How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity

Semiconductor manufacturers are placing greater demands on Automatic Test Equipment (ATE) companies to design test systems that will meet the ever-increasing IC demand as quickly and reliably – and with as little added cost as possible.

IC manufacturers consider Cost of Test (CoT) as a cost adder that, while required and necessary, only subtracts from product margins, requires ever increasing factory floorspace and does not improve cycle time and yield.

ATE system manufacturers need to develop test systems that meet the technical needs of new IC products and don’t contribute to yield loss and take up the same or less factory floorspace as the generation being replaced.

High-density and high-efficiency Vicor power modules enable ATE system design engineers to implement new power delivery networks that will allow for increasing test head pin count in the same or smaller size test head. New data center, military, automotive and industrial ICs consume ever-increasing amounts of power and have many, varied voltage levels.

The Vicor modular approach to power enables ATE manufacturers to readily scale power levels and support different voltages to enable rapid development and fast time-to-market.

Industry-leading power density up to 8kW/in3

Up to 98% efficiency

Scalable PDN implementation

Sine amplitude converter topology minimizes EMI

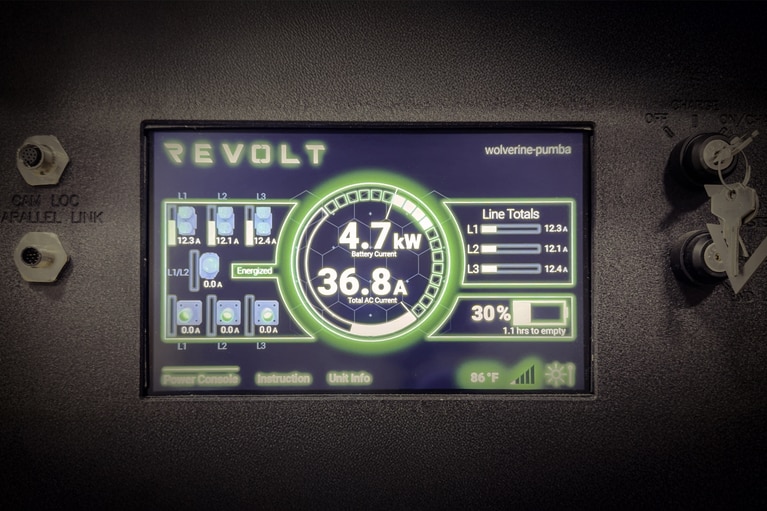

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity

Helping Hollywood fulfill its green ambitions

ReVolt is the cleaner, greener solution to the massive fossil fuel burning generators used on movie sets today. Learn how Vicor is helping ReVolt

16th Asia Power Technology Development Forum 2025

Vicor presented high-density DC–DC power modules maximize ATE throughput

Accelerate your move to a high performance 48V power delivery network

This eBook provides guidance on designing 48V power delivery networks to enhance the performance, efficiency, and reliability of industrial products