Tesla Cybertruck will eliminate 12V electrical components

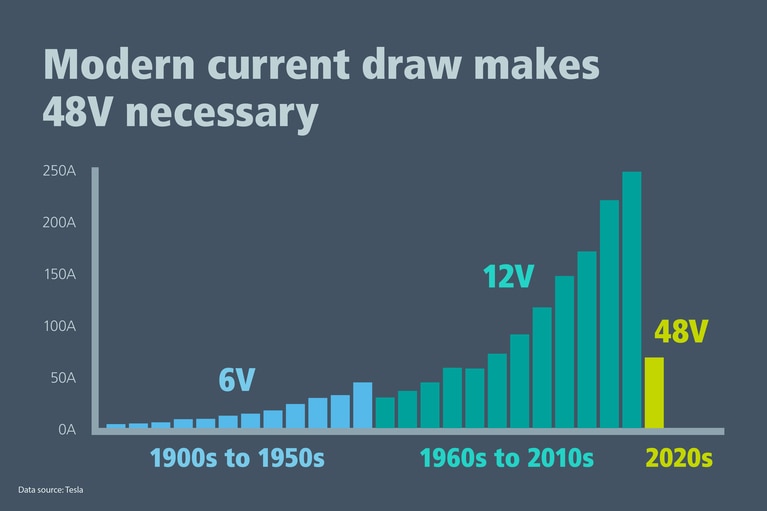

Engineers have consistently predicted that cars would shift from 12V electrical systems to 48V systems for two decades. But cost and inertia have kept 12V electrics in place, with the occasional targeted application of 48V power in high-current applications.

But the age of 12V-free vehicles is finally imminent, according to Tesla's vice president of hardware engineering, Pete Bannon. “One of the changes that we're looking to make right now is to change something that's been steady for the last 60 years: 12 volts,” he said at Tesla’s annual Investor Day conference.

There is good reason to make the switch, Bannon explained. “For 60 years the demand for power in the car has been steadily increasing to the point where we now have to have pretty large wires to drive over 200 amps of current around the car, which increases the mass and cost,” he said. These are the factors that have led to the longstanding expectation that the industry would shift.

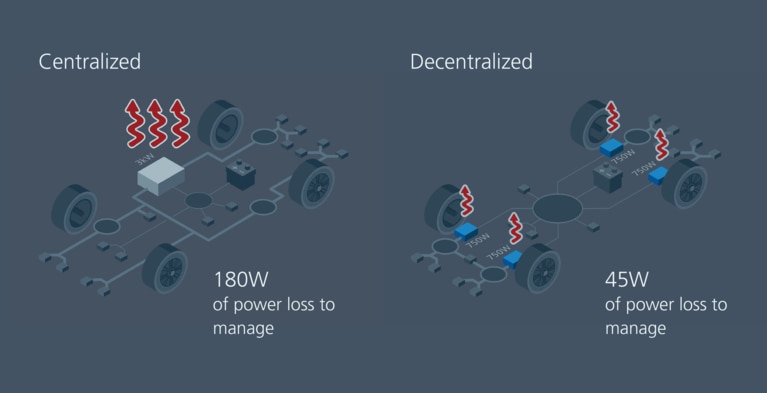

“With Cybertruck and all future Tesla platforms we'll be moving to 48V,” Bannon announced. “This reduces the current needed by a factor of four. And since power loss in the harness is resistance times the square of the current, a four-times reduction in current leads to a 16-times reduction in lost power while distributing energy in the car. That allows for smaller wires smaller e-fuses and smaller controllers. That also allows us to make the heat sinks smaller or in many cases remove [them] completely, benefiting the car in terms of mass and weight.”

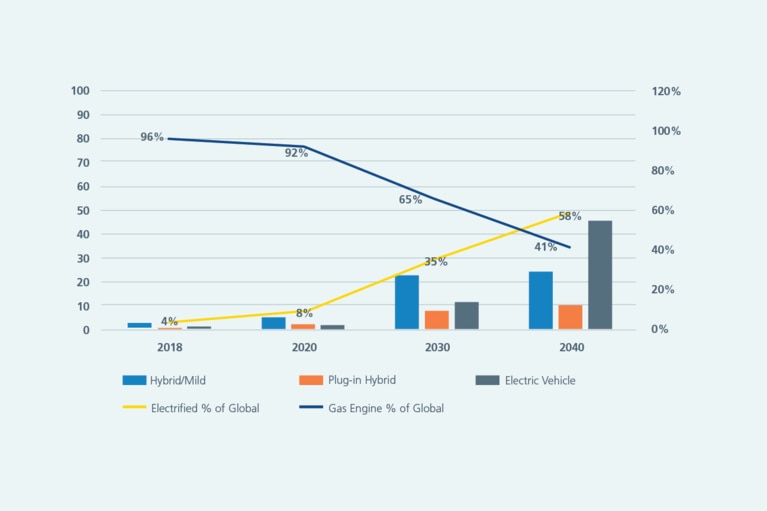

So far, the application of 48V technology has been limited. “48V systems have been around for a few years now, powering the starter-alternator in mild hybrids and other high-power accessories like active suspension and power steering,” notes Mike Austin, senior research analyst for electric vehicles at Guidehouse. “Like Tesla said in the presentation, the higher voltage allows for lower current and thinner wires, which saves weight and cost.”

Figure 1: The future of low-voltage architecture (Cybertruck, Optimus and future vehicles – all 48V).

However, while a simplified wiring harness is cheaper and easier to install, the 48-volt components are more expensive, which has been a key factor. “It hasn’t proliferated more so far mostly because of cost,” Austin explains. “A 48V battery and controller are more expensive than an everyday 12V starter and battery.”

The fragility of the filaments in incandescent bulbs was another long-time obstacle, as the number of bulbs throughout vehicles seemed to make the idea of eliminating 12V systems a headache. However, LED lighting already includes circuitry to adapt the voltage to the low levels used by the LED lights, which means they should be able to work with 48 volts as they do with 12V systems, said Greg Green director of automotive marketing at Vicor, a company that specializes in power modules.

Figure 2: Managing power loss with a traditional converter at 94 percent efficiency.

And the cost side of the equation can be addressed in EVs by the complete elimination of the low-voltage battery. Instead, these cars can employ a power converter that steps down the high-voltage from the traction battery to power on-board systems. “It’s easier with an EV, where all you need to do is convert the voltage from the drive battery,” says Austin. “If Tesla plans to use 48 volts for all the low-voltage in its cars, there will be savings in terms of complexity, weight, and materials.”

That’s exactly the scenario Vicor is promoting. “In the transition from internal combustion cars built around 12V alternators, 48-volt is something you have to pay extra to get. With EVs, the transition down to 48 volts is kind of natural.”

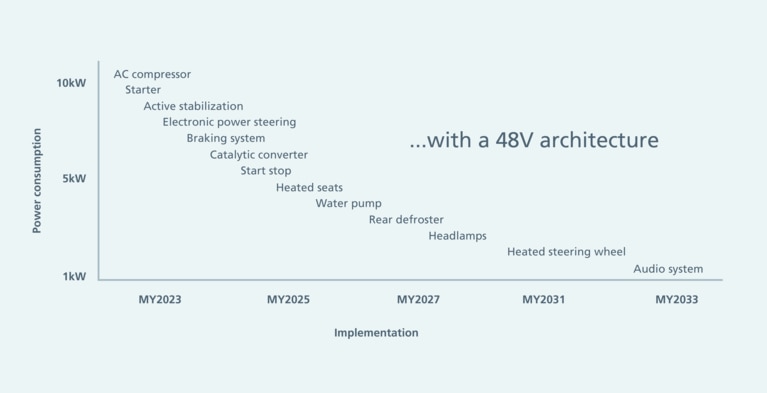

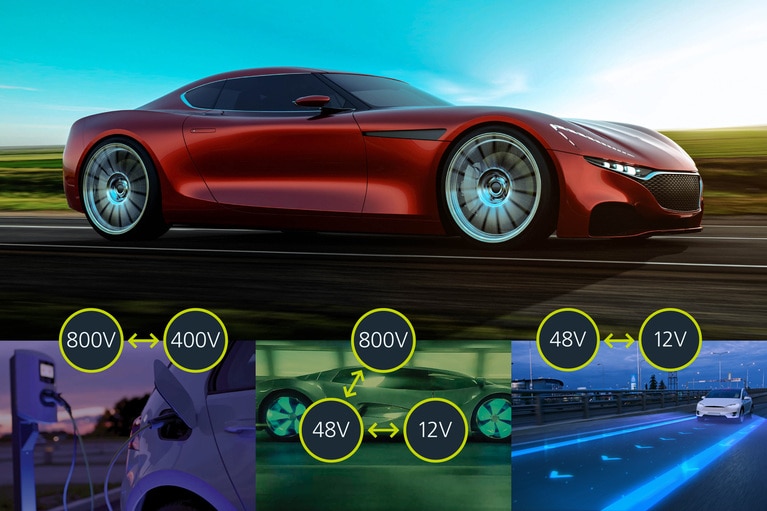

Figure 3: Systems moving from an overloaded 12V system to 48V.

Not only do they benefit from the reduced weight and size of the wiring harness, but some of the devices powered by the system also benefit, according to Green. “Compressors and pumps work more efficiently at 48 volts than at 12 volts,” he says. “It is a double bonus.”

The trick has been to develop power converters that deliver power on demand with the stability of a battery. Vicor says it has solved that challenge. “We’ve been working with customers developing very compact DC-DC converters that convert the high-voltage battery down to 48V,” says Green. And for any legacy 12V devices, Vicor offers additional modules that break the voltage down again from 48V to 12V.

Tesla announcing that delivery of a technology is imminent is one thing; the company actually delivering that thing is another. So it remains to be seen when production Cybertrucks actually reach retail customers in volume.

Figure 4: Global forecast by powertrain type.

But no matter what Tesla does, other carmakers have production plans in place for 48V vehicles too, says Green. Vicor’s launch customer will make an announcement of a new model later this year for delivery in 2023 or early 2024, he says. Additional customers are slated to follow in 2025 and 2026, with 12V systems tapering off over the next decade.

“Forty-eight volts is the future for low voltage design at Tesla and likely the rest of the industry in due course,” concluded Bannon.