The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

Vicor's patented radiation-tolerant power module solutions enable Boeing to extend access to reliable high-speed broadband connectivity to the four corners of the world.

By Rob Russell, VP of Satellite Business Unit

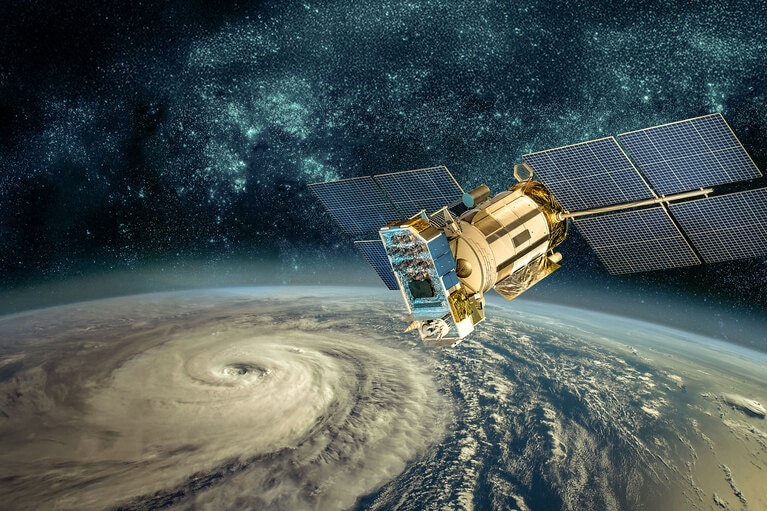

Today’s satellite communications infrastructure is insufficient to support the insatiable global demand for reliable high-speed broadband connectivity. That gap is fueling the rapid design, development and deployment of low-earth-orbit (LEO) and medium-earth-orbit (MEO) communications satellite constellations. These constellations will encircle the earth providing seamless broadband connectivity to every corner of the globe, unlike terrestrial solutions which fall far short of that promise.

Boeing is one of several OEMs approved by the FCC to design, manufacture and launch LEO and MEO satellites into orbit. The Boeing O3b project is targeted specifically at providing broadband connectivity to the “other 3 billion people” (O3b) with limited or no access to high-speed internet. A key challenge of LEO satellite designs like O3b is supplying the power needed to support power-hungry advanced communication circuitry without increasing the size and weight of the power delivery network (PDN). To add to this challenge, the power solution needs to be flexible and scalable to accommodate any unforeseen design changes or modifications in future variants. Because of the accelerated deployment schedule, fast time-to-market is essential to keep the project on schedule.

Space is a hostile and unforgiving environment, especially when it comes to electrical components, for a number of reasons including dramatic temperature variations, vibration and radiation exposure. However, the degree of radiation protection needed depends on the orbit in which the satellite will operate. Higher orbit geosynchronous (GEO) satellites require radiation-hardened (rad-hard) parts because they reside outside of the Van Allen belts and are therefore exposed to higher levels of radiation. The operational life expectancy of GEO satellites is 3 – 4x that of LEO and MEO, which increases radiation exposure as well. MEO and LEO satellites operate at much lower orbits inside the Van Allen belts, which results in lower radiation exposure; therefore, radiation tolerant parts will suffice. Some will argue that commercial-off-the-shelf (COTS) products are adequate to work in LEO satellites, but that can be a risky even with the lower radiation levels. Prudence dictates that some level of radiation protection is required to ensure proper operation and duty cycle of the satellite. After all, you can’t dispatch a service technician to fix it if that $0.25 COTS part fails in space rendering a multimillion dollar satellite inoperable.

An alternative to using COTS power solutions, the rad-tolerant modular approach to power delivery provides protection from radiation while still providing the highest power density in the industry in addition to being ultra-flexible and scalable in their architecture and implementation (Figure 1).

Figure 1: Vicor module and PDN illustration showing ease of implementation.

A close Vicor-Boeing collaboration on the O3b program resulted in a high-performing solution. The Vicor radiation-fault-tolerant DC-DC converter power modules, housed in the new Vicor plated SM-ChiP™ package, are capable of powering low-voltage ASICs of up to 300 watts from a 100V nominal power source. Immunity to single-event upsets is achieved using a redundant architecture within each module, where two identical and parallel powertrains with fault-tolerant control ICs are housed in a single high-density SM-ChiP package (Figure 2).

Figure 2: A dual powertrain, fault-tolerant design.

Advanced communication satellites require high power density and low noise. Vicor soft-switching, high-frequency ZCS/ZVS power stages reduce the power system noise floor, reducing filtering requirements, enabling signal integrity and total system performance with the requisite high level of reliability.

The complete power-source-to-point-of-load solution consists of four SM-ChiPs: the BCM3423, a 100V nominal, 300 watt K = 1/3 bus converter in a 34 x 23mm package; the PRM2919, a 33V nominal 200W regulator in a 29 x 19mm package; and two VTM2919 current multipliers, a K = 1/32 with an output of 0.8V at 150A and a K = 1/8 with an output of 3.3V at 50 amps. The solution powers the ASIC directly from the 100V power source with minimal external components and low-noise operation.

All of the modules are available in the Vicor high-density SM-ChiP package with BGA (ball grid array) connections. Operating temperature for the ChiPs is –30 to 125°C.

There are some major differences between discrete and modular power solutions. To achieve the aggressive goals of O3b a modular approach excels in several important areas. For additional details supporting the conclusions shared in the table, read the full PDN whitepaper.

Rob Russell is currently the Vice President of Satellite Business Development and has worked at Vicor Corporation for over 10 years in various strategic marketing, product marketing, and business development roles. He has over 29 years of sales and marketing experience in the electronics industry. He earned both his BSEE and MBA at the University of Massachusetts. Before Vicor, he worked for Power-One as the Vice President of Product Marketing and Director of Global Strategic Sales.

Rob Russell, VP of Satellite Business Unit

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

Delivering higher power density and low noise for New Space applications

Patented power design techniques and architectures needed to deliver optimal power and low noise for space communications applications

AI for space applications

AI has the potential to change our world with applications delivering real impact. Learn how Spacechips is powering the next generation of AI in space

Spacechips high current transponder powers on-orbit AI-driven communication

Smaller satellites with sophisticated computational capabilities is in demand. Learn how low-noise, AI-enabled power is driving creative new applications