The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

High power and current density

High efficiency

Low noise

Internal redundancy

LEO and MEO satellites are equipped with breakthrough digital payload electronics and require high-density, high-efficiency, low-noise power delivery networks (PDNs), particularly for their advanced networking ASICs. These power delivery solutions must also be tolerant to both TID (total ionizing dose) radiation and SEE (single event effects).

Vicor radiation-tolerant power modules enable the ideal Power Delivery Network (PDN) for today’s LEO and MEO satellites, providing high efficiency, high density, low-noise voltage conversion to power advanced network communication ASICs and processors to provide on orbit decision-making.

By delivering high-density power with minimal footprint, real-time processing is possible while maintaining reliable space operations.

Vicor Factorized Power Architecture allows for voltage transformation to occur as close to the processor as possible, significantly reducing distribution losses to best serve onboard processors with demanding low-voltage, high-current requirements.

Modular power delivery networks adapt to varying satellite sizes and mission profiles. This compact power design allows for seamless integration across different spacecraft and supports long-term sustainability, optimizing performance as space technology evolves.

Low noise zero-current and zero-voltage switching reduce electrical interference. Minimizing unwanted signals enhances signal integrity, allowing AI-driven satellites to process data accurately and quickly.

Single event functional interrupt (SEFI) immunity is achieved using a redundant architecture in each module, where two identical and parallel powertrains with fault-tolerant control ICs are housed in a single, high-density module. If one power path is disrupted, its protection circuits force a power-off-reset. The second seamlessly maintains full operation until the reset interval is complete and both powertrains are operating in parallel again. This redundant design strengthens long-term stability, enabling AI-driven satellites to function autonomously and efficiently in space.

Factorized Power Architecture (FPA) factorizes power from the traditional single-function DC-DC converter into two distinct functions and power modules: a pre-regulation module, a PRM and a voltage transformation module, a VTM. The power switching topologies and control systems of each module are optimized for low noise and power losses, with zero-current and zero-voltage switching. The PRM and VTM components have high density, high efficiency, low noise operation and factorization allows the VTM to be placed close to the load minimizing board losses in high current applications.

Our radiation-tolerant COTS source-to-point-of-load power delivery simplifies design by integrating the full power chain, from high-voltage bus input to low-voltage conversion, enabling faster time to market, reduced system cost, and maximized board space with compact, flight-ready components.

Satellite BCM® bus converter

Isolated fixed-ratio

Input: 100V (94 – 105V, 120V transient)

Output: 33V (31 – 35V)

Power: 400W

K factor: 1/3

Peak efficiency: 96%

33.5 x 23.1 x 7.4mm

26g

50krad, 35MeV•cm2/mg

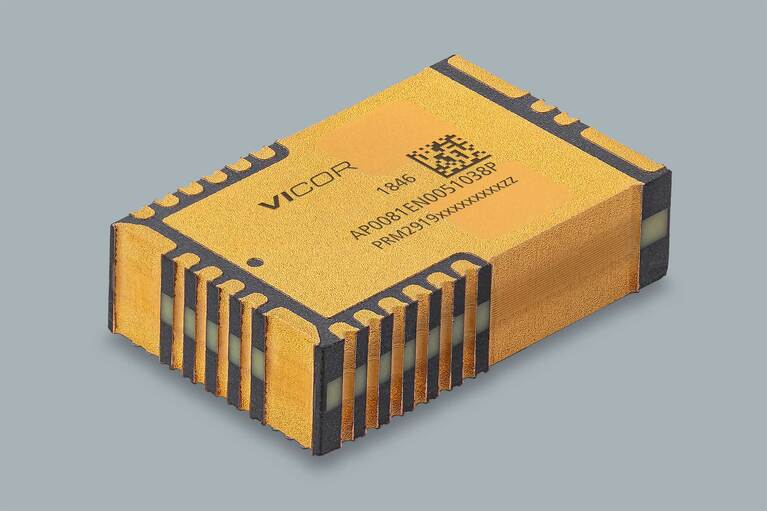

Satellite PRM™ regulator

Non-isolated regulated

Input: 33V (30 – 36V)

Output: 25V (13.4 – 35V)

Power: 200W

Current: IOUT 7.69A

Peak efficiency: 97.5%

29.2 x 19.0 x 7.4mm

18.2g

50krad, 35MeV•cm2/mg

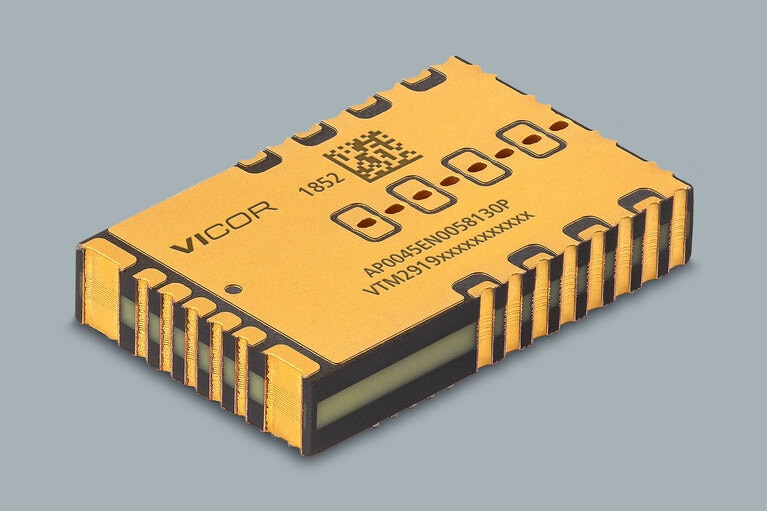

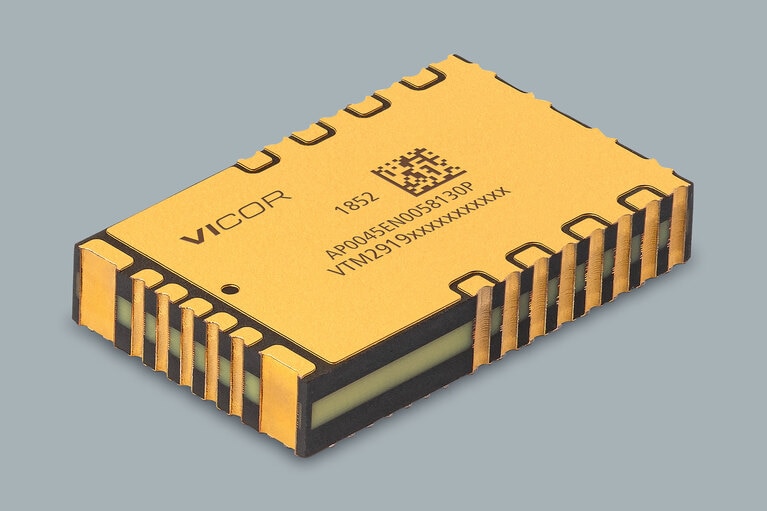

Satellite VTM™ current multiplier

Isolated fixed-ratio

Input: 25V (13.4 – 35V)

Output: 0.42 – 1.1V

Current: 150A

K factor: 1/32

Peak efficiency: 94.3%

29.2 x 19.0 x 4.9mm

13.3g

50krad, 35MeV•cm2/mg

Satellite VTM™ current multiplier

Isolated fixed-ratio

Input: 25V (16 – 32V)

Output: 2 – 3.8V

Current: 50A

K factor: 1/8

Peak efficiency: 94%

29.2 x 19.0 x 5.5mm

11g

50krad, 35MeV•cm2/mg

For over 40 years Vicor has designed and manufactured its innovative and award-winning power modules in the United States. Our fabrication facility in Andover, Massachusetts, is vertically integrated, enabling us to have greater control of the entire manufacturing lifecycle process, ensuring quality and reducing the risk of supply chain interruptions.

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

The future of standardized defense platforms using MOSA, SOSA and VPX open architectures

Delivering higher power density and low noise for New Space applications

Patented power design techniques and architectures needed to deliver optimal power and low noise for space communications applications

AI for space applications

AI has the potential to change our world with applications delivering real impact. Learn how Spacechips is powering the next generation of AI in space

Spacechips high current transponder powers on-orbit AI-driven communication

Smaller satellites with sophisticated computational capabilities is in demand. Learn how low-noise, AI-enabled power is driving creative new applications