Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

Film production has long depended on portable diesel generators to feed lighting, cameras, motion control, comms, and basecamps. Sets are getting more electrically intensive, and using gensets can lead to engineering constraints and environmental problems.

Film production has long depended on portable diesel generators to feed lighting, cameras, motion control, comms, and basecamps. Sets are getting more electrically intensive, and using gensets can lead to engineering constraints and environmental problems. Noise can dictate equipment placement, and exhaust may limit airflow and working distance. The variable “dirty” output forces extra filtering ahead of sensitive loads.

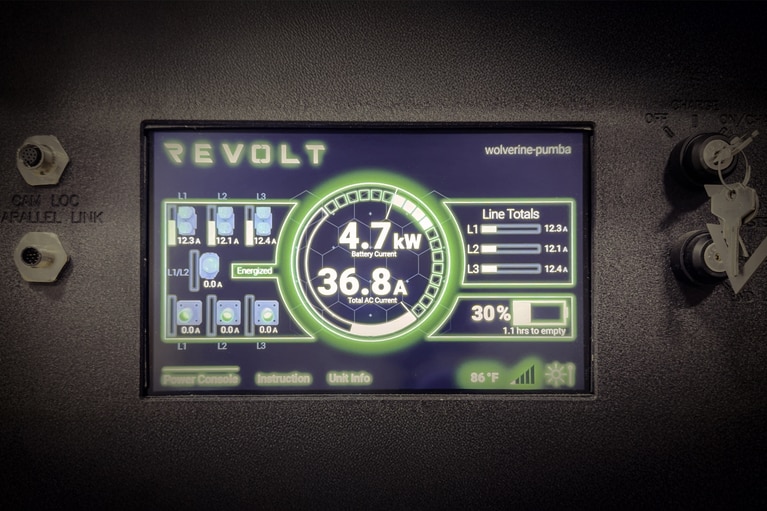

ReVolt Holdings’ battery-electric alternative reframes the movie set as a DC microgrid on wheels, pairing an 800V traction-style pack with modular power conversion to present clean AC at multiple voltages without the decibel and emissions penalties of combustion.

Figure 1: The portable systems power cameras, sound, lighting, and more on a movie set.

ReVolt’s fleet spans compact units for specialty rigs to high-capacity platforms sized for backlot and on-location basecamps. The WeVolt unit targets small-footprint three-phase loads, while the larger Mule class delivers 120kW continuous with pack capacities configured into the hundreds of kilowatt-hours and native outlets at 480V, 208V, 240V, and 120V. This is enough to displace a yard of trailerized gensets for core set infrastructure.

The system is designed for continuous power while charging, so crews can backfill energy from the grid or renewable sources without interrupting supply. ReVolt reports fielded systems powering cameras, lighting, SFX, and basecamps for major studios with near-silent acoustics and zero on-site CO2.

Figure 2: The WeVolt is the ReVolt’s smallest option for industrial-grade three-phase power.

In operation, eliminating generator noise and fumes allows units to move closer to the action, shrinks cable runs, and reduces the associated copper losses, connectors, and labor. Industry groups have pushed this transition for years to cut emissions and acoustic impact on location. Electrified sets are gaining traction as the technology matures.

Under the hood, ReVolt uses the Vicor BCM® bus converters, DCM™ isolated converters, and PRM™ regulators to translate an 800V battery backbone into the low-voltage rails and tightly regulated outputs that film equipment requires. A BCM4414 stages down the HVDC link to an isolated ~48V distribution bus (up to 35A in a 4.35 x 1.4 x 0.37in VIA™ module), providing the high power density and galvanic isolation needed for safe, compact packaging.

Downstream, DCM modules service 24V loads, while PRM non-isolated buck-boost regulators generate point-of-use setpoints with reported efficiencies to ~96%, minimizing thermal burden and enabling the “no-heatsink” approach ReVolt emphasizes across the platform. In some configurations, the BCM acts as a battery emulator for the 48V domain, allowing ReVolt to trim auxiliary pack mass without compromising ride-through or transient behavior.

The most immediate difference crews notice is acoustic. Where a ~10kW diesel is typically sited a football field away to keep ~75dB out of the mix, ReVolt units operate at “computer-fan” levels beside the gear they power. The company also identifies pure-sine output and stable voltage advantages for digital lighting and motion-control rigs that would otherwise need additional filtering behind a genset.

From a carbon and air-toxics standpoint, moving loads off nonroad diesel engines cuts not just CO2 but NOX and particulates at the worksite, aligning with studio sustainability targets and permitting requirements.

This article was originally published by EE Power.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity