48Vのパルス電力により、車のフロントガラスの解氷を60秒で実現

ベターフロスト社は、パルス電力を活用することで、自動車のフロントガラスの解氷を60秒足らずで実現。Vicorの電源モジュールと48V電源イノベーションについて詳しくみる。

Following the opening of the first-ever Converter housed in Package (ChiP™) fabrication facility in Andover, Mass., Vicor has been acknowledged as a leader in Massachusetts manufacturing.

Vicor Corporation was recognized for manufacturing excellence on September 16 at Polar Park in Worcester, Mass., by the Massachusetts Manufacturing Extension Partnership (MassMEP). Following the opening of the first-ever Converter housed in Package (ChiP™) fabrication facility in Andover, Mass., Vicor has been acknowledged as a leader in Massachusetts manufacturing.

“It is a great honor to be recognized for manufacturing excellence,” said Mike McNamara, Vicor vice president of operations. “Vicor has innovated its advanced power-on-package (PoP) technology for its high-performance, high-density power modules. We feel privileged to receive this award on behalf of the many people at Vicor who made this possible.”

Thanks to the support of State Senator Barry Finegold, representing the Second Essex and Middlesex district, Vicor joins an elite group of manufacturing companies that have achieved excellence in manufacturing in recent years. This select group, which embodies the values of innovation, automation and sustainability, received a commemorative plaque in honor of their achievement.

For more than 40 years Vicor has manufactured its high-performance, high-density power modules in Andover and Lincoln, R.I. A recently completed Andover factory expansion reflects Vicor’s continued leadership in high-density power modules and underscores a continuous drive to innovate, automate and increase capacity to meet rising demand. The expansion is integral to the long-term Vicor business strategy to support high-growth markets including automotive electrification, high-performance data centers and advanced robotics.

“Our new ChiP fab is the world’s first power module foundry capable of supporting demand for high-density power modules with the scalability required by an expanding ecosystem of applications and customers,” said McNamara. “Our manufacturing process allows us to cost-effectively produce power modules with short cycle times and superior quality.”

The new, vertically-integrated ChiP fab utilizes proprietary techniques analogous to those employed by semiconductor wafer fabs. Patented processes differentiate Vicor by enabling much higher-density power-system solutions.

In May Vicor celebrated the opening of a new 90,000-square-foot, state-of-the-art manufacturing facility in Andover, Massachusetts. The power module manufacturing facility, created to support the demand coming from the fast-growing automotive electrification and data center/AI industries, is the world’s first ChiP™ (Converter-housed-in-Package) fabrication facility. The new ChiP fab sets the standard for scalable, high-volume, cost-effective and reliable power module manufacturing in the United States.

The new Vicor ChiP fab ushers in a new era of power module manufacturing. From the semiconductor-like approach to the automation and emphasis on sustainability, Vicor has been focused on excellence in manufacturing. Vicor has taken these measures not only to support customers’ demand, but also with an eye toward sustainability to remain in control of the full manufacturing process, which now includes plating under one roof.

48Vのパルス電力により、車のフロントガラスの解氷を60秒で実現

ベターフロスト社は、パルス電力を活用することで、自動車のフロントガラスの解氷を60秒足らずで実現。Vicorの電源モジュールと48V電源イノベーションについて詳しくみる。

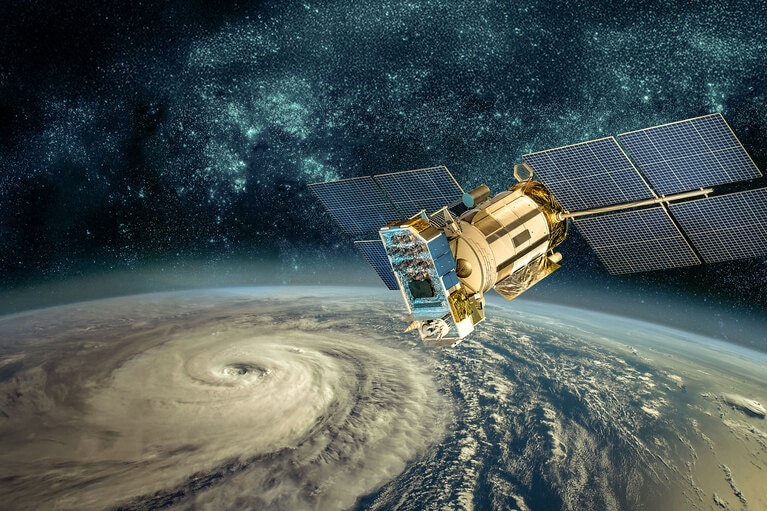

Spacechipsの大容量トランスポンダが実現する軌道上のAI搭載通信

高度な演算能力を搭載した小型人工衛星への需要が高まっています。低ノイズでAI対応の電源が、先端アプリケーションにどのように採用されているのか解説します。

クリーンな電力でハリウッドの映画セットから CO₂排出を一掃

ReVolt社は、Vicorの電源モジュールと48V配電を採用し、CO₂削減を実現したポータブル電源ユニットを開発しました。

アクティブサスペンションの長年の電力課題を解決する48Vと高電力密度のモジュール

HongfaはVicorと協業し、業界で最も高性能かつ最小サイズのアクティブサスペンション用電源システムを設計しました。