Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

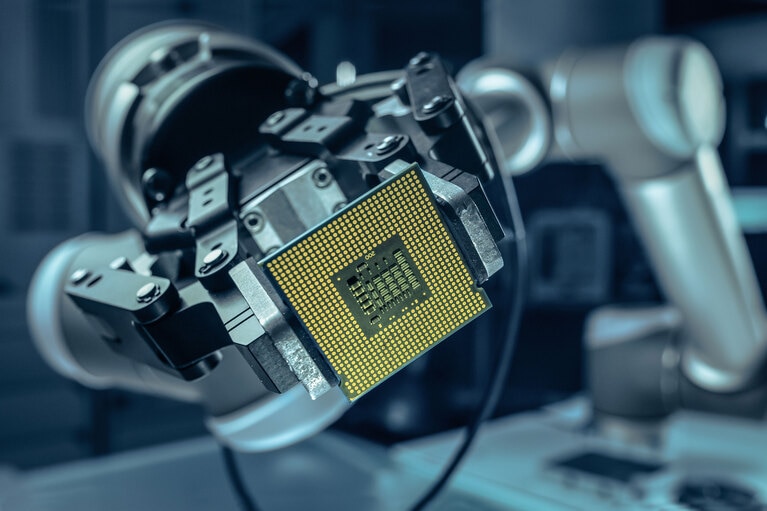

Semiconductor manufacturers rely on high-density test systems to support their growing portfolios of increasingly complex products. AI processors, CPUs, GPUs, SoCs and mobile processors are adding greater functionality including RF connectivity, power management and mixed-signal processing. To support these varied IC functions, ATE systems require advanced PDNs to handle the many different power and voltage levels.

Modularity of these testers is also becoming critical, as testers switch from testing AI processors that draw 1,000A at 1V to mixed-signal SoCs, at a fraction of the current of processors, that are extremely sensitive to EMI. The Vicor patented Sine Amplitude Conversion (SAC) topology, inherently low-noise due to its soft switching at high frequency, greatly reduces false test results due to high EMI.

Instead of attempting the difficult task of increasing the tapped-out efficiency of a front-end ATE power supply, a power delivery network was architected to use an intermediate 48V bus for better efficiency from 48V to the point-of-load. An array of two Vicor DCM3623 isolated, regulated DC-DC converter modules deliver over 600W of power at 92.7% efficiency at full load. In the same PDN, the Vicor fixed-ratio DC-DC modules transform 48V to a large variety of point-of-load requirements from 1V to 12V at 96% efficiency. The inherently low noise of Vicor SAC topology and advanced packaging technology, combined with planar magnetics and a low profile, greatly simplify and improve thermal management.

Optimizing DC-DC converter stability: AC and transient analysis in simulations of source impedance effects

Learn how to optimize DC-DC converter stability through AC analysis in the frequency-domain and transient analysis in the time-domain

15 technical challenges to consider and conquer when designing a 48V power delivery network

To help better prepare for your 48V migration, consider the following 15 challenges as you embark on your first 48V designs

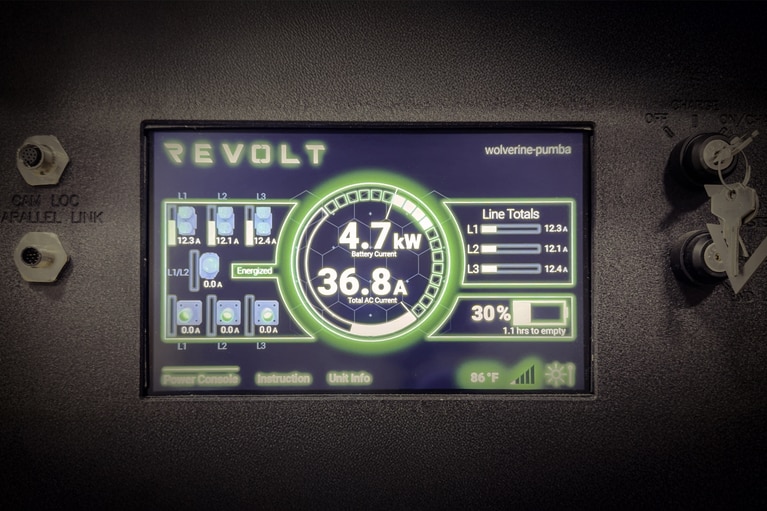

ReVolt – Technical Q&A

ReVolt is cleaning up Hollywood's emission problems today and next will address construction sites, emergency response and events with portable DC power

How ReVolt leverages Vicor technology for carbon-neutral film production

Vicor’s power converters to provide clean, mobile, and always-on electricity