SeaRAY leverages Vicor tech to convert wave energy

C-Power provides reliable, cost-effective ocean wave energy generation and storage. Vicor power modules support efficient kinetic energy conversion

Efficiently turning ocean wave into power is very challenging given the wide input range (the varying size of ocean waves). C-Power and Vicor have partnered to create an efficient power delivery network to harness waves and store power.

By Stephen Germino, Media Relations & PR, Director

C-Power autonomous offshore power systems promise to unlock new marine applications through efficient energy delivery and remote, high-bandwidth communications.

The ability to harness ocean wave energy is a rapidly evolving field that marine engineers are refining to provide reliable, cost-effective maritime energy generation and storage while enabling new forms of offshore data and communication services.

Columbia Power Technologies, Inc. (C-Power), a global leader in wave energy systems based in Corvallis, Oregon, is helping to expand the marine economy by providing reliable, cost-effective energy generation and storage, data, and communication services for offshore assets. C-Power autonomous offshore power systems (AOPS) capture mechanical wave energy and convert it into usable power for a wide range of oceanic applications such as offshore oil and gas exploration and production, offshore carbon sequestration, oceanographic research, aquaculture, and homeland defense.

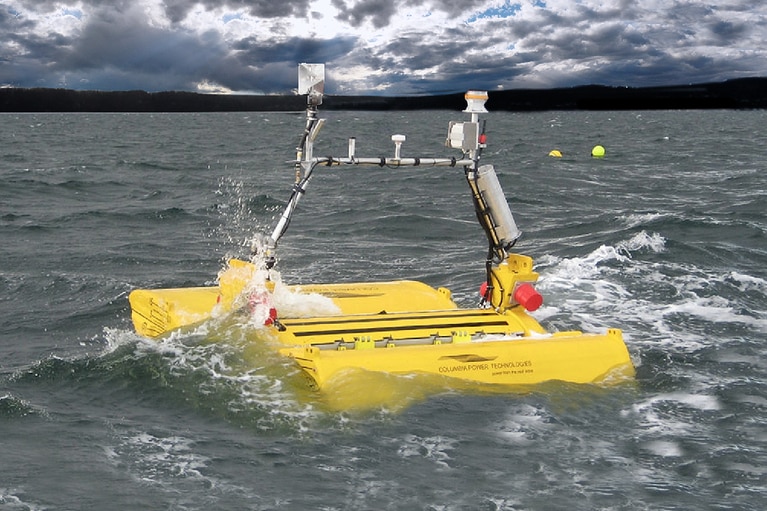

Founded in 2005, C-Power has evolved its focus as its expertise in the burgeoning field of oceanic energy harvesting has grown (Figure 1). While other companies pursue large, megawatt systems, C-Power focuses on remote, kilowatt-scale power for offshore data communications networks, initially through a DARPA project called Wave Energy Buoy Systems (WEBS).

Through the WEBS project, C-Power discovered a nascent opportunity in the form of localized power generation for underwater vehicles, subsea operating equipment, and open-ocean sensors used to collect environmental data. Previously, power for these applications was generated using expensive, cumbersome, non-rechargeable onboard batteries or subsea electric tethers fed from a ship or diesel generator. With the development of AOPS, C-Power opened the door to unimagined new applications by supplying an autonomous, environmentally friendly, ocean-borne power source capable of doubling as a communications conduit.

Figure 1

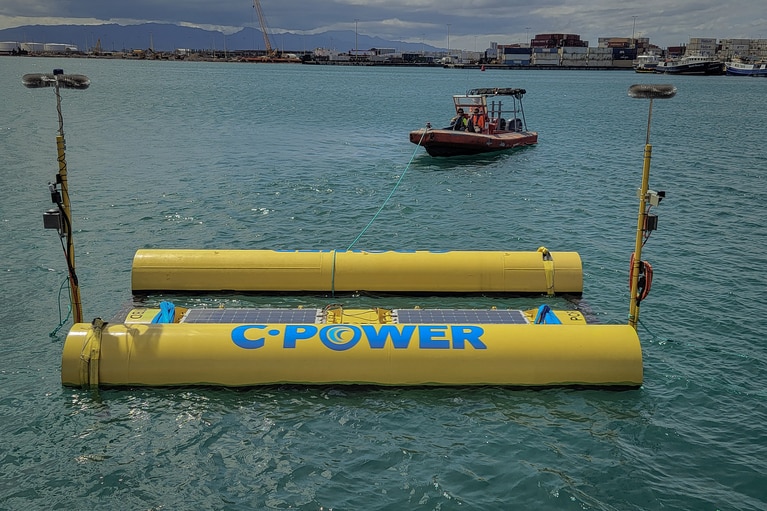

The latest AOPS platform, known as the SeaRAY, is key to the near-term focus of C-Power to produce power systems that generate 10W to 1MW from ocean waves. To achieve its goals at the lower end of the power spectrum, C-Power created a SeaRAY AOPS design with a high power-to-weight ratio using power conversion technology from Vicor Corporation. The small design footprint enhances mobility and commercial viability, making SeaRAY easier to deliver and set up, saving tens of thousands of dollars in daily operating costs.

“We really needed wide-range DC-DC, something that we could control and regulate as we’re converting pulsed ocean wave power into a semi-stable DC bus,” said Joe Prudell, a C-Power senior R&D electrical engineer. “This is extremely challenging. Being able to do that at various power levels using Vicor’s power modules really is an advantage.”

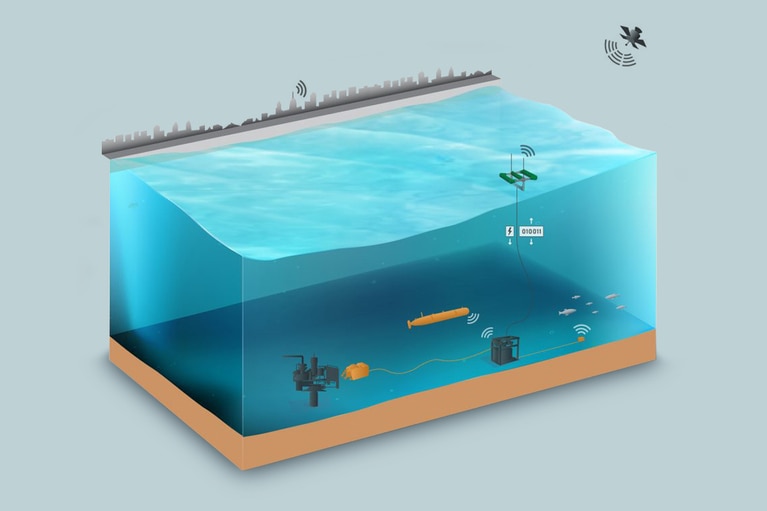

Figure 2: The SeaRAY design makes remote, autonomous data communications possible by sending information from the ocean to the cloud. Using cellular networks and satellite communications to pass data in real-time between the cloud and the SeaRAY AOPS allows more and richer data to be collected and delivered more often.

The SeaRAY design also makes autonomous, remote data communications possible by transmitting what happens in the ocean to the cloud in real-time. Previously, marine data-gathering systems have been limited in the breadth and frequency of data collection. Using cellular networks and satellite communications to pass data in real-time between the cloud and the SeaRAY allows more and richer data to be collected and delivered more often (Figure 2).

The key power design challenge for C-Power was to reconcile complex ocean wave energy properties with the demanding power conversion requirements of the SeaRAY. This included an ultra-wide 30:1 input range, which reflects the unpredictable nature of ocean waves. The Vicor Power Systems design team delivered a system capable of converting power with high efficiency and charging energy storage devices. The unit is also capable of accepting external control signals from the C-Power system to match precise power conversion needs in real-time.

“The ability to convert a very nasty power profile into a cost-effective, practical solution, and then condition that power and turn it into usable energy for a wide range of mobile and static payloads, is really on the leading edge,” said C-Power CEO Reenst Lesemann. “There’s nobody else that’s been able to do that yet.”

The scalable power design of the SeaRAY uses Vicor BCM® fixed-ratio bus converters and PRM™ regulator modules with complex multistage discrete converters to efficiently convert turbulent, unpredictable wave energy and provide controlled power. This enabled C-Power to increase the SeaRAY design’s conversion efficiency from about 50 percent to a range of 85 to 94 percent.

In Figure 3 SeaRAY uses the Vicor BCM® fixed-ratio bus converter and PRM™ regulator modules with complex multistage discrete converters to efficiently convert wave energy and provide controlled power. Using power modules Vicor developed a power delivery network that improved the SeaRAY conversion efficiency from 50% to over 90%.

The use of stable, wide-input Vicor DC-DC converters provided C-Power much-needed control as the SeaRAY converts pulsed ocean wave power into a varying DC bus while still producing a constant current at various power levels. In addition, the power conversion topologies used in Vicor modules help to minimize electromagnetic interference and noise onboard the SeaRAY that could otherwise compromise sensor measurement accuracy.

There are plenty of companies trying to capture and convert wave energy, but it’s another thing to do something in a small, compact form factor and still satisfy what customers need from an operational and logistics perspective,” Lesemann said. “That’s where we, with Vicor’s assistance, have been able to stick our chins out so much further than everyone else.”

Figure 3: SeaRAY uses the Vicor BCM® fixed-ratio bus converter and PRM™ regulator modules with complex multistage discrete converters to efficiently convert wave energy and provide controlled power. Using power modules Vicor developed a power delivery network that improved the SeaRAY conversion efficiency from 50% to over 90%.

This article was originally published by COTS Journal.

Steve Germino is currently the Director of Media Relations and PR for Vicor. He has served in marketing and public relations over the past 6 years, elevating the brand and helping to penetrate new growth markets. He has over 30 years of sales and marketing experience in technology, semi-conductors and the electronics industries.

Stephen Germino, Media Relations & PR, Director

SeaRAY leverages Vicor tech to convert wave energy

C-Power provides reliable, cost-effective ocean wave energy generation and storage. Vicor power modules support efficient kinetic energy conversion

Powering Innovation eBook: Volume 1 – Saving the environment

Technological breakthroughs to protect and preserve the environment

VideoRay drives safe, effective underwater exploration leveraging AI and today’s newest technologies

Vicor Powering Innovation podcast discusses the proliferation of ROV applications and how VideoRay is responding to new underwater missions

The best battery on Earth is free and it is powering the new Blue Economy

C-Power autonomous offshore power systems (AOPS) float in the ocean, capturing mechanical wave energy and converting it into usable power