Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

By Phil Davies, VP Global Sales & Marketing and Tom Curatolo, Senior Principal Apps Engineering

Power delivery to the various points‑of‑load within a system is done via a Power Delivery Network,commonly referred to as the PDN. The PDN consists of cables, bus bars, connectors, circuit board copper power planes, power converters and regulators. The performance of a PDN is measured in terms of power loss, size, weight and cost. Governing PDN performance is its overall architecture, such as the use of AC or DC voltage distribution, specific voltage levels and when and how many times the network needs voltage conversion and regulation. This white paper discusses a particular type of DC‑DC converter, the fixed‑ratio converter (sometimes referred to as a bus converter), and why power system designers should consider it an essential part of the power delivery architecture, particularly for high‑power systems.

Power systems engineers spend a great deal of time architecting and optimizing power delivery networks to deliver high system performance and reliability. If the system load power is high, designing bulk power delivery with a high voltage reduces the current (P = I • V) and therefore the size, weight and cost (cables, bus bars, connectors, motherboard copper power planes) of the PDN (PLOSS = I2R). Architecting the system to maximize the length of the high‑voltage runs before converting down to lower voltages and higher currents is also a big advantage. However, bringing a high‑voltage and high‑power PDN close to the load requires a DC‑DC converter with high efficiency and power density. If safety is a concern as in mobility applications (automobiles), converting down to a SELV (safety extra low voltage) level PDN from a high voltage with high efficiency and power density is critical to overall system performance.

DC‑DC converters can be designed with many different architectures and topologies but fundamentally they are either regulated or non‑regulated, isolated or non‑isolated. DC‑DC converters with no regulation are called fixed‑ratio converters and they typically have higher efficiency than other converters when operating with a wide input to output voltage ratio. Higher efficiency can result in higher power density and easier thermal management due to lower power losses. However, because they are not regulated, fixed‑ratio converters can be more demanding on downstream regulators if their input voltage has a wide operating range. Recent improvements in the efficiency of DC‑DC regulators when operating over wider input voltage ranges have made the use of fixed‑ratio converters possible. With higher bulk‑power DC voltage levels and intermediate bus voltage levels becoming more popular, the use of fixed‑ratio or bus converters can offer significant performance and system cost advantages.

A fixed‑ratio converter is a DC‑DC converter whose output voltage is a fixed fraction of the input voltage. The converter provides no regulation and the input‑to‑output voltage range is defined by the “turns ratio” of the device. This turns ratio, referred to as the K factor, is expressed as a fraction relative to its voltage step‑down capability. K factors can range from K = 1 to as low as K = 1/72in point‑of‑load converters.

Typical inputs are low voltage (LV), high voltage (HV) and ultra‑high voltage (UHV). K factors are then selected based on the desired PDN voltage and PoL design.

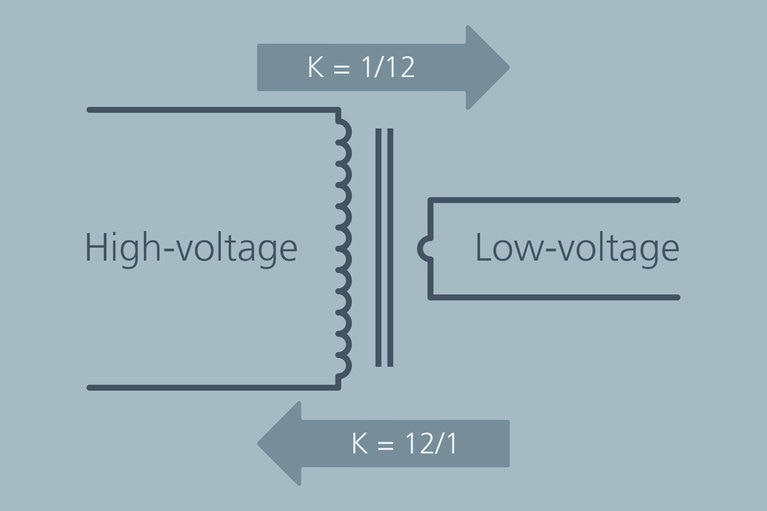

Fixed‑ratio converters can be isolated or non‑isolated and, as is the case with Vicor converters, capable of bidirectional power flow and voltage conversion. For example, a K 1/12 fixed‑ratio converter with bidirectional capability can be operated as a boost converter with a K of 12/1.

Figure 1: Step‑up and step‑down K factors of a bidirectional fixed‑ratio converter.

Additional design flexibilities offered by fixed‑ratio converters include ease of paralleling to meet higher power demands and connecting converter outputs in series to provide higher output voltages, effectively changing the K factor by N • K (N = number of bus converters).

Figure 2: BCM converters in a parallel array.

Figure 3: BCMs with outputs connected in series for higher output voltage.

In a “hard switched” converter the output power is proportional to the converter duty cycle, which can be varied to provide more or less power from the secondary. This category of circuits is called Pulse Width Modulated or PWM converters. The switching frequency is practically limited to several hundred kHz by the high levels of power dissipated by the switching devices. Despite its shortcomings, the PWM converter is superior to linear regulators in applications where the input/output voltage ratio was large; the PWM converter started the movement to the widespread use of DC‑DC converters.

The SAC is a transformer‑based series resonant topology. Unlike regulated quasi‑resonant ZCS / ZVS converters, the Sine Amplitude Converter operates at a fixed frequency equal to the resonant frequency of the primary‑side tank circuit.

The switching FETs in the primary are locked to the natural resonant frequency of the primary and are switching at zero crossing points, eliminating power dissipation in the switches (boosting efficiency) and greatly reducing the generation of high‑order noise harmonics (requiring less filtering of the output voltage). The current in the primary resonant tank is a pure sinusoid rather than a square wave or a partially sinusoidal waveform as seen in prior generations of converters. This also contributes to reducing harmonic content and provides a much cleaner output noise spectrum.

The leakage inductance of the primary is minimized in a Sine Amplitude Converter since it is not the critical energy storage element.

The SAC can therefore operate at a much higher frequency allowing for a much smaller transformer, and increasing both power density and efficiency. The Vicor BCM operates at a frequency of several MHz; this frequency is fixed regardless of load. In response to an increased load on the secondary, the Sine Amplitude Converter reacts by increasing the amplitude of the sinusoidal current on the primary resonant tank. This in turn increases the amount of energy coupled into the secondary, countering the increased load. When the load current is reduced, the amplitude of the sinusoid decreases approaching zero under “no‑load” conditions.

The output impedance of the Vicor bus converter is extremely low, reflecting the low output impedance of the resonating tank circuit on the primary side of the transformer, which ideally presents zero impedance at its resonant frequency. This impedance is essentially flat up to approximately two‑thirds of the resonant frequency. This is approximately one half the output impedance of a conventional IBC.

The sinusoidal nature of the current in the primary leads to advantages in the electrical noise profile of the SAC. The output noise spectrum is very narrow with major components at the switching frequency and two times the switching frequency (due to the full wave rectification of the output). Output filtering is easily achieved with small high‑frequency ceramic‑type capacitance.

Vicor fixed‑ratio converter modules offer a large selection of voltage ranges, K factors, isolation or non‑isolation and bidirectional operation. There are four primary families that address different bulk power, intermediate bus and point‑of‑load conversion needs:

The Vicor Sine Amplitude Converter (SAC™) topology is used in all Vicor converter modules, enabling them to outperform competing fixed‑ratio converters in virtually every relevant metric, including conversion efficiency, power density, package profile, transient response and bandwidth.

Power delivery networks are undergoing significant changes due to the soaring power demands within many end‑markets and applications. As new features are added and performance levels advance, higher voltages are being used for power delivery as a way to reduce the physical size, weight and cost of the PDN itself.

Two markets undergoing rapid changes to their PDN architectures are automobiles and data centers. The electrification of vehicles to meet new CO2 emission standards and the move to pure electric vehicles has seen the addition of 800V, 400V and 48V conversion and regulation requirements within vehicles.

The data center market is adding 380V and 48V PDNs to support the addition of artificial intelligence (AI) and high‑performance computing. Processor steady‑state and peak current demands have been on an almost exponential rise. This dramatic increase is causing a PDN dilemma at the point‑of‑load, requiring a complete rethinking of architectures, topologies and packaging to solve the problem.

Figure 4: Power requirements are rising at a rapid rate, driven by new higher‑powered applications like AI, cloud computing and electric vehicles.

Tethered UAVs and exascale computing racks use high voltages of 800V and 380V, respectively, as a means of reducing the size, weight and cost of their bulk power cables. In the case of a tethered drone, the power cable to the drone can be over 1000 meters in length, which the drone must lift to achieve its flying height.

Exascale computing racks are approaching power levels of 100kW, which eliminates the possibility of using traditional 12V distribution. Redefining the power delivery architecture by utilizing high‑power‑density Vicor K 1/8 BCMs that can be located in close proximity to each of the server blades enables 380V DC distribution in the rack, significantly reducing the size, weight and cost of the PDN. The 380V DC is developed from the output of the front‑end three‑phase AC‑DC converter.

The bidirectional capability of these devices is also opening up new applications such as delivering power to wireless radio towers equipped with new high‑power 5G systems. In these applications the 48V SELV provided by the ground power supply is up‑converted to 384V with a K 1/8 fixed‑ratio BCM™ used in reverse to give an 8/1 step‑up conversion. This significantly reduces the size and cost of the power cable that delivers power to the 5G radio systems at the top of the tower.

In mobility applications such as electric vehicles, high‑voltage distribution is not used due to safety issues. However, high‑density, low‑weight BCMs can provide excellent options for 800V‑to‑48V or 400V‑to‑48V conversion. The 48V is SELV and can be distributed around the vehicle to significantly reduce cable size from the traditional 12‑volt PDN system.

Three‑phase AC‑DC front‑end power converters can also take advantage of the BCM’s high density and efficiency, using them for the DC‑DC conversion and isolation functions following the rectification and PFC stages of the converter.

By utilizing new Vicor 800V and 380V fixed‑ratio isolated bus converters (BCMs), with power densities up to 2735W/in3 and efficiencies up to 98% peak, power system architects are not only solving their PDN challenges but also achieving very high system performance.

Hybrid vehicle and cloud computing server applications that want to take advantage of higher‑voltage PDNs but are restricted to SELV environments can utilize the significant density, efficiency and flexibility advantages of a non‑isolated fixed‑ratio converter like the Vicor NBM. In these applications many designers need to keep their legacy 12V loads, but still require a cost‑effective and high‑performance 48V‑to‑12V converter to take full advantage of a 48V PDN.

The Vicor NBM2317 is a 1kW non‑isolated fixed‑ratio converter in a 23mm by 17mm surface‑mount ChiP™ package that provides engineers a flexible, modular, low‑noise solution. The NBM is also very scalable and can be paralleled to rapidly provide higher‑power solutions with a single qualified component.

Fixed‑ratio converters can also be used as current multipliers for low‑voltage, high‑current, point‑of‑load applications such as data center CPUs, GPUs and AI ASICs. As the input voltage is down‑converted by the turns ratio or 1/K factor, the K factor acts as the current multiplication factor as shown in the following simplified equation:

VIN • IIN = (1/K • VOUT) (K • IOUT)

If the converter is fed by a tightly regulated input device, such as a PRM in the Vicor factorized power architecture (FPA™), this provides a very efficient and high‑density 48V‑to <1V, PoL solution.

Figure 5: Factorized Power Architecture (FPA) is used when high‑current board‑mounted power is needed. Today’s higher power requirements and lower (<<1V) PoL operating voltages are straining IBA performance. The increased power and dynamic load requirements for CPUs, GPUs and AI processor applications demand that voltage regulators be located closer to the load input power pins.

The high‑density current multiplier module (either VTM or MCM) can be placed extremely close to the processor, either laterally alongside the processor or directly beneath, delivering power vertically into the processor power pins above. At 1000 amps of current a PDN resistance of 1μΩ translates to 1W of power loss. Typical PDN resistances with traditional multiphase synch buck VRs have PDN resistances of 200μΩ (200W power loss) which renders system performance unacceptable. Lateral power delivery or vertical power delivery with a Vicor current multiplier lowers the PDN resistance to 50μΩ and 5μΩ respectively.

The unique attributes of Vicor fixed‑ratio converters are enabling power systems engineers to redefine their power delivery architectures to meet the high power and performance demands of their advanced systems. High power density, efficiency and ease of paralleling, plus operational capabilities as step‑down / step‑up converters and as high‑density current multipliers at the point‑of‑load make fixed‑ratio converters one of the most flexible and highest performing DC‑DC converters. Future‑proof your power delivery architecture with Vicor fixed‑ratio converters.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power