hydraulic system with a paddle. Depending on wave conditions, this system can produce a range of voltage levels between 35V and 70V, which is then converted, controlled, and monitored by the electrolysis system itself.

Bigger pilots, like the one in Telchac, garner supplemental power from solar energy. With only a couple hundred watts available, smaller pilots, like those in Cancún, can’t harvest enough renewable energy and source their power from other means.

Sources aside, the power gathered must be transmitted to electrolysis systems at the pilot reef sites. This is achieved through a power delivery network (PDN) consisting of a front-end conversion regulation stage and a downstream point-of-load (PoL) regulation stage that delivers power to the electrolysis system over a cable.

But, as stated, the amount of power delivered to the system must be finely controlled. To maintain the peak current of 10A and 50W of power required for each length of reef, CCell leveraged Vicor’s Factorized Power Architecture that integrates a pre-regulation module (PRM) buck-boost voltage regulator and voltage transformation module (VTM) current multiplier with fast transient response (Figure 4). The PRM inputs unregulated voltage and outputs regulated voltage, which is used to drive the VTM.

Figure 4: Vicor's Factorized Power Architecture (FPA) utilizes a PRM buck-boost voltage regulator and a VTM to send power to CCell's electrolysis system.

“The VTM is, alternatively, a current multiplier,” says Philip Simpson, a field application engineer at Vicor. “A VTM acts as though it’s effectively a DC/DC converter.

“They're a DC-to-DC transformer, conceptually, with what we call a K factor, which is equivalent to a turns ratio in a transformer-type application,” he continues. “The combination of the PRM and VTM gives you the ability to take reasonably high-voltage DC and convert it to quite low-voltage DC at relatively high current, but in a very efficient way.”

“The combination of PRM and VTM that CCell are using gives efficiencies well over 90 percent,” Simpson explains. “It acts as an ideal transformer.”

In Cancún, 50 such control units are currently deployed along 120 meters of reef.

So far, the results are encouraging, with wave attenuation at the test sites projected to improve to 30 percent in the next year. For context, while global wave energy has increased by 0.41 percent annually as a result of global warming, just a five to eight percent reduction in wave energy would restore the near-shore wave climate to levels from almost two decades ago.

The shape and porous structure of CCell’s artificial coral reefs work to stop larger waves from crashing onto the shore but allow smaller waves that deposit sand on beaches to pass through and rebuild what’s been lost.

There are currently plans to extend the artificial reefs by another 1 km along the Yucatán coast.

However, just as coastal erosion is not a phenomenon unique to one geographical area, CCell’s goals are not confined just to Mexican coasts. The company has been working on artificial reef structures in Israel, the Maldives, and elsewhere, all to stop – and hopefully reverse – erosion taking place across more than half the Earth’s coastlines.

Future goals for CCell include a potential partnership with Cornell University to implement acoustics on the reef structures that would mimic the sounds of living, thriving reefs to help attract marine life to the project sites.

This article was originally published by Embedded Computing Design.

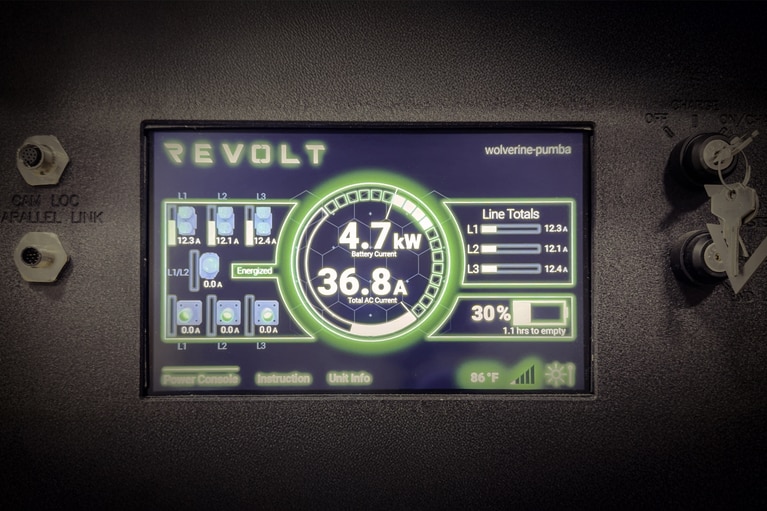

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity

Helping Hollywood fulfill its green ambitions

ReVolt is the cleaner, greener solution to the massive fossil fuel burning generators used on movie sets today. Learn how Vicor is helping ReVolt

16th Asia Power Technology Development Forum 2025

Vicor presented high-density DC–DC power modules maximize ATE throughput