Hongfa compact active suspension power design will transform driving.

Hongfaのアクティブサスペンション用コンパクト電源、Vicorの小型電源アーキテクチャを採用

高電力密度の電源モジュールと48V電力供給ネットワークにより、車の走行性能が飛躍的に進化。中価格帯の車にも高級車並みの機能を搭載可能に。

※ 本リリースは、2025年5月21日(米国東部時間)に発表されました。

Vicor Corporation(本社:米国マサチューセッツ州、CEO: Patrizio Vinciarelli、NASDAQ上場:VICR、以下Vicor)は、Xiamen Hongfa Electroacoustic Co., Ltd.(本社:中国、以下、Hongfa)が、同社のアクティブサスペンションに、Vicorの電源モジュールを採用したと発表しました。

Hongfaは、長年にわたり高級車向けだった機能を中価格帯の車両に導入することを目標に、業界で最も高性能かつ最小サイズのアクティブサスペンション用電源システムを設計しました。自動車の大手メーカが何十年もの間挑んできた、アクティブサスペンションシステムに求められる「小型軽量化・過渡応答性能」と「高効率化・EMIの改善・対称的な電力回生機能」の両立を、 Hongfaは見事に実現しました。

Hongfaは自動車向けの電力管理と配電が専門で、リレーの技術により新しい48Vゾーンアーキテクチャを支えます。そうした中、HongfaはVicorと提携し、電圧変換比固定の800V-48V DC-DCコンバータ電源モジュールを導入しました。このモジュールは、センサー群 や電気機械式アクチュエータ、高度なソフトウェアで構成されるネットワークと並んで設置され、サスペンションをリアルタイムで調整することを可能にしています。このコラボレーションにより、競合製品のおよそ半分のサイズの業界最小のアクティブサスペンションシステムが実現しました。電力変換の過渡応答も業界最速です。

高電圧バッテリーと48V電力供給ネットワークが、アクティブサスペンションシステムの本格的な進化を後押し

古い幹線道路や田舎の砂利道、郊外のデコボコ道であっても、アクティブサスペンションを使えば操縦性や乗り心地、安全性を高めることができ、走行音も低減できます。1970年代初頭の業界の初期の取り組みでは、12Vバッテリーの電源システムに過大な負担がかかる複雑な電磁式ソリューションが使われ、200ポンド(約90kg)のモーターを4基も搭載する必要がありました。

従来、12VDCはアクティブサスペンション用のモーターを駆動するには電力が不十分であり、サイズや重量、コストの増大は避けられませんでした。また、一部の従来型DC-DCコンバータは中間バッテリーを介さずに電力を供給できますが、大型であり、再生エネルギーを回収・蓄電するために必要な高速の過渡応答ができないという課題がありました。

これまでアクティブサスペンションシステムは多くの電力を消費する負荷でしたが、近年のメインバッテリーの高電圧化(400Vまたは800V)と、自動車業界で採用が進む48V電力供給ネットワーク(PDN)の組み合わせの恩恵を受けます。この組み合わせはすでにプラグインハイブリッド車(PHEV)やバッテリー式電気自動車(BEV)の電源として活用されています。

Vicorの電圧変換比固定800V-48V DC-DC バスコンバータBCM®は本質的に双方向変換ができるコンバータであり、DC-DCコンバータトポロジの中で最も高速の過渡応答(毎秒800万アンペア)を実現しています。またBCMは、昇圧・降圧のどちらの向きも同じ電力レベルで動作でき、対称的な双方向変換性能を備えています。先進の平面パッケージなので放熱設計が簡素でき、システム全体の設置面積と重量をはるかに低減することができます。

双方向変換に対応したコンバータを通して、アクティブサスペンションをメインバッテリーに直接接続することで、最適なエネルギー回収が実現します。バネがエネルギーを吸収して放出するように、アクティブサスペンションは回生式のショックアブソーバで運動エネルギーを回収し、バッテリーに戻します。

図1: Hongfaのアクティブサスペンションシステム (電源システム仕様: HF3661 800V-48V DC-DCシステム) は液冷式で、重量2.6kg、サイズ197 x 201 x 71mmと、市場で最も小型な製品です。

電源モジュールと48Vで実現したHongfaの小型アクティブサスペンションシステム

Hongfaのソリューションは、Vicorの高電力密度電源モジュールを使い、各アクチュエータ用にコンパクト(197 x 201 x 71mm)な5kW電源を構築しています。このシステムは、瞬時に6kWまでのピーク電力を扱うことができ、双方向の変換動作が可能です。VicorのBCM6135モジュールを2つ並列接続して使うことで、コンバータの設計を大幅に簡素化することができ、何百ものディスクリート部品は必要なくなります。

このコンバータは800Vバッテリーシステム用として最適に作られており、動作する電圧範囲は420V〜920Vです。液冷式で、最大100アンペアの電流を97.3%の効率で供給できます。システムの筐体容積は1.8リットル未満、重量は2.6kgと、他のシステムに比べて大幅な小型・軽量化を実現しています。

Hongfaの研究開発ディレクターであるPeter Li氏は、次のように述べています。「アクティブサスペンションにおいては、応答時間がミリ秒単位のDC-DCコンバータが求められます。応答が遅いと、バッテリーを追加しなくてはなりません。Vicorの電源モジュールBCM6135を導入したことで、求める性能が実現しただけでなく、開発期間が大幅に短縮され、システム設計がとても簡単になりました。」

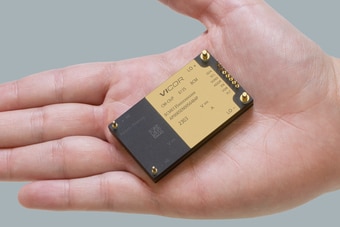

図2: 双方向変換が可能なBCM6135 は、電流の応答速度が毎秒800万アンペアと極めて高速なので、アクティブサスペンションやエネルギー回生の電力プロファイルの対応に理想的なモジュールです。BCM6135は、95%の効率で3.5kWのピーク電力に対応する800V-48Vバスコンバータで、対称的な電力スイッチング性能を備えています。

48Vアーキテクチャと高電力密度電源モジュールを組み合わせることにより、スペースと重量を減らしながら優れた性能を実現し、自動車の電動化に画期的な技術革新を起こすことができます。HongfaとVicorは、それぞれの自動車分野における専門知識を活かして先進技術の開発に取り組み、高性能電気自動車の発展を支えています。

ケーススタディ「アクティブサスペンションの長年の電力課題を解決する48Vと高電力密度のモジュール」をあわせて読む

Vicor について

Vicorは高性能電源モジュールのリーディングカンパニーです。電力源から負荷点まで高い電力密度と高効率を実現する電力供給ネットワークを、モジュールで構成する電源システムソリューションによって実現し、お客様の技術革新に貢献しています。配電アーキテクチャ、電力変換技術、パッケージ技術を、長年にわたり進化させることで、Vicorの電源モジュールは、電力密度、効率、電力容量の向上を続けてきました。Vicor は、ハイパフォーマンスコンピューティング、産業機器、自動車、航空宇宙・防衛などのお客様に製品を供給しており、要件の厳しい産業分野で、電源モジュールの設計、開発、製造を40 年以上続けています。

詳しくは、Vicorウェブサイト: www.vicorpower.com/ja-jpをご参照ください。

Vicor、BCM® は、Vicor Corporationの商標です。

Xiamen Hongfa Electroacoustic Co., Ltd (Hongfa) について

Hongfa は、世界最大のリレー・メーカーであり、パワーリレー、車載リレー、 HVDCリレー、ラッチ型リレー、信号リレーにおいてトップシェアを誇ります。Hongfaのリレー製品には、パワーリレー(一般リレー)、車載リレー、高電圧DCリレー(DCコンタクタ)、ラッチ型リレー、信号リレー、産業用リレーなどがあります。全体で160以上のシリーズがあり、40,000以上の標準仕様に対応し、年間生産量は30億個を超えます。製品はUL(C-UL)、VDE、TÜV、CQCなどの安全規格の認証を受けています。