Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

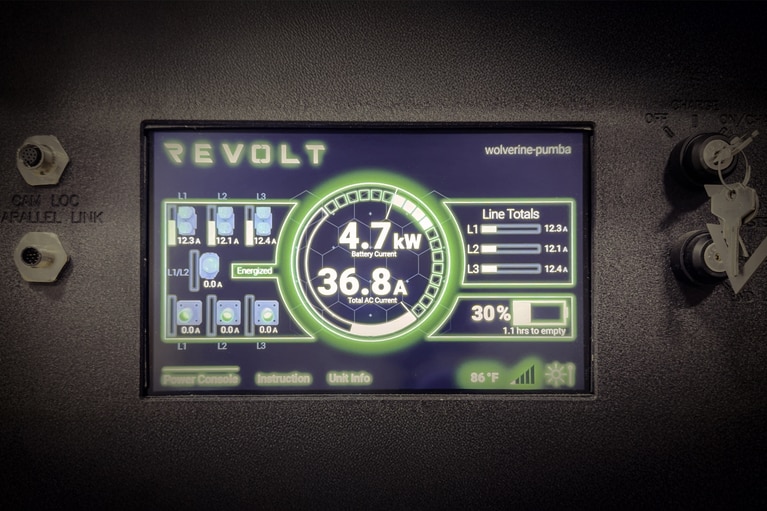

As power demands have increased, so have unwanted levels of dangerous CO₂ emissions. ReVolt has developed a better way to power film sets and studio exteriors by providing clean, mobile, and always-on electricity.

Vicor, a leading provider of high-density power solutions, is driving major changes in Hollywood. Most production companies currently rely on noisy and environmentally damaging gasoline and diesel generators to power their film sets. However, as sets become more complex—larger in size and requiring a growing array of specialized electronics—power demands have increased, as have unwanted levels of dangerous CO₂ emissions.

ReVolt Holdings, Inc. (ReVolt), a Vicor customer, has developed a better way to power film sets and studio exteriors by providing clean, mobile, and always-on electricity. ReVolt systems quietly, efficiently, and CO₂-neutrally power everything from cameras, sound and lighting equipment to special effects rigs and base camps. Founded in 2020, the startup is rapidly gaining traction, partnering with the likes of Amazon MGM Studios, Apple Studios, Sony Pictures, Warner Bros. Discovery, and its subsidiary HBO to power their sets.

A single 10kW diesel generator produces about 75dB of noise, about the same as a leaf blower, and emits the same amount of CO₂ in 12 hours as a gasoline-powered car traveling approximately 362km. Due to noise and exhaust fumes, diesel generators are typically installed 300 meters or more away from their point of use, requiring thousands of meters of expensive and cumbersome wiring.

Diesel generators also produce "dirty" current that requires additional filtering when used for sensitive digital lighting systems and motion control equipment. ReVolt charging systems, on the other hand, produce a pure sine wave profile that ensures a clean and stable power source. And they're almost completely silent, emitting noise comparable to that of a computer fan.

ReVolt has integrated its uninterruptible power technology into a growing fleet of portable vehicles. The smallest, the WeVolt, has a capacity of 17.5kWh and an output of 14kW, equivalent to a small home generator. The Mule, weighing approximately 8,555 pounds, offers a capacity of 210kWh and an output of 120kW, providing on-demand power through 480V, 208V, 240V, and 110V connections.

To ensure stable voltage levels, ReVolt has adopted Vicor's BCM® bus converters and DCM™ DC-DC converters, and more recently, PRM™ regulators.

The BCM4414 isolates and converts the 800V battery to a 35A 48V bus, to which the DCM3414 connects to regulate 24V loads. The 700W/in³ (11.05 x 3.56 x 0.94cm) BCM4414 also functions as a battery emulator, reducing the need for a conventional, bulky 48V battery. The PRM is a non-isolated buck-boost DC-DC regulator capable of converting 48V to various output voltages, with a power density greater than 2kW/in³ and 96% efficiency.

“With just one Vicor module, we can do what would normally take six or eight components to make,” said JD Schwalm, CEO of ReVolt.

Now more than ever, clean, portable energy is in high demand. As it consolidates its power concept in the film industry, ReVolt is preparing to address a variety of new applications, from providing power to disaster zones to construction sites and live events. The relationship with Vicor is helping lay the groundwork for a greener future.

This article was originally published in Italian by Elletronica In.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity