Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

By Phil Davies, Corporate Vice President

From the first Brick to today’s ChiP™ (Converter housed in Package), Vicor has been continually innovating to deliver higher-performance solutions to power‑system engineers. These innovations are a result of a steadfast focus on advancing four essential technology pillars: power delivery architectures, control systems, topologies and packaging.

The fourth pillar, power module packaging, has been a unique differentiator for Vicor since its inception. There are several attributes that enable a high‑performance power module package, and Vicor consistently leads the industry in advancing each one:

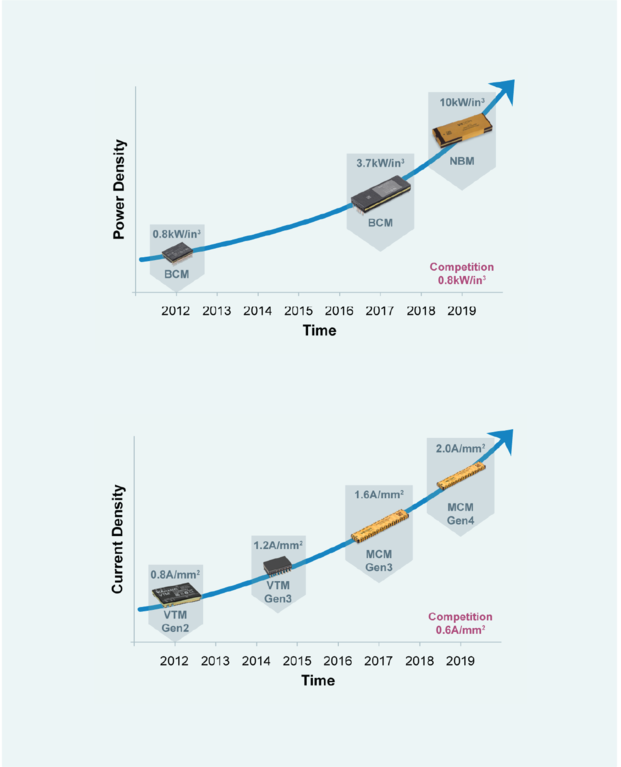

Figure 1: Continual advancements in the four pillars of innovation have reduced power losses by 25% every 2.5 years enabling significant power- and current-density improvements.

Each step of Vicor power module package development leveraged new materials, active and passive components and, most notably, improvements in magnetic structures based on higher switching frequencies. The higher frequencies are enabled by topology and control system improvements incorporated in proprietary Vicor control ASICs. The recent launch of the fourth generation (Gen4) of these ASICs has enabled power density and current density numbers of 10kW/in3 and 2A/mm2 respectively, enabling a new family of AC and DC high‑power front‑end converters and point‑of‑load (PoL) current multipliers. These latest generations of modular power solutions are changing the way power delivery networks (PDNs) are architected and designed in numerous industries.

The multi‑layer circuit boards within the power module on which components are placed are complex designs. They require special materials for optimal thermal conduction and to manage the flow of high currents and high voltages in tightly-packed spaces, all while minimizing power loss. The circuit boards also play a critical role in the assembly of the planar magnetics, which can be a source of major power loss.

Significant innovation has occurred over the years in the area of power module development. In 2015 Vicor introduced a new ChiP™ package which advanced power density with full double‑sided component placement. It delivered heat extraction from both sides of the ChiP to maximize performance and power ratings. Two years later, the introduction of the copper‑plated ChiP further advanced ChiP packaging, significantly simplifying thermal management by means of a wrap‑around copper jacket.

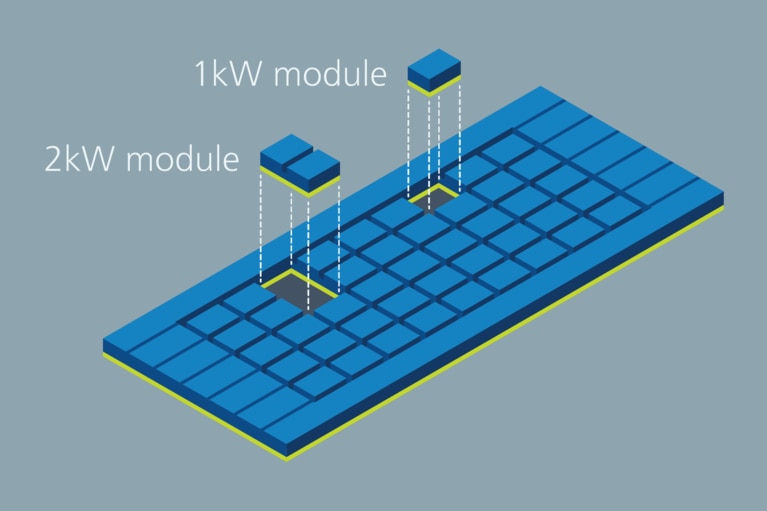

High‑voltage and high‑power Vicor fixed‑ratio converters capitalize on the thermally‑adept ChiP package by utilizing both chassis‑mount and through‑hole board‑mount package options for up to 50kW arrays of 800V-to-400V bidirectional conversion at up to 98.8% efficiency.

Materials science plays a big role in advancing power package performance, especially when switching at multiple‑MHz levels. Of the several magnetic components in a power module, some are related to the gate‑drive circuits for the main power switches and are very small, low‑power assemblies. Gate‑drive transformers play a major role in minimizing gate‑drive losses and have been optimized over many years and cycles of learning.

The main energy storage core for the converter or regulator plays the critical role in overall module performance and can be one of the main sources of power loss. The core, its windings and PCB material compositions are continually optimized for higher switching frequencies, higher power levels and lower output resistances to reduce power losses and increase efficiencies. By integrating the energy storage inductor or transformer into the power module and maximizing its performance, the power‑system designer is relieved of the often difficult and time‑consuming process of optimizing the power converter magnetics, and they can achieve a reduction in the overall power system footprint. One Vicor power module family that captures all of these critical design elements is the current multiplier, which is now powering some of the most advanced GPUs and AI processors in high‑performance computing applications. Vicor VTM™, MCM™ and GCM™ are capable of delivering over 1000 amps, while directly converting 48V to sub‑1V levels. The integrated planar magnetics in these devices have been optimized over 20 years and current multipliers now achieve current density levels of 2A/mm2 with even further advances planned for the near future.

Compatibility with high‑volume PCB assembly techniques Surface‑mount reflow soldering is used by all of the high‑volume contract manufacturers (CMs) around the world. The new Vicor SM‑ChiP is a plated, overmolded package intended for surface‑mount attachment to a printed circuit board and is compatible with CM manufacturing techniques and equipment. The electrical and thermal connections of the package are formed through soldered connections to plated castellation terminal features along the perimeter of the module and continuous plated surfaces of the main package body. SM‑ChiPs are compatible with tin‑lead and lead‑free solder alloys as well as water‑soluble and no‑clean flux chemistries; they can also be picked‑and‑placed onto the PCB. The package has also been designed to withstand multiple reflows for multi‑sided PCB assemblies. Detailed SM‑ChiP™ Reflow Soldering Recommendations are also provided by Vicor to ensure successful implementation.

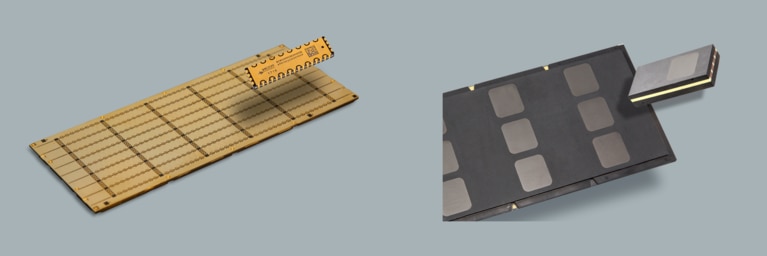

The original Vicor VI Chip® package was also an overmolded package but was manufactured using individual‑cavity construction. In contrast, the new ChiP™ is made and cut from a standard‑size panel and make full use of both sides of the module’s internal PCB for active and passive components.

Figure 2: The new panel manufacturing process was another innovation for the power industry. ChiPs are all cut from the same size panel, enabling an automated high-volume manufacturing process.

Thermal management of this package requires double‑sided cooling to maximize performance and power density. Making and cutting ChiPs from panels is very similar the way silicon chips are made and cut from wafers, but whatever the power level, current level or voltage level of the module, ChiPs are all cut from the same size panel, enabling a manufacturing operation that is streamlined, high‑volume and very scalable.

Vicor will remain on the forefront of delivering modular high-performance power delivery networks (PDNs) by continually advancing its four technology pillars of innovation: power delivery architectures, control systems, topologies and packaging. Each pillar is essential to achieving the performance that customers demand for their advanced systems development in high-performance computing, electrified vehicles, satellite communications and industrial applications. However, the power module package is where all of the elements of innovation come together, and where materials science and a great deal of ingenuity enable the critical performance metrics of density and efficiency.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

Power modules simplify creepage and clearance design solutions for electric vehicles

Overmolding is the key to solving arcing issues in 48V automotive power systems

Power under pressure: Meeting the military’s surging energy demands

More capability (power) and compatibility are in demand for military power system designers. Learn how the Vicor SOSA Power Supply solves this problem

Current multipliers: The obvious choice for powering AI processors and other demanding applications

AI processors need to handle low-voltage, high-current demand, which can cause power system bottlenecks. Learn how current multiplication can change that