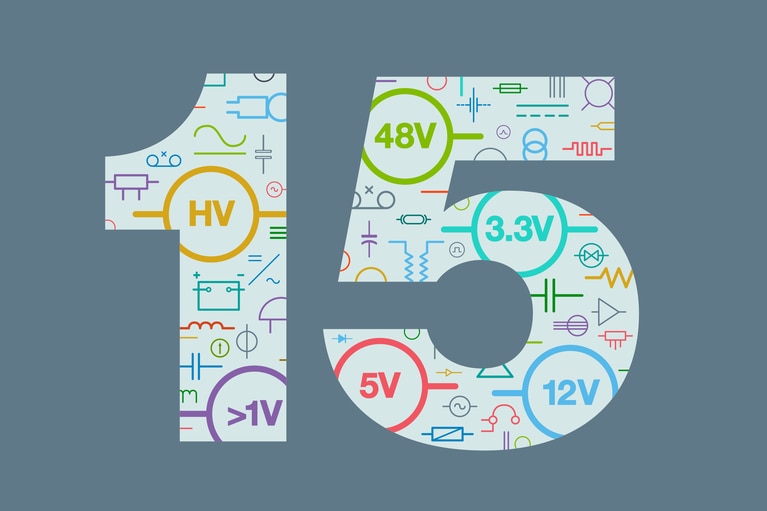

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

要直觀地說明電源時序的重要性,可以設想在一個大型工業系統中,如果其電機和執行器先於控制電子設備通電會發生什麼情况。 顯然,必須通過精心設計的電源啟動順序來徹底消除此類不可預測且危險的隱患。 同樣,關機順序也至關重要。

錯誤的電源時序不僅會在半導體器件層面,還會在系統層面引發問題。 例如,這些問題可能導致 CMOS 器件出現意外的反向偏置,從而損壞或摧毀該器件,或將其鎖定在只能通過重啓電源才能解除的導通狀態。 儘管阻塞二極體可以防止閂鎖效應,但會限制可用類比輸入電壓的範圍,因此採用電源電壓啟動時序是首選解決方案。 此外, DSP、 微處理器等多電壓器件通常要求先提供 I/O 電壓再施加內核電壓。 英特爾處理器晶片檔案中通常會明確說明必須遵循的啟動與關斷順序。 同樣,CPU 晶片必須在系統圖形 IC 之前上電,以防止向圖形顯示器輸出失控訊號。

典型的電源時序方法有兩種:一種基於電源,另一種基於邏輯。

“電源”解決方案利用某一電源軌的電壓上升訊號,向 N 溝道 MOSFET 發送一個適當延遲的觸發訊號,從而控制第二個電源軌的供電。 “邏輯”解決方案則基於電源模組器件(power train device)的使能(Enable)引脚或其他邏輯引脚進行控制,而非直接控制其供電電源。 利用電源組件內部集成的邏輯可實現成本更低、結構更緊湊且更簡潔的解決方案,但在要求更高的應用中,MOSFET 能提供更精確的導通時間控制。

下圖 1 展示了一個採用 N 溝道 MOSFET 和比較器的基礎 MOSFET 時序電路。 VREF 用於設定 VCC2 的切換閾值,VCC2 將在 VCC1 啟動後經過 RC 網路設定的延遲時間才啟動。 MOSFET 驅動器內寘一個電荷泵,確保 VGS 比 VCC2 高出數伏,從而完全增强 MOSFET 切換。 該電路也確保 VCC2 會隨 VCC1 關閉而關斷,但由於 RC 網路的存在,VCC2 的關斷會滯後於 VCC1。 此外,如果 VCC1 無法用作參攷電壓,可能會出現其他問題。

圖 1:採用 RC 網路、比較器和 MOSFET 驅動器的電源時序

目前已有集成度更高、更簡便的解決方案,如圖 2 所示的示例。

圖 2:採用 MAX6819 的電源時序

該時序器確保 MOSFET 始終獲得所需的最小 VGS 增强電壓,從而最大限度地减少 MOSFET 的損耗,並確保較低的漏源阻抗(RDS(ON))。 MAX6819 預設了 200ms 的出廠固定延遲時間,該延遲發生在主電壓超過設定閾值之後、啟用電荷泵驅動外部 MOSFET 切換之前。

Vicor 穩壓器、VI Chip 及磚型產品可通過上述 MOSFET 電路實現時序控制,也可如前所述通過其控制引脚和內部邏輯進行管理。 一種簡單的配寘方式是,將某器件的“軟啟動”輸出連接到另一器件的邏輯使能/禁用引脚,從而有效控制其電源時序。 此外,許多 Vicor 器件都配備電壓控制引脚或觸發引脚。 如果向該引脚施加斜坡電壓,器件的輸出將隨電壓控制輸入呈斜坡變化,但會存在固定的時間延遲。

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

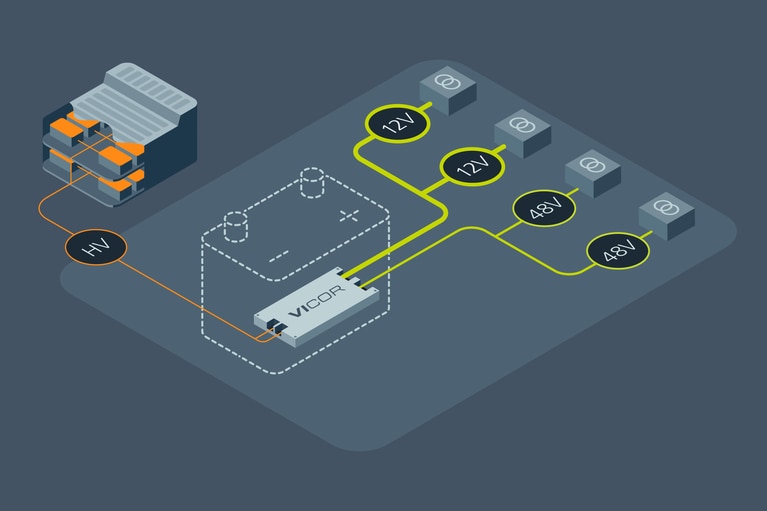

面向未來的汽車高壓轉 SELV 方案

傳統的 12V 架構已無法承受車載電子負載的不斷增加。 瞭解電源模組如何加速向 48V 的轉型

電源模組助力簡化電動汽車的爬電距離與電氣間隙設計

包覆成型是解决 48V 汽車電源系統中電弧問題的關鍵

壓力下的動力:滿足軍事領域激增的電力需求

軍事電源系統設計者需要更多的效能(功率)和兼容性。 瞭解 Vicor SOSA 電源如何解决難題