Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

With each passing year, electric vehicles (EVs) on the market are becoming increasingly reliant on electrically actuated systems, such as steer-by-wire, brake-by-wire and active suspension. In fact, over 40% of new vehicles in the first half of 2024 were fitted with brake‑by‑wire systems, which was a 20-percentage‑point increase over the previous year. [1]

By Roberto Cappelloni, Global Account Manager

Common to each of these increasingly ubiquitous subsystems is their inherently inductive nature, which requires fast, high-current driving pulses to operate effectively. As a result, power delivery net-works (PDNs) in modern EVs must simultaneously support steady-state loads as well as high-slew-rate current demands and brief, high-magnitude peaks.

Ultimately, meeting these requirements is only possible through power converters that can respond on the microsecond timescale while handling power levels that momentarily exceed their continuous ratings. In practice, this means a high rate of current change (di/dt) capability and peak power handling that does not come at the expense of size, cost or thermal overhead.

Yet, traditional DC-DC architectures struggle in this domain. Their control-loop bandwidth, reliance on output filtering, and thermal limitations make them ill-suited for rapidly changing load conditions. To support the next generation of EV features, the industry needs to reimagine the underlying power architecture.

Beyond component-level performance, modular converters offer substantial architectural advantages that ripple through the entire vehicle platform. By integrating magnetics, control and thermal interfaces into a compact package, Sine Amplitude Converter (SAC™) modules drastically reduce the thermal footprint of the power stage. Efficient conduction paths and minimized parasitics trans-late to lower junction temperatures and let designers simplify or downsize heat sinks without compromising reliability.

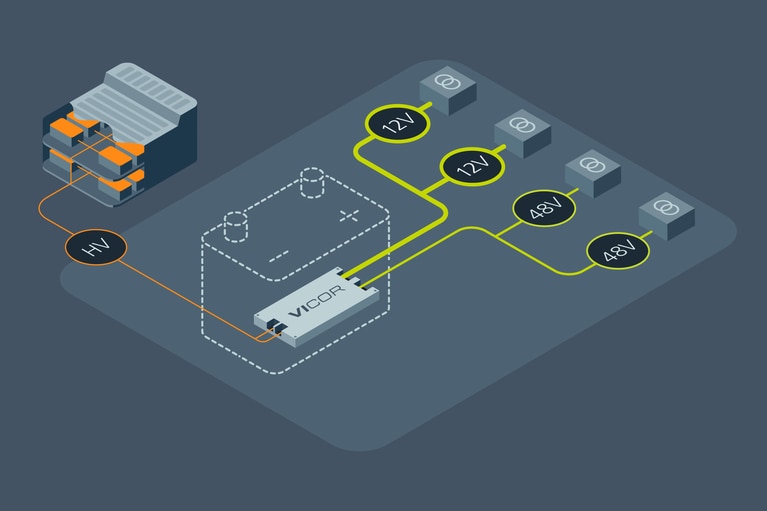

The high-power density achievable with modern modular designs (often exceeding 3kW/L) reduces the need for multi-stage conversion. Instead of distributing power through a cascade of regulators, designers can deliver the required voltage and current directly at the point-of-load with shorter wiring runs and smaller overall enclosure size. Such an architectural simplification also supports the broader industry push toward zonal power distribution, where subsystems receive local, regulated power via short, efficient links rather than drawing from centralized 12V or 48V buses.

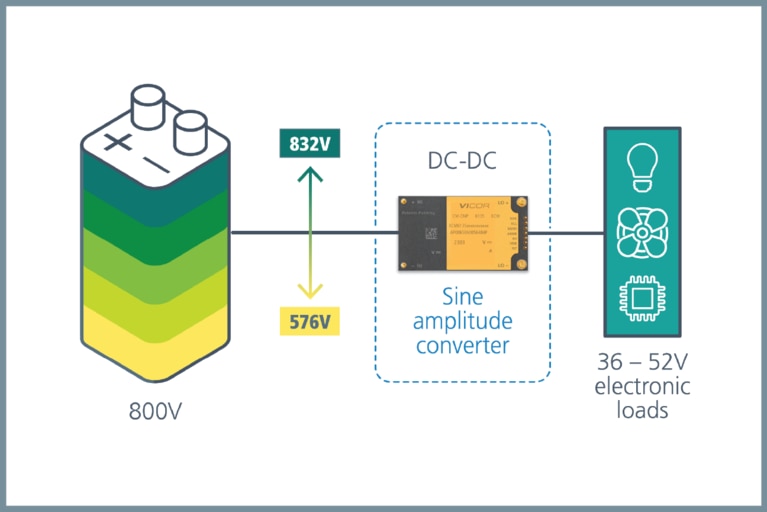

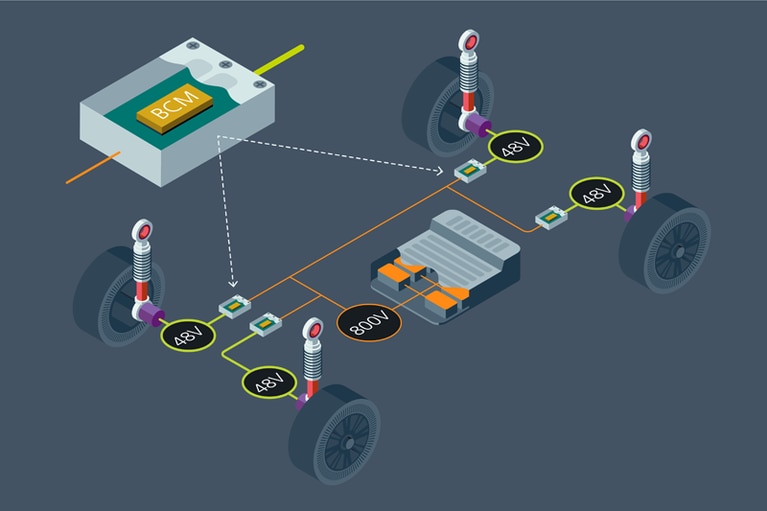

In many cases, the fast transient response and peak handling capability of a modular converter can eliminate the need for a discrete low-voltage battery altogether (Figure 1). By converting directly from the high-voltage traction battery, modules can support auxiliary loads, even during start up or recovery events, without relying on a secondary power source or buffer capacitor bank. This reduces mass, BOM count, and design validation effort.

Figure 1: The characteristics of Sine Amplitude Converter (SAC™) modules create a path forward to operating 48V automotive loads without the need for a dedicated battery.

And these benefits scale. The same modular building blocks can support a range of vehicle classes, from compact passenger cars to heavy-duty trucks, by paralleling units or varying mounting configurations. Standardization of the sort can simplify procurement and future-proof the platform so that, as power demands increase or architectures evolve, the underlying power delivery system re-mains adaptable.

Conventional DC-DC converter architectures in automotive applications typically follow a multi-stage design, often using cascaded buck or boost regulators with output LC filtering and software-controlled switching. These designs rely on closed-loop feedback systems that monitor output voltage or current and adjust pulse width or switching frequency accordingly. While effective in regulating steady-state output, these control loops inherently limit the converter’s bandwidth and introduce unwanted latency between the load demand and the converter‘s response.

This latency becomes especially problematic when supporting fast-changing, high-current loads. The presence of output inductors and capacitors, necessary to maintain voltage stability in the face of slower feedback, imposes a physical limit on the di/dt. As a result, these converters cannot quickly supply the current surges required by inductive loads like electric power steering or active suspension actuators. The lag can compromise the performance of time-sensitive subsystems and, in extreme cases, lead to under performance or system faults. This challenge results in having to add batteries or supercapacitors to the system in order to address the latency issue.

Another fundamental limitation is the relationship between peak and continuous power. In most traditional designs, the converter’s peak power capacity is effectively equal to its continuous rating. This forces engineers to size the power stage for the worst-case transient, even if that peak occurs for just milliseconds. The result is an oversized converter, with unnecessary volume, mass and thermal management overhead for most of its operating life.

Finally, traditional architectures often struggle with bidirectional energy flow. Supporting regenerative or reactive loads typically requires additional circuit complexity, such as dual power paths or full H-bridge implementations. These add cost, increase board area, and introduce control challenges.

Modular power architectures offer a fundamentally different approach to the challenges of transient response, peak power handling and bidirectional operation. Such architectures integrate magnetics, control logic and thermal management into a compact, self-contained package to eliminate the need for many of the external components and interconnects that constrain traditional designs.

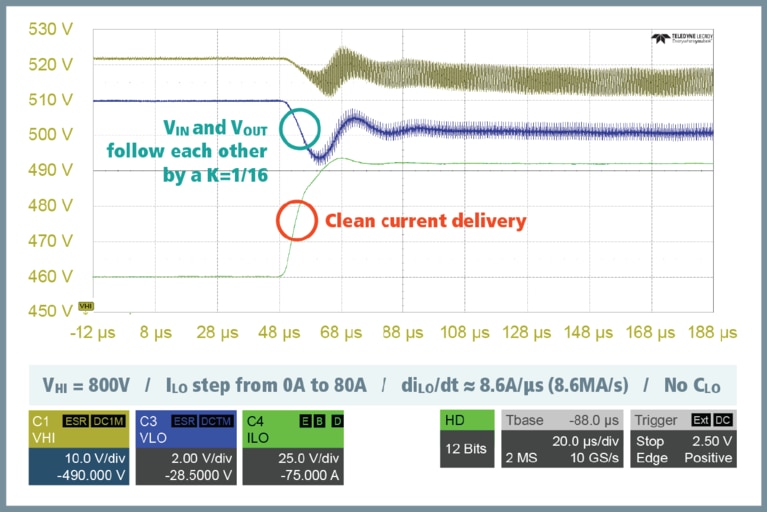

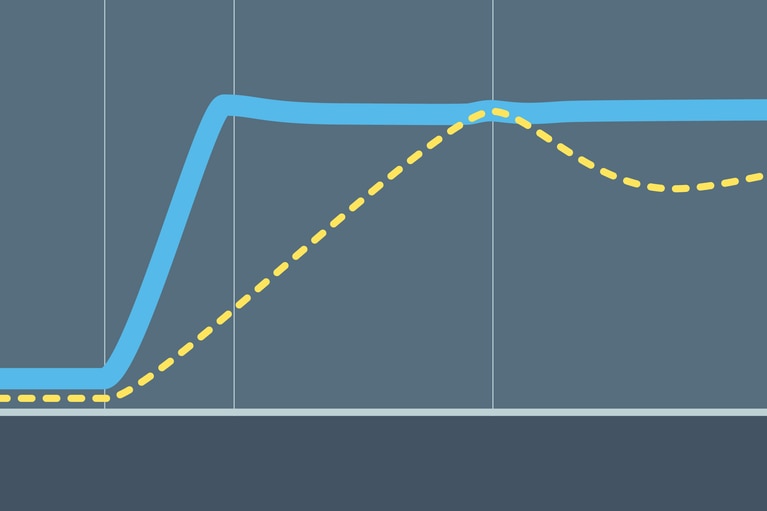

In this context, one of the major advantages lies in the physical and electrical layout. By minimizing board-level parasitics and operating at higher switching frequencies, modular converters achieve far superior transient response. When paired with topologies such as the Vicor Sine Amplitude Converter™ (SAC™) or other resonant architectures, power modules can deliver current at extremely high slew rates without relying on large output capacitors or inductors. In fact, laboratory testing has shown that SAC modules can achieve slew rates as high as 8.6 million amps per second (Figure 2). Such an architecture effectively eliminates the control loop delay and output filter lag that typically limits di/dt performance in conventional converters.

Figure 2: Laboratory testing of the Vicor BCM6135 shows that a load step transient from 0 to 80A can be met at a rate of 8.6 million amps per second.

Importantly, many SAC converters are designed to tolerate brief excursions above their continuous current ratings. This distinction between peak and continuous performance enables right-sizing, where engineers can design for nominal load conditions without over specifying the converter just to meet millisecond-scale transients. SAC modules simply deliver the peak when needed, then return to baseline operation without thermal penalties or reliability degradation.

SAC modules offer native bidirectional operation. Energy flow re-verses automatically based on load conditions, with no microcon-troller intervention, pin-level signaling or mode switching required. The architecture’s fixed-ratio, resonant operation means that SAC modules don’t explicitly distinguish between forward and reverse current, but rather respond to the voltage differential across their input and output. The result is smooth transitions at the zero-crossing point with no dead time or instability.

Active suspension is an exemplary use case for examining the limitations of traditional power architectures and the advantages of modular converters.

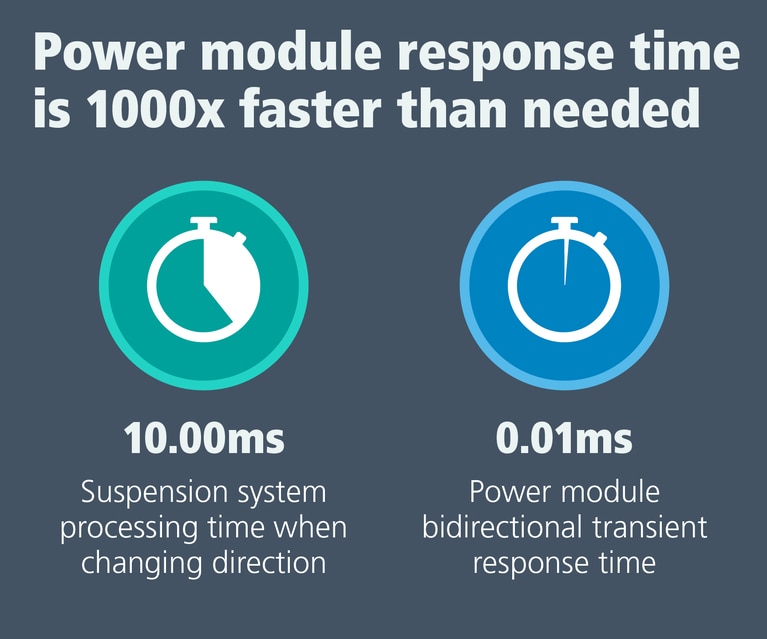

Figure 3: Today’s fastest loads demand microsecond speeds and Vicor responds in milliseconds, over a 1000x faster than needed.

Active suspension systems and regenerative loads operate bidirectionally and are both inductive and dynamic. When the vehicle encounters a bump or pothole, the suspension actuators require a rapid injection of current to generate counterforce and maintain chassis stability, and this forward energy delivery must happen within microseconds to preserve ride quality and ensure safety.

Once the road disturbance is absorbed and the suspension re-bounds, those same actuators can function as generators, returning energy to the power bus (Figure 3). This immediate reversal from sourcing to sinking current demands zero-delay bidirectionality. In traditional architectures, supporting this mode of operation often requires two distinct power paths (buck and boost), managed by an external microcontroller to coordinate the transition. Such configurations are complex, space-intensive and introduce latency and control risk at the zero-crossing (Figure 4).

In contrast, SAC-based modular converters can switch directions instantaneously to handle regenerative events as a native function of their architecture without requiring any firmware triggers, supervisory logic or discrete circuitry to enable reverse flow. The current simply changes direction, and the module accommodates it symmetrically, with no loss in performance or reliability (Figure 5).

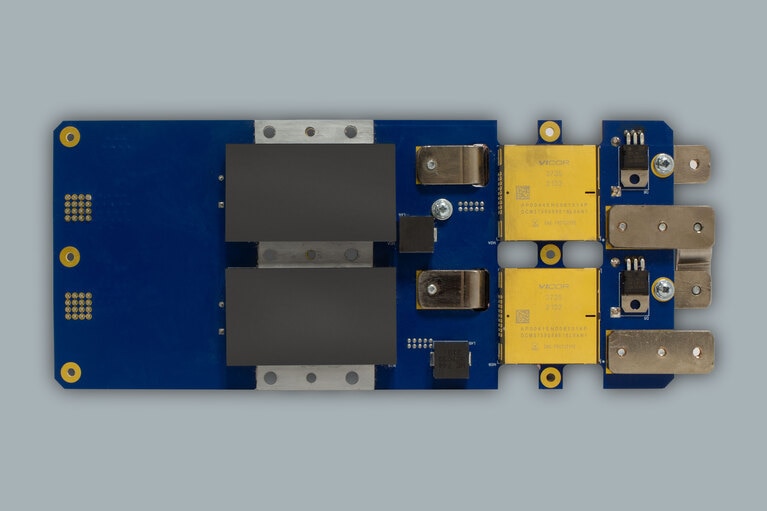

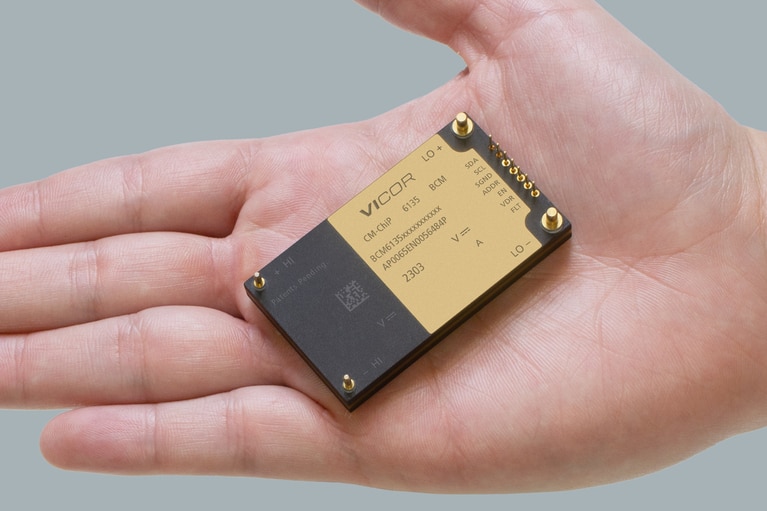

Figure 4: This 4kW 800V to 12V DC-DC converter is compact solution (23 x 10cm) for automotive applications. Vicor power modules, BCM6135 and DCM3735 support this power delivery network.

Figure 5: The active suspension example highlights the importance of bidirectionality, peak power and transient response. SAC modules offer a solution for all three that keeps system complexity at a minimum.

Figure 6: The BCM6135 is a bidirectional, fixed ratio DC-DC converter that is power dense and very efficiently converts high voltage to SELV.

As the demands on electric vehicle power systems accelerate, legacy approaches to DC-DC conversion are reaching their limits. Vicor offers a fundamentally different path forward.

As the only company in the world offering production-ready high-density power modules based on the SAC™ topology, Vicor enables EV designers to do what traditional architectures cannot: deliver instantaneous transient response, handle peak power well above continuous ratings, and switch current direction with zero delay (in milliseconds) within a compact, thermally optimized footprint. Leading automotive OEMs are already using Vicor modules in real-world production platforms (Figure 6) to replace low-voltage batteries, eliminate converter stages and meet the most aggressive power delivery requirements on the road today.

This article was originally published by Bodos Power Systems.

Roberto Cappelloni is the Director of Automotive Sales EMEA at Vicor, Italy. He has over 32 years of experience in the power conversion industry, in industrial, medical, computing and automotive market segments; that covers AC-DC and DC-DC design engineering, direct and distribution business development and sales. Roberto has a degree in Analogue and Digital Electronics from the Guglielmo Marconi Technical Institute of Jesi, Italy.

Author, Job title

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

48Vのパルス電力により、車のフロントガラスの解氷を60秒で実現

ベターフロスト社は、パルス電力を活用することで、自動車のフロントガラスの解氷を60秒足らずで実現。Vicorの電源モジュールと48V電源イノベーションについて詳しくみる。

Bidirectional power and transient speed enable scalable active suspension

Sine Amplitude Converter™ modules offer a unique combination of bidirectionality and transient response to unlock new possibilities for active suspension