Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

The film industry has traditionally put convenience ahead of sustainability. That is coming to end as ReVolt's technology is being quickly adopted by all major movie producers to power sets and eliminate emissions.

The film business has traditionally put convenience ahead of sustainability, using portable diesel generators to power the huge electrical systems needed for modern film production. These combustion-based power sources are now common in Hollywood productions, powering everything from digital cameras and luminous arrays to advanced motion control equipment and basecamp facilities.

But this reliance is becoming more and more harmful to the environment. Time Magazine says that a large film production complex releases as much carbon dioxide as 650 homes in the United States do in a year. This shocking number has led to a complete rethinking of how the entertainment industry generates power.

In an exclusive interview with Power Electronics News, JD Schwalm, Founder & CEO at Revolt Holdings, Inc., shares the groundbreaking technology they have developed, which is causing a sea change in how the film industry powers local and remote sets.

The noise and pollution from regular diesel generators are problems that go beyond just environmental issues. A 10-kW diesel generator makes about 75dB of background noise, which is about the same as the sound of a leaf blower. It also releases CO2 equal to that of a gasoline-powered car driving 225 miles in 12 hours.

Because of noise and air pollution, generators must be placed more than 1,000 feet away from active filming locations. This requires a lot of cable infrastructure, which adds to the cost of materials, copper losses, and labor-intensive installation procedures.

ReVolt has come up with a new idea: turning the film set into a DC microgrid that can be moved around on mobile platforms. J.D. Schwalm started the company in 2020, and it has quickly formed collaborations with top entertainment companies such as Amazon MGM Studios, Apple Studios, Sony Pictures, Warner Bros. Discovery, and HBO, which is a division of Warner Bros. Discovery.

ReVolt’s mobile power platforms come in a range of sizes to meet different manufacturing needs. The small WeVolt (Figure 1) unit has 17.5kWh of storage space and 14kW of continuous output power. This makes it comparable to a residential-scale generator for specific rigging applications.

Figure 1: ReVolt’s WeVolt mobile power solution.

The Mule platform (Figure 2) is much bigger and heavier than the other platforms. It weighs 8,500 pounds, can store 210kWh of energy, and delivers 120kW of electricity continuously at four different voltages: 480V, 208V, 240V, and 110V.

This flexible output design lets you move around various trailer-mounted generators that would otherwise be the main electrical infrastructure for production facilities on the backlot and in other locations.

Figure 2: The Mule battery unit from ReVolt.

The major technical innovation that sets ReVolt’s technology apart is its proprietary ability to charge and discharge at the same time while still providing power to loads that change. This solves a problem that has always existed for battery-based power systems.

If you kept refueling them, regular diesel generators could theoretically run forever. No battery system could do the same thing. ReVolt got two patents in 2024 for finding a way around this problem, and it has three more patent applications pending.

When asked about the topological and control mechanisms that allow this bidirectional power flow to happen at the same time under very different loading situations, Schwalm said, “Our battery management system keeps an eye on cell parameters.” A huge DC battery pack powers a collection of inverters that are connected in parallel and create a grid. These inverters deliver stable, utility-grade, three-phase output power to the loads. Another set of inverters that are connected in parallel and powered by a separate battery pack with the same control features spreads the load and sends more energy to the battery pack.

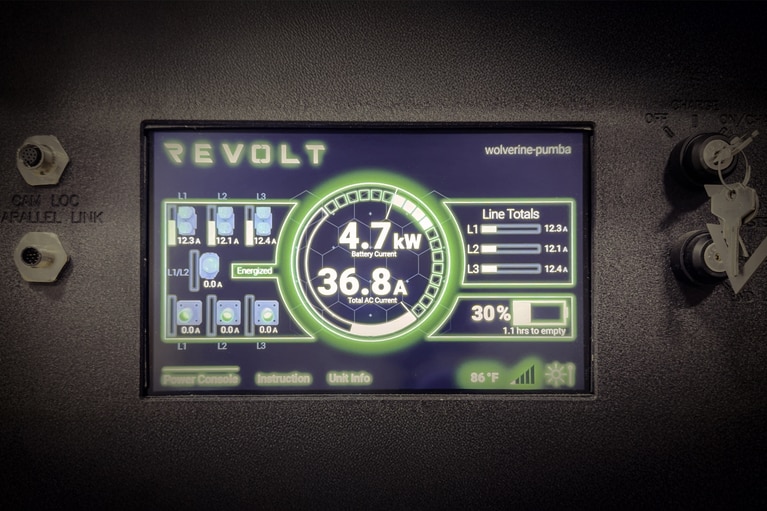

The system has advanced monitoring features that work on different levels. “Each inverter keeps an eye on the DC bus voltage and current, as well as the voltage, current, phase angle, and power factor of the three-phase AC demand,” Schwalm said. “A separate modular power meter measures the output voltage, current, and phase angle for each leg, as well as the current in the neutral leg. A custom-designed energy management system [EMS] controls and keeps an eye on each part through CAN bus, Modbus, and Ethernet”, Schwalm said.

The quality of the electrical power that is transmitted to sensitive film equipment is a very important performance metric. Diesel generators naturally create “dirty” power output that is uneven. This means that extra filtration infrastructure is needed before digital lighting controllers and motion control systems. ReVolt’s battery-electric architecture makes pure sinusoidal waveforms with steady voltage characteristics; therefore, these conditioning needs are no longer necessary.

Schwalm said, “We use three-phase filter modules to protect against loads that create harmonics”. This is in reference to the methods used to filter and control the output to keep it stable under changing loads. The system can tell when three-phase line connections are imbalanced, the neutral current is too high, or the power factor is too low. It will warn operators when these things are close to their limits.

“Our EMS uses closed-loop voltage control to tell the inverters to change the voltage based on the load,” Schwalm said. This makes sure there are no dips or spikes, which are handled by a rapid PID control algorithm.

Vicor’s high-density power conversion modules make it possible to translate ReVolt’s 800-V traction battery architecture into the different voltage needs of film production equipment. The system uses BCM® bus converters, DCM™ isolated converters, and PRM™ regulators to send voltage levels from the high-voltage direct-current backbone to low-voltage rails that are very well-controlled.

The BCM4414 module (Figure 3) does the first step of changing the voltage. It changes and separates the 800-V battery link into a distribution bus that can give 35A at about 48V. It does all of this in a small, 4.35 × 1.4 × 0.37-inch VIA™ package with a 770-W/in.3 power density. This module also acts as a battery emulator for the 48-V domain, which lets ReVolt reduce the weight of the auxiliary battery without affecting how quickly it responds to changes.

Figure 3: The BCM4414 bus converter module.

DCM modules downstream handle 24-V loads, while PRM non-isolated buck-boost regulators create point-of-use voltage setpoints with efficiency close to 96%, which greatly lowers the need for thermal dissipation.

When asked what specific benefits Vicor modules had over other options, Schwalm said, “Customer support and Vicor technical electrical engineering help were very helpful.” It was evident that these gadgets had an advantage because they were very efficient and small. “We didn’t need to run the devices in parallel, but we do run them in series,” he added. “Our thermal management technology keeps these units cool.”

Figure 4: The BCM4414 converts and isolates 800V into 48V at a 35A bus, which the DCM3414 taps off to regulate 24V loads. The BCM4414 also serves as a battery emulator, reducing the need for a bulky 48V battery .

When electrical systems are used to their full potential in very hot or cold outside conditions, such as when they are exposed to direct sunlight in the desert, they need advanced thermal management techniques. ReVolt makes its own battery modules with cellular layouts that are best for cooling. “We make our own battery modules by putting cells together in a way that maximizes cooling with forced air from speed-controlled fan arrays,” Schwalm said. “Airflow is directed through custom-designed channels in each battery assembly.”

“The thermal monitoring system has several temperature zones,” he added. “We keep an eye on the temperatures inside the cells, the inverter, the power stage, and the Mule itself. Operators can check on the system’s vital signs in real time from their phones or our web portal, which lets them keep an eye on things all the time. The system is designed to work at full load even in direct sunlight on a hot desert day.” Schwalm underscored that the system can keep its rated performance even when the environment is at its worst.

ReVolt’s choice of electrochemical storage technology has changed over time due to operating experience and supply chain issues. The company first used nickel-manganese-cobalt (NMC) chemistry to make lithium-ion batteries but switched to lithium iron phosphate (LFP) formulations. “We started with lithium-ion NMC chemistry and got great results, but we switched to lithium iron phosphate because of problems with the supply chain and buying things,” Schwalm said. “LFP has done better in thermal management and longevity.”

The modular system architecture makes it easy to quickly find and replace parts that aren’t working well. “We use a modular system architecture,” he said. “Our EMS makes it easy to find modules that are broken or not working as well as they should. All of the main parts of the system are made to be easily swapped out, repaired, or replaced with little downtime.”

Looking ahead to future technical advances, Schwalm said, “The ReVolt rental program lets us keep our platforms on the cutting edge by letting us upgrade systems as next-generation chemistries like solid-state become commercially viable.”

The difference in sound between ReVolt’s battery-electric platforms and regular diesel generators changes the way equipment is placed. ReVolt units can be placed next to powered equipment because they make only “computer fan” sounds, but diesel units need to be placed around the same distance as a football field to keep their 75-dB output outside of the acoustic environment. This closeness greatly cuts down on the amount of cable infrastructure needed, the amount of resistive losses, the number of connectors needed, and the amount of manpower needed to install the system, all while making the system work better overall.

ReVolt’s first commercial entry has been focused on film production, but the basic benefits of portable, clean, and continuous power distribution can be used in many other ways.

The company sees chances to grow in areas that deal with natural disasters, construction sites, healthcare facilities, and live events. As the world puts increasing emphasis on electrification and sustainable power generation, ReVolt’s modular architecture puts the technology at the crossroads of several growing market segments. This could change how mobile power is delivered across a wide range of industries while greatly lowering carbon emissions and environmental impact.

This article was originally published by Power Electronics News.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity