Bidirectional power and transient speed enable scalable active suspension

Sine Amplitude Converter™ modules offer a unique combination of bidirectionality and transient response to unlock new possibilities for active suspension

Dear vicorpower.com users:

In an effort to improve the Vicor website, we will be conducting maintenance on the site Dec. 29th between 11:30 am and 2pm am EST.

Certain parts of the site may not be available during this time, specifically product pages and family matrices.

We apologize for any inconvenience and thank you for your patience.

– Vicor Web Team

Incompatibility between existing charging infrastructure and the vehicles’ primary battery (800V or 400V) is a major source of range anxiety today. Solving this problem is essential for consumer EV adoption to continue to grow. Fortunately, there are solutions.

By Haris Muhedinovic, Senior Field Application Engineer

While we are witnessing the biggest revolution in the automotive industry since the steam engine, we all have concerns about the infrastructure that it needs to sustain and penetrate well into the masses. The electric vehicle has been one of the favorite vernacular for the automotive industry, and a bunch of technology innovations are being hopped around this segment every day. The larger part of which is the infrastructure which will enable the utilization of EVs in the most coherent and effective manner. Engineers are now redefining the architecture of electric vehicles by pondering around the idea of embedding 800 volts of electrical systems that could achieve much faster charging and reduced weight and allow them to travel further between charges.

The revolution to electrify automobiles marches on as OEMs roll out new vehicles powered by 800V batteries that enable not only more powerful powertrains and higher-performing vehicles but also faster charging times. However, there are incompatibility issues for DC fast charging. To be able to charge 800V EVs at fast rates, owners must use compatible charging stations, not the 400VDC charging stations that are more prevalent today. Not only are they not compatible with these newer EVs, but they also have considerable limitations in current capability, cable thermal management, and voltage range.

This incompatibility between existing charging infrastructure and 800V vehicles is a major source of range anxiety today, and solving this problem is essential if OEMs are to continue their drive to electrify vehicles. Fortunately, there are solutions. While one solution is to expand or modify the existing network of charging stations, the surest way to eliminate consumers’ range anxiety is to make onboard chargers compatible with any DC fast-charging station.

With an electric vehicle, there are only two primary ways to boost power flowing to the battery, either by increasing the voltage or current. When the current increases, cables need to be thicker because more space is needed for electrons to move through. Increasing the voltage is a much better solution as it lowers the current and reduces cable thickness due to less resistance in the conductors as electricity flows through the cables.

Aside from graphene batteries and solid-state batteries, 800V charging architecture is the most exciting development in EV charging.

The incompatibility problem is focused on DC charging, which is commonly used for long-range driving where time and access are limited. AC charging for everyday charging is not an issue because the existing grid infrastructure AC charging is fairly convenient. This type of charging is readily accessible to people who own EVs and can charge at home (overnight) or work (daytime) where charging speed is not critical. AC charging is ideal for daily use and short-range driving, and it is the cheapest and most practical solution for daily trips up to 300km.

When people are traveling long distances, however, they need to charge quickly and in public places, such as at a highway rest stop. In those cases, they can use DC fast-charging stations. These stations require more than 50kW of power, reaching 150kW or 350kW at peak. While DC charging may be used less frequently than AC charging, it is very important to have a solid network of this type to reduce range anxiety. In 2020, the DC charging network totaled around 400,000 publicly-accessible fast chargers, with few of these supporting 800V vehicles. For example, in Europe, only 400 of 40,000 total charging stations support 800V vehicles.

This imbalance between 400V and 800V charging stations presents a significant problem as OEMs begin rolling out new 800V vehicles: the public infrastructure to charge them is inadequate.

800 volts is simply more efficient than 400 volts as it experiences less energy loss for the same amount of power consumed. It lowers the current; the lower the current, the lower the resistance (energy) loss in the conductors. With double the voltage of 400V, an electric car can charge at much faster speeds.

With 800V architectures in the EVs, vehicles are lighter, cables are thinner, wiring looms are smaller and the battery is configured to utilize power more efficiently, consequently, 800 volt unlocks more driving range.

Today’s electric vehicles have either a 400V or 800V architecture. 400V is more common because the technology is more established, but more electric vehicles are launching with 800V, like the Kia EV6 and Porsche Taycan.

By doubling the voltage by incorporating 800V in the electric vehicle architecture faster charging speeds can be unlocked without adding heat and requiring new cables and electronic components. 800-volt charging architecture slashes charging times without thicker cables, reducing weight and range. For example, in just over five minutes, the Porsche Taycan gets a 62-mile range boost and the charge time for 5% to 80% is just 22.5 minutes.

The reason 800 volts gives us faster charging is that the battery receives more power from the charger. In a 400-volt system, there is double the amount of energy loss because the current is high. The current creates resistance losses in the conductor (energy loss) so it is inefficient, especially at rapid charging speeds.

The heat generated by DC fast chargers overheats batteries and charging cables with 400V architecture, which is why charge speeds drop off a cliff after 80%.

800 volts solves this problem by changing the way the cells are connected inside the battery, allowing a lower current but a higher voltage to be used.

Make no mistake, 800 volts is great and a huge upgrade over 400 volts. However, it requires completely new engineering and design.

Broadly speaking, there are two approaches to solving DC fast-charging problem: one focuses on making changes to the charging stations, the other on making changes to the vehicle.

Expanding the DC fast-charging network of charging stations can alleviate this problem, but it may not be the most expeditious or cost-effective. There are two ways to expand the DC fast-charging network:

In contrast to expanding the charging network, onboard conversion solutions are a more holistic approach to enable 400V or 800V compatibility. This approach can be adopted much more quickly and with no capital investment in charging infrastructure.

The incompatibility between 800V batteries and 400V chargers can be solved through “battery virtualization.” With battery virtualization, the charger “sees” a 400V battery on one side of the onboard charger even while the 800V battery is connected to the other side. This approach starts from the battery voltage and adapts it to the voltage range acceptable by the charging station. (Figure 1)

Figure 1: The incompatibility between 800V batteries and 400V chargers can be solved through onboard “battery virtualization.” With battery virtualization, the charger “sees” a 400V battery on one side of the onboard charger even while the 800V battery is connected to the other side. This approach starts from the battery voltage and adapts it to the voltage range acceptable by charging station.

Vicor high-density, high-power modules can be used to implement a DC-DC converter onboard charging solution for battery virtualization without adding size, weight and design complexity.

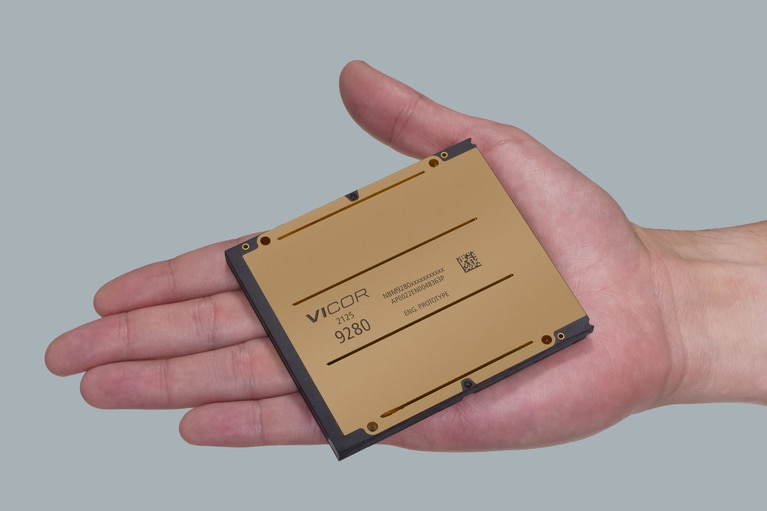

Vicor NBM™ bidirectional modules convert tens of kilowatts of power reaching 550kW/liter and 130kW/kg in power density, using power converters at least 50% smaller and lighter than discrete solutions.

Figure 2: Vicor NBM™ bidirectional modules convert tens of kilowatts of power reaching 550kW/liter and 130kW/kg in power density, using power converters at least 50% smaller and lighter than discrete solutions. Connecting a battery to one side of an NBM module will immediately virtualize a battery on the other side, dividing or multiplying the voltage or current by a constant factor.

Not only does the NBM have the capacity to offer battery virtualization for charging, but it can also integrate with the traction battery to deliver higher efficiency for low RPM driving. For example, city driving requires lower RPMs and the 800V traction inverter efficiency falls drastically by more than 15%. The NBM can be used in this ancillary manner to supply the inverter with half of the battery voltage, cutting switching losses in half and extending the driving range. This is another advantage of how an integrated, modular approach to power can optimize the power delivery network, enabling partial utilization of the DC-DC converter to maintain peak efficiency.

While charging station infrastructure will certainly expand to support the growth of EVs, expansion alone will not resolve the 400V/800V compatibility problem. The most impactful solution to reduce range anxiety is to design onboard chargers that are compatible with any DC fast charger.

This article was originally published by eletimes.

Haris Muhedinovic works with OEMs and TIERs to design and develop highest performance power solutions for most demanding automotive applications. With his interest in power electronics and electronics systems, Haris is aware of new technologies and trends in industry, which allows him to implement power solutions to meet the most demanding specifications. Haris received his MSc from the University of Sarajevo and has 7 years of experience in power electronics in design and application engineering.

Haris Muhedinovic, Senior Field Application Engineer

Bidirectional power and transient speed enable scalable active suspension

Sine Amplitude Converter™ modules offer a unique combination of bidirectionality and transient response to unlock new possibilities for active suspension

Delivering improved peak power and dynamic transient response to unlock lighter, more powerful EV architectures

With each passing year, electric vehicles (EVs) on the market are becoming increasingly reliant such as steer-by-wire, brake-by-wire and active suspension.

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products

Innovating power delivery networks

Vicor is innovating with power delivery networks. Improving end-system performance requires innovative power technologies