Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Highly compact power modules open up creative possibilities and offer performance and scalability far superior to discrete solutions.

By Patrick Kowalyk, Automotive FAE

Sales of electric vehicles continue to grow globally. March 2023 saw combined (BEV and PHEV) sales of over 322,000 plug-in electric vehicles registered across Europe, a 29% year-on-year increase. Furthermore, battery electric vehicles show a 44% year-on-year increase and account for a 16% share of all cars sold in Europe.[1]

These figures are good news for all vehicle manufacturers after the dismal car sales during the 2020-2021 COVID-19 period. The rebound in overall sales and the significant rise in EV sales bodes well for the future. Still there remains consumer reticence around charging infrastructure and battery range. In response, manufacturers already have second-generation EV models in production addressing consumer concerns.

There are several trends worth noting.

Still, there are other important safety and reliability enhancements needed. There is no escaping the fact that since a BEV derives all its power from a single source — the high-voltage traction battery — any interruption to it is more than inconvenient, it can pose serious safety hazards. So while creature comforts may be captivating consumers and stimulating new sales today, long term viability of the EV platform is dependent on sound safety protocols being designed into the vehicle. In an all-electric automobile power redundancy is essential.

The addition of a redundant source of energy in an EV ensures safety and reliability for its driver, passengers and other road users. Redundant power is required for three load types:

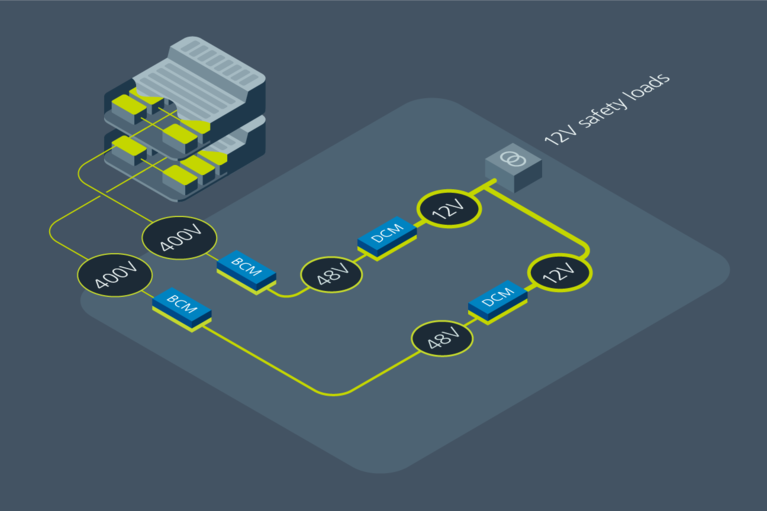

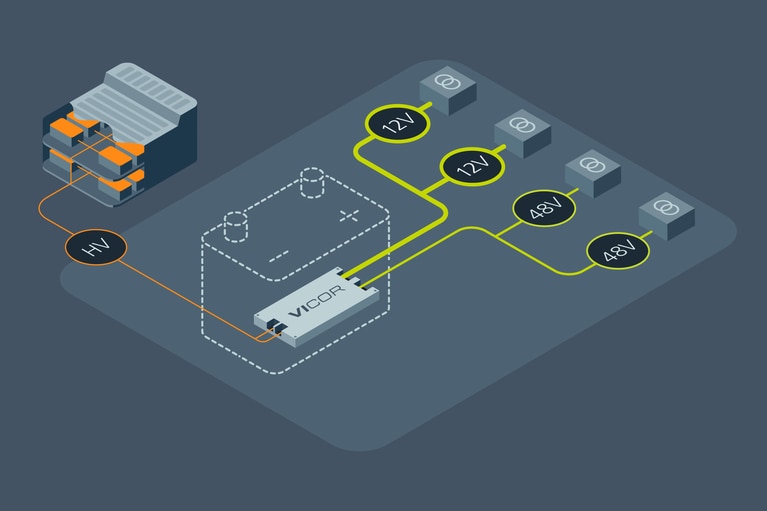

For example, EV power architects could achieve an 800V traction battery source by connecting two 400V battery packs in series, with each battery configuration having a separate DC-DC (400V to 800V) converter. This configuration (Figure 1) is called a Dual-400V series-stacked system.

Figure 1: Dual-400V series-stacked system. Connecting two 400V battery packs in series with separate DC-DC converters in a stacked architecture allows lower-voltage operation and splitting the load to two or more strings.

Some manufacturers are presently using the Dual-400V series-stacked system for several reasons. The primary reason is that charging with a 400V charger is easier because many installed public chargers are not 800V compatible. Today, as new chargers are installed, they can support both 400V and 800V batteries. The second reason is that if a manufacturer has already designed and qualified a 400V battery pack, it is faster and easier to add two packs in series.

Another approach is the Dual 800V parallel battery configuration (Figure 2) that involves using two 800V batteries in parallel. Again, two separate DC-DC converters provide redundancy.

Figure 2: Dual-800V parallel battery configuration. This configuration, allows for lower-current operation, and an easier method of implementing an N + 1 redundancy.

There are trade-offs with both configurations.

When using a Dual-400V series-stacked system these are the drawbacks to consider:

The advantages of the system are:

The Dual-800V parallel battery configuration also has some tradeoffs.

Advantages:

Disadvantages:

While relatively few vehicles currently utilize a dual 800V battery platform, the redundancy that it offers is important for safety. Without it, the most important car systems are one short away from a catastrophic event. EV power architectures are moving in this direction. Reliability and safety are the biggest reasons for the migration, but newer chargers are compatible with both 400V and 800V, which illustrates further market pull toward 800V.

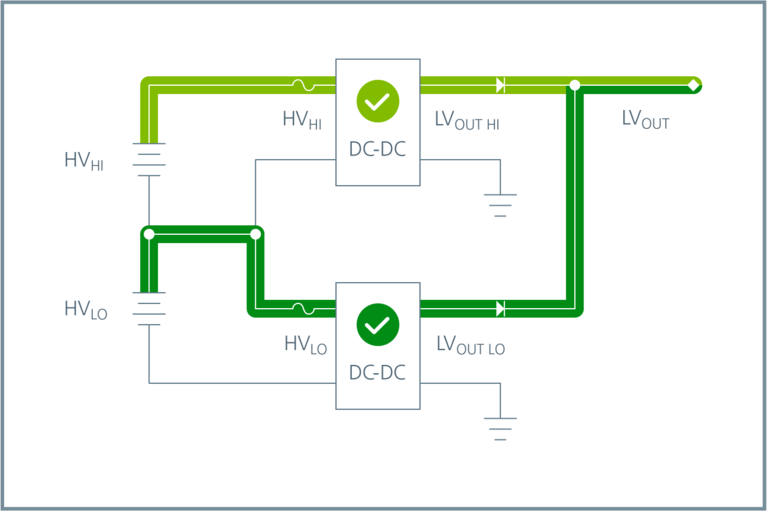

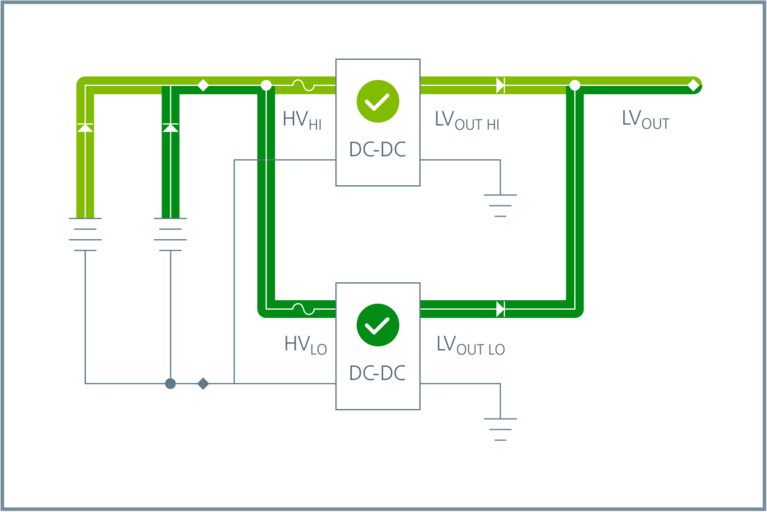

Different factors may preclude choosing one approach over another, but in most cases the Dual-800V battery configuration is preferred for one simple reason. In this system, the power modules make it easy to build in redundancy by using the batteries in parallel. This enables a second power path to the load in the event of a short, protecting the system from total shut down.

There are weight and range considerations in addition to the demand on physical space to accommodate two battery packs. While some additional circuitry is required for the battery management systems, the safety and reliability benefits outweigh that in the big picture.

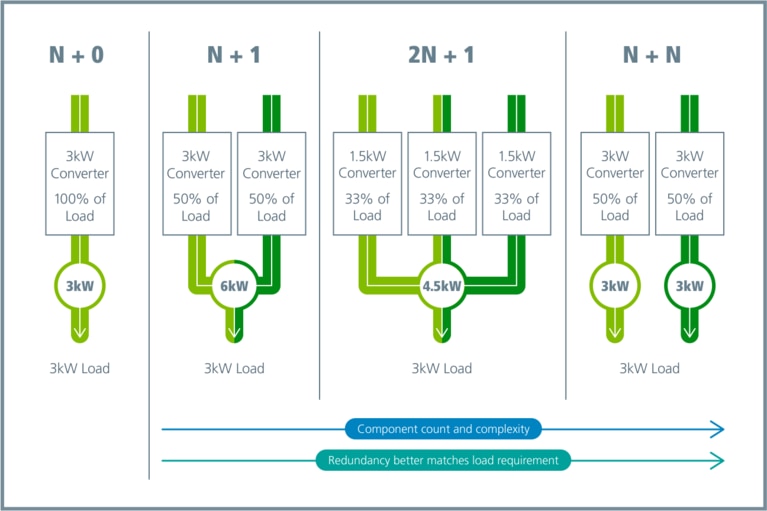

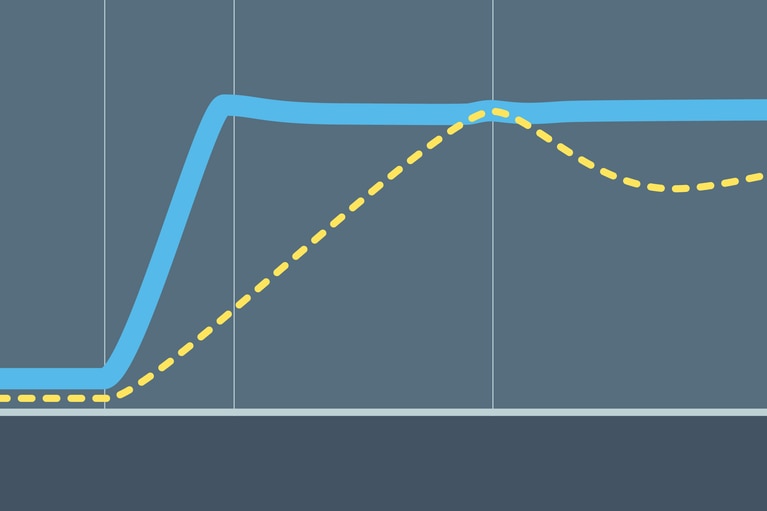

Implementing redundancy can be done in a number of ways (Figure 3). The load can be shared across two or more DC-DC converters, with the ability of a single converter to take up the entire load should one of the power sources or converters fail. Designing a robust and reliable power architecture for an electric vehicle is a challenging task. However, by introducing redundancy, manufacturers can improve vehicle safety and reliability and more importantly, consumer confidence.

Redundancy can take several forms. Look at the entire power chain from the source to the load and ask; if there would be a failure at this location or portion of the circuitry,

The objective is to be able to continue the driving journey or be able to safely exit the highway off-ramp.

Redundancy in a DC-DC converter can take many forms (Figure 3). Some examples are N + 0, N +1, 2N + 1, etc. Each configuration has advantages and disadvantages in terms of size, cost and complexity. A careful study needs to be performed for each vehicle's architecture.

Figure 3: Several combinations of redundant architectures show power levels and power split in an EV powertrain. The N + 1 has more power capability and therefore can be a larger and more expensive solution. Reading left to right, the redundancy improves and the power supply more closely matches the load’s requirement, but it also increases component count and system complexity.

By using a bidirectional DC-DC converter and separating the loads of the vehicle, power can be passed from one zone to the other. Passing the power through a regulator provides a solid source to power the load or even charge a battery.

However, today’s current converter technology is not capable of making DC-DC converters that are small and light enough to use multiple units in parallel in BEVs.

The Vicor BCM® and DCM™ power modules enable easy paralleling. Their compact size reduces the overall DC-DC converter footprint and their efficiency and density bolster performance (Figure 4). This augments vehicle range and enables new architectures to enhance safety.

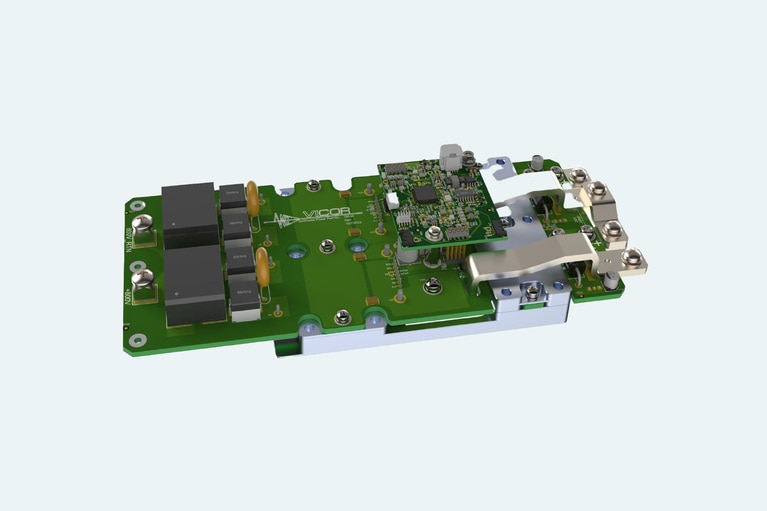

Figure 4: This 4kW DC-DC converter uses two Vicor BCM6135s and two DCM3735s (located on the underside of the board) to convert 800V power to 12V power in a package that weighs 0.08kg and in a volume of only 0.8575L. This can configured into two redundant power supplies of 2kW each, or paralleled with another unit to create a redundant 4kW power supply.

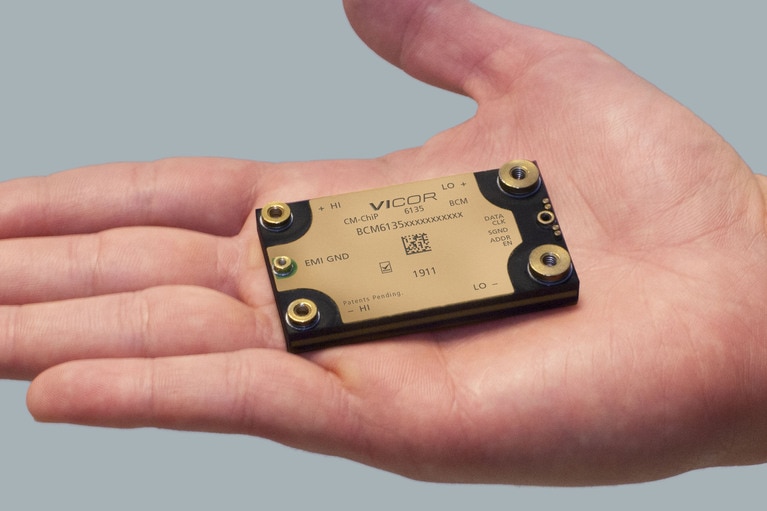

High-density power modules unlock creative opportunities and deliver performance and scalability in a way far superior to discrete solutions. Power modules provide up to 3x more power density, enable easy scalability and deliver higher transient speeds that can support down-sizing or removing the 12V/48V auxiliary battery altogether. The BCM (Figure 5) steps down the high-side voltage and multiples the current while providing isolation in a power-dense, highly efficient converter.

Figure 5: BCM® bus converter. BCMs are high-density, high-efficiency, fixed-ratio (non-regulating) isolated DC-DC converter modules. The family extends from 800V or 400V to 48V inputs with various K factors to suit a wide range of applications. The BCM provides the greatest power density for high-voltage battery conversion to low-voltage networks. The BCM product family leverages Vicor Sine Amplitude Converter™ technology that results in high-efficiency performance in miniaturized modules. Vicor develops BCMs to match the 400V or 800V battery. Vicor BCMs can be used in arrays to scale to the necessary power requirements.

The BCM is a ratiometric device, where the output is a ratio of the input by a K factor. For example, if the source is 800V in a parallel configuration, the K factor would be 1/16, therefore the low-side voltage is the high-side voltage divided by 16, and the output current is the high-side current multiplied by 16. The Dual-400V series-stacked system uses a similar BCM, however the K factor is 1/8.

Figure 6: The DCM3735 is a non-isolated, regulated DC-DC converter with an input range of 35 – 58V. It offers constant current operation for battery charging, comes in a compact package (36.6 x 35.4 x 7.4mm) and can be used in array.

The DCM3735 regulator takes the voltage from the BCM and provides a tightly regulated output that can charge a capacitor or battery (Figure 6). The combination of BCMs and DCMs enables designers the flexibility to create space and weight efficient, redundant power networks in EVs. Vicor technology can provide 4kw of 800V to 12V power supply in less than 0.9 L. As seen in Figure 4 this system weighs less than 1kg, and can enable further weight savings by enabling the downsizing of the 12V back-up battery.

Consumers want to purchase EVs, but many have reservations. At the top of the list are range and charging convenience. These are not easy problems to solve, but new innovations in power architectures and power density are helping tremendously. Compact power innovations save weight, which can improve range. Also, the introduction of power modules provides creative latitude and simpler ways to reduce size and weight, which can deliver more range.

The power module is important to solving range, reliability and safety issues. Its scalability and small size adds immense flexibility to designing a power system. When combined with innovative architectures power modules are a catalyst to rapidly advance the long-term adoption of today’s battery electric vehicles.

Sources:

[1] Kane, Mark (May 10, 2023) “Europe: Plug-In Car Sales Accelerated In March 2023”, INSIDEEVS

Patrick Kowalyk has been providing automotive power systems for over 6 years, but has been practicing engineer for decades. Patrick’s deep technical knowledge has been instrumental in growing the Vicor automotive business. His technical mastery of electrical engineering as related to power modules, topologies and architectures is second to none. Kowalyk has been a catalyst for helping design compact, efficient power systems for OEMs and Tier One customers. He holds a BS in Electrical Engineering from the Illinois Institute of Technology.

Patrick Kowalyk, Automotive FAE

Future-proof automotive high-voltage-to-SELV conversion

Legacy 12V architecture is no longer capable of sustaining the rising electronic loads in automobiles. Learn how power modules hasten the transition to 48V

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

48 volt pulsed power defrosts automobile glass in 60 seconds

Betterfrost defrosts icy auto glass in less than 60 seconds using propriety pulsed power. Learn how Vicor power modules enable this 48V innovation

Bidirectional power and transient speed enable scalable active suspension

Sine Amplitude Converter™ modules offer a unique combination of bidirectionality and transient response to unlock new possibilities for active suspension