ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

Almost everything around us is touched at some point by robots. There are robotic applications utilized in agricultural harvesting, warehouse inventory movement, campus delivery and consumer delivery. These robots are fueled by batteries, making power conversion efficiency – along with size/weight – critical. Power conversion needs become more and more challenging as load capacity, visual recognition and user functionality requirements further increase within the robotic application. This video shares how Vicor power modules support a component-based power delivery network to power motor drives and demanding CPUs. Each power module is optimized for high-efficiency, density and overall performance. Go to Vicor robotics solutions

BCM4414 fixed ratio DC-DC converter

Input: 500 – 800V

Output: 31.3 – 50.0V

Current: Up to 35A

110.6 x 35.5 x 9.4mm

NBM2317 fixed ratio DC-DC converter

Input: 38.0 – 60.0

Output: 9.5 – 15.0

Power: 60A

22.8 x 17.3 x 7.4mm

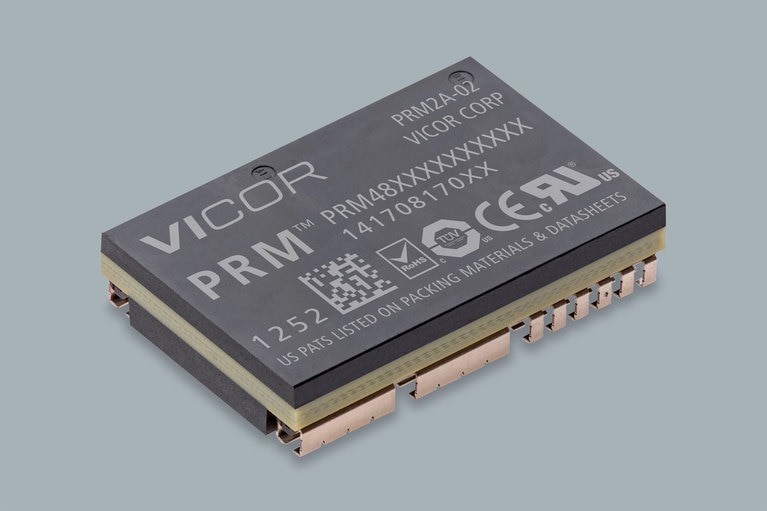

PRM high-power Buck-Boost regulator

Input: 36 – 75V

Output: 20 – 55V

Power: Up to 600W

32.5 x 22.0 x 6.3mm

DCM3623 isolated regulated DC-DC converter

Input: 9 – 154V

Output: 3.3 – 53V

Power: Up to 320W

36.38 x 22.8 x 7.26mm

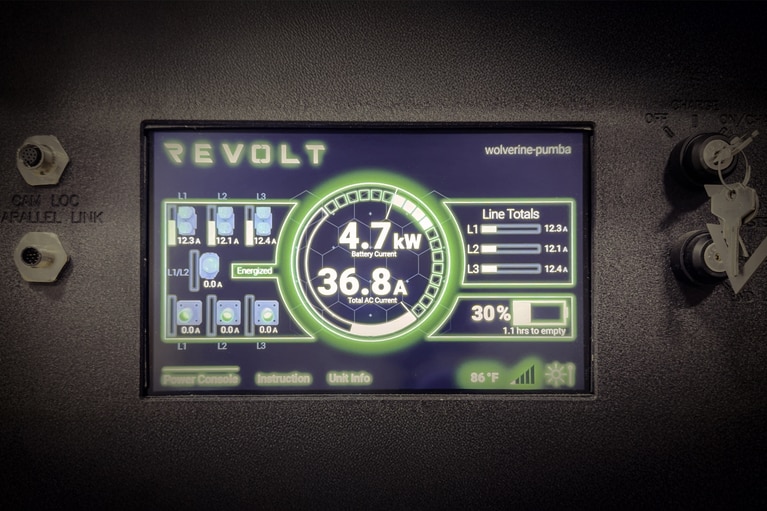

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

Current multipliers: The obvious choice for powering AI processors and other demanding applications

AI processors need to handle low-voltage, high-current demand, which can cause power system bottlenecks. Learn how current multiplication can change that

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity

Helping Hollywood fulfill its green ambitions

ReVolt is the cleaner, greener solution to the massive fossil fuel burning generators used on movie sets today. Learn how Vicor is helping ReVolt