Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

We will be conducting maintenance on the website Feb.13th between 11:30am and 1:00pm EST. Some parts of the site maybe offline during this time. We apologize for any inconvenience and thank you for your patience.

In cities you’ll often see large full-color LED video displays used for advertising that cover the sides of buildings. With each pixel of the display driven separately, there are challenging demands on the power systems used to convert AC power into the constant current needed to drive the LEDs.

These systems have demanding requirements for the power components they use. Power system cost is an obvious issue, with a large number of power components required to create one of these displays. It’s not surprising that efficiency is also a concern, as the electricity consumed is a key element of running costs and advertisers do not want to be portrayed as wasting money.

The reliability of LEDs decreases with temperature, meaning that if the heat dissipated by the power systems can be reduced, then the lifetime of the LEDs can be extended. It is also often possible to run the LEDs at higher intensity, increasing the brightness of the display. Heat can also change the intensity and the wavelength of the LEDs’ output, resulting in inconsistent illumination across the display.

Power components used in these systems must also operate reliably, whether in direct summer sunlight or in the middle of a winter snowstorm. Failures are particularly expensive due to the cost of repairing or replacing modules that are attached high on a building. As with architectural lighting applications, the costs and dangers of having someone replace parts at height far outweighs the cost of the replacement module.

Perhaps surprisingly, size is also an important criteria. These displays have to be thin to ensure they are mounted as close to the building as possible, and unnecessary weight can also add to the cost of deploying these displays.

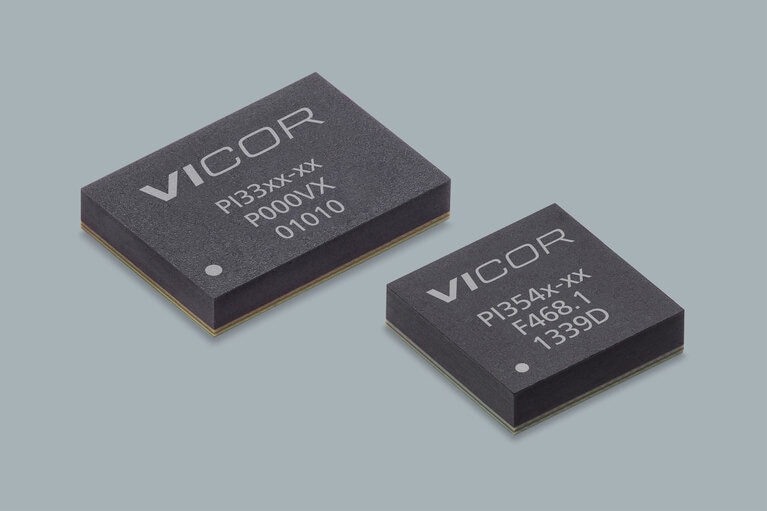

Vicor power components are ideally suited to these applications, due to their power density, efficiency and reliability. Recently, we’ve seen customers choosing our 48V Buck Converters, which were recently named one of EDN’s Hot 100 Power Components, to help them achieve their design goals. By offering a compact and efficient 48V direct to point-of-load conversion solution, they allow manufacturers to distribute power in these systems using a SELV 48V bus.

Today most displays distribute power using AC mains to each panel. This approach offers several downsides compared with the use of 48V: there are significant safety considerations associated with the use of mains voltages, and the losses in the AC-DC conversion generate heat that will affect the lifetime, brightness and color produced by the LEDs.

By converting directly from 48V, designers of large displays are able to simplify their power chains, reducing the number of stages, components required and cost of the system, while increasing the efficiency. Vicor Buck Converters make the displays reliable and easier to install, cutting the cost of installation and maintenance.

Related content

Product overview: 48V Buck Converter

Industries and innovations: LED lighting

Vicor power components, ZVS Buck family

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

Power under pressure: Meeting the military’s surging energy demands

More capability (power) and compatibility are in demand for military power system designers. Learn how the Vicor SOSA Power Supply solves this problem

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power