Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Arcing is not a new problem for electrical engineers, but if overlooked it can have tragic consequences. Learn how overmolding is the key to simplifying arcing issues in 48V automotive power systems.

Arcing is not a new problem for electrical engineers, but if overlooked it can have tragic consequences. Earlier this year a cargo ship carrying automobiles from China to Mexico caught fire, sparked by what observers believe to be a malfunction within the vehicles’ electrical system, raising concerns around safety standards regarding EVs. The industry has relied on 12V power systems to supply power to their vehicles since the 1950s; however, as technology advances, so must the industry. With automakers requiring more power for EVs and PHEV models, the transition to 48V power systems and high-voltage batteries is inevitable.

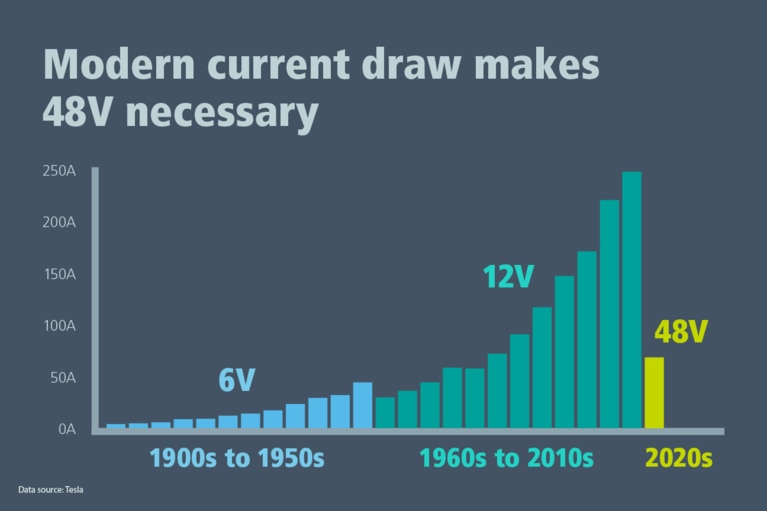

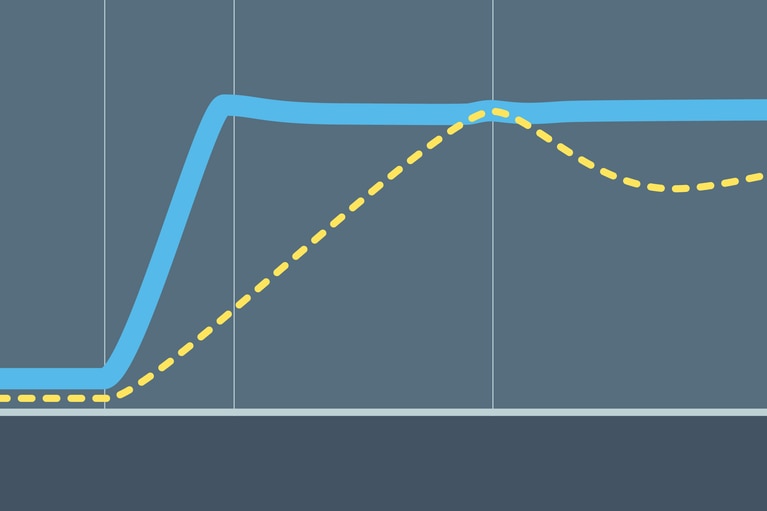

Figure 1: Conversion to a 48V bus reduces the vehicle’s total current draw from over 250A to under 75A without impacting the electrical content of the vehicle. Since 1908, the current demand in automobiles has grown exponentially with the addition of vehicle electronics. In the 1960s OEMs increased voltage from 6V to 12V, causing current to drop for the first time in 60 years. Today, most OEMs still use the 12V bus but are rapidly converting to 48V out of necessity to accommodate an influx of high-power electronics.

However, this move requires deep consideration concerning creepage and clearance safety requirements. In addition to upgrading the 48V bus, OEMs are moving to higher voltage batteries and further complicating creepage and clearance specifications (Figure 1). According to Market Report Analytics (MRA), the projected compound annual growth rate for 800V batteries will exceed 30% in the next five years. Emerging as a front runner for this new architecture, the higher voltage of an 800V battery demands greatly increased creepage and clearance distancing, generating challenges in the size and spacing of electrical systems. Higher voltage power drives increases in component spacing necessary to prevent electric breakdowns (arcing). Vehicle life expectancy is about two decades with proper creepage and clearance design, but much shorter if arcing is not properly accounted for in the design phase. Arcing can cause electric components to degrade over time possibly creating safety issues.

OEMs now face two key issues related to creepage and clearance requirements that must be addressed.

Creepage and clearance requirements are extremely important safety measures that must be accounted for in automotive applications. The requirements prevent undesired consequences resulting from electric current jumping through air gaps, better known as electrical arcing. The effects of arcing can destroy components in the vehicle, causing loss of functionality within the vehicle if severe damage is done. In vehicles with legacy 12V power systems, arcing was accounted for through modest, but very measured component rubrics, but with EVs and PHEVs beginning the transition to 48V architecture, all forms of powertrains are facing this challenge. Design requirements must adjust to ensure safety, increasing the distance between conductors to reduce the risk of arcing.

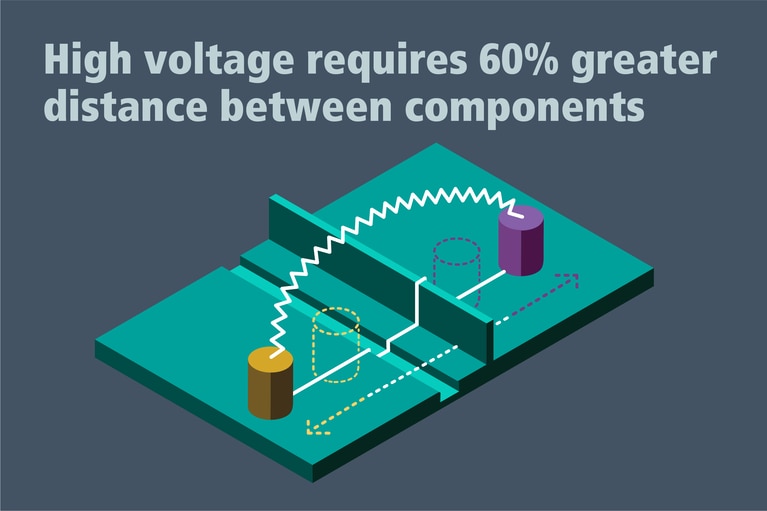

48V architecture introduces new challenges for the design engineer because of the increased voltage. Voltage increase creates higher potential for arcing. According to the IPC-2221 Standards, transitioning from a 12V architecture to one based on 48V can require upwards of a 60% increase in creepage and clearance distancing.

Figure 2: Creepage and clearance requirements are international safety measures to mitigate the risk of arcing. These requirements must be met to ensure safety and functionality. Lack of proper distancing may result in excess heat, directly damaging or compromising the power delivery network. Higher voltage requires up to 60% greater space in between components. This additional spacing can consume substantially more board space, enlarging the entire power system design which is problematic for most systems with a predefined footprint.

In 2024, The National Highway Traffic Safety Administration (NHTSA) reported 6.3 million vehicle recalls impacted by electrical systems, accounting for 33% of all recalls, highlighting the significance of component-related safety concerns. Many of these concerns can emanate from electric arcing, causing severe power system problems for OEMs. With the implementation of an 800V battery pack in a 48V architecture, the risk of arcing increases.

Traditionally, when addressing this requirement within a design, engineers allowed for adequate spacing between conductors throughout the PCB. Voltage range, material properties and intended application dictate how the standards are established. Thorough calculations are required to properly space conductive parts to ensure compliance with these safety standards. Higher voltages require further distancing.

While discrete component solutions can fulfill these requirements, their off-the-shelf components often consume a large footprint, as akin to a silver box power supply. These larger components demand up to a 60% size increase within the PDN framework (Figure 2), posing design challenge for OEMs to accommodate greater spacing needs within the same footprint. This is nearly impossible to achieve without design tradeoffs or innovating the approach.

Solving the challenge of high-voltage arcing while taking into consideration the size and space constraints is not something many discrete components can do well. What can help is a traditional packaging process called potting. Potting encapsulates components to protect them from external vulnerabilities. However, potting restricts heat dissipation, causing elevated component temperatures that accelerate material degradation, further contributing to component failures and reduced lifespan.

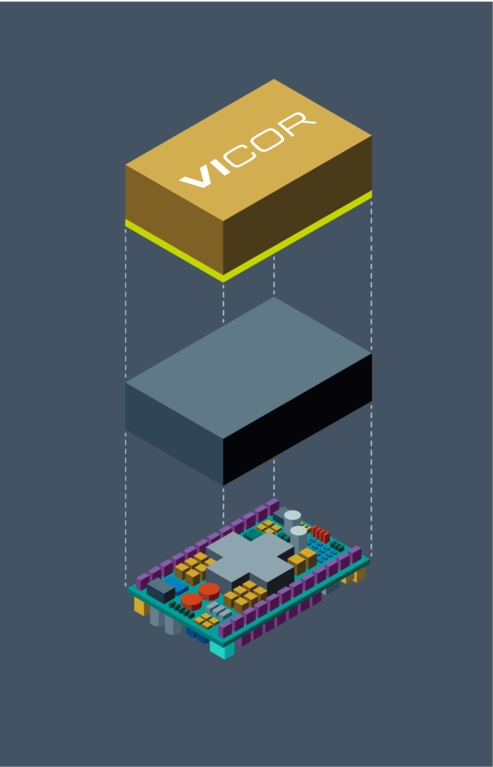

A more efficient approach to eliminate air gaps that enable arcing is through a proprietary overmolding process. With Vicor innovative packaging, the overmolding process neutralizes the risk of arcing while allowing for better heat dissipation. It also reduces size and enabling a high-density power source. The molding compound creates a solid insulation within the product, reducing creepage and clearance distances. The complete seal not only preventing pollutants from entering and causing an arc, but also compacting the size, further allowing for more space within the vehicle’s chassis to store components.

Figure 3: The Vicor ChiP™ package uses a proprietary overmolding (middle layer in gray) which completely encapsulates components. These modules are therefore free from risk of arcing, while delivering high efficiency and advanced heat dissipation to cool components more effectively.

The matrix of transitioning from a 12V to 48V power system coupled with 400/800V batteries causes increased complications for the design engineer, demanding extra caution in PCB system design standards for EV and PHEV applications. This evolution of automotive architecture creates challenges to the OEM that needs to add more spacing between components within that same footprint. From larger battery packs to various powertrain components, OEMs must look for efficient solutions in accommodating space limitations inside the vehicle’s framework.

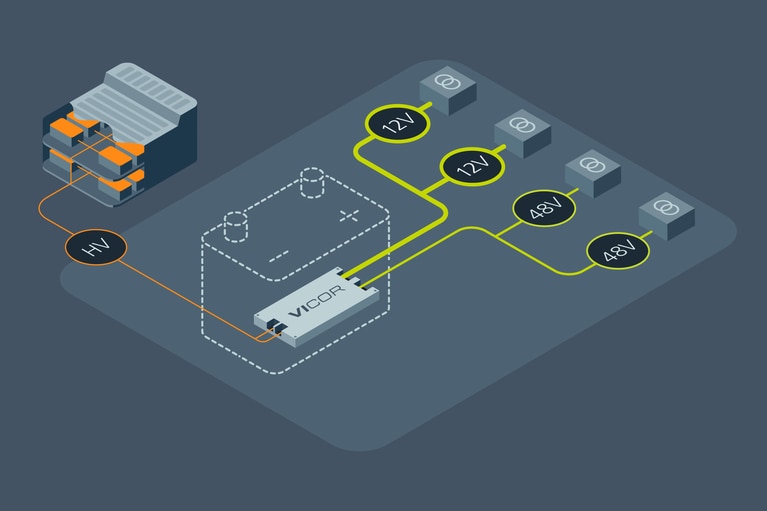

With EVs and PHEVs rapidly adopting a 48V architecture where high-voltage batteries are used, OEMs must step down the voltage as efficiently and safely as possible. Bridging these gaps requires greater component distancing. This is where many discrete module suppliers struggle. Discrete systems have trouble delivering high-power-density conversion that meets these safety requirements. For discrete solutions to adhere to proper spacing standards, they need to have a larger footprint.

This increase of vehicle package space is what OEMs are keen to avoid.

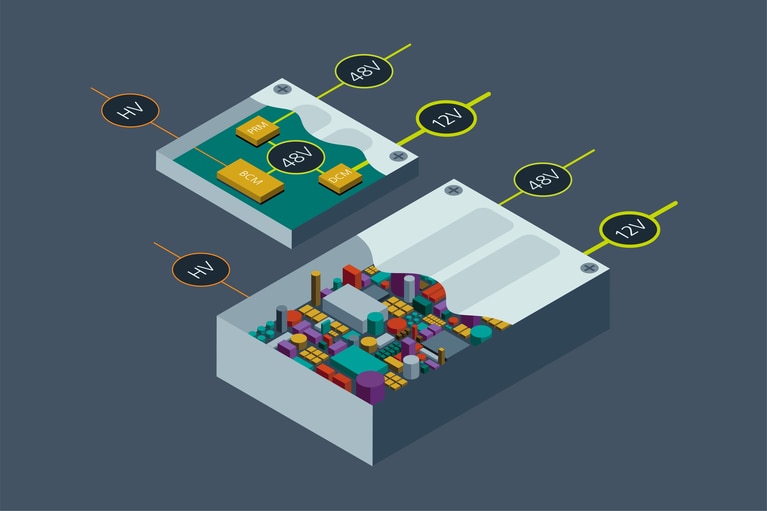

Figure 4: The ability of Vicor solutions to efficiently address creepage and clearance requirements has important residual benefits. With Vicor products, the industry can transition from a hefty silver box, filled with hundreds of components, to a smaller, lighter more efficient enclosure. The smaller power modules enable the DC-DC converters, on board charger and inverter to be housed in a small box.

Vicor innovative high-density power modules are compact and lightweight, offering a lot more flexibility in solving the issue of space especially for 400/800V battery application (Figure 3). By reducing DC-DC converter weight by as much as 50% and package volume by 60%, Vicor power modules free up space, reduce system mass and improve design efficiency. With an 80% smaller packaging size than typical bus converters, the Vicor BCM6135 has many benefits for automotive applications. It offers leading power density of 20.8kW/L and design flexibility to meet challenging creepage and clearance standards. With a peak efficiency of 98%, input range varying from 800 to 48V, and an output range of 2.4 – 55V, the BCM6135 converts high voltage to SELV (48V) very effectively.

Vicor high-performance BCM® bus converters, PRM™ regulators and DCM™ DC-DC converters help OEMs easily solve creepage and clearance challenges (Figure 4). These modules are capable of being used in parallel to scale power when needed. With high power density and compact size, these modules can be placed in tight areas. Conversely, discrete power components that are much bulkier and less efficient cannot provide the same versatility.

Figure 5: BCM®, PRM™ and DCM™ power modules effectively address safety requirements while delivering high efficiency and minimizing space consumption.

The automotive industry is in a new era of innovation that requires a fresh approach for designing for higher voltage applications such as a 400 or 800V battery pack (Figure 5). If not addressed properly arcing will hamper power designs and become a safety issue. The industry challenge is to do more (adding high voltages) but within the same space. Legacy discrete solutions are not able to achieve safe distancing for higher voltages. Therefore, it is incumbent to innovate using Vicor patented overmolded power modules. With power modules, the challenges stemming from creepage and clearance are eliminated.

From their proprietary overmolding processes to their miniaturized dimensions, Vicor high-density power modules are simplifying design challenges for creepage and clearance requirements. They are also able to deliver reliability and high efficiency while simultaneously downsizing designs and broadly eliminating arcing concerns for the OEM.

This article was originally published by Power Electronics Europe.

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

48Vのパルス電力により、車のフロントガラスの解氷を60秒で実現

ベターフロスト社は、パルス電力を活用することで、自動車のフロントガラスの解氷を60秒足らずで実現。Vicorの電源モジュールと48V電源イノベーションについて詳しくみる。

Bidirectional power and transient speed enable scalable active suspension

Sine Amplitude Converter™ modules offer a unique combination of bidirectionality and transient response to unlock new possibilities for active suspension